Introduction to Optical Parts Processing

Optical parts processing is a specialized field that focuses on the fabrication and refinement of optical components such as lenses, mirrors, and prisms. These components play a critical role in various industries, including telecommunications, medical devices, and consumer electronics. The significance of optical parts processing stems from the increasing demand for high-performance optical components, which are essential for improving the functionality and efficiency of optical systems.

The process of optical parts processing involves several techniques tailored to meet specific requirements. These techniques can include grinding, polishing, coating, and laser engraving, each contributing to the precise and accurate production of optical components. The ultimate goal of these processes is to achieve optimal optical performance, which includes enhancing light transmission, reducing aberrations, and ensuring durability of the components. As technology continues to develop, so does the complexity and precision required in optical parts processing.

In telecommunications, for example, advanced optical components are crucial for fiber-optic communication systems, where maintaining signal integrity and minimizing losses is paramount. In the medical sector, optical parts are integral to the functioning of devices such as endoscopes and imaging systems, where precision and reliability can directly impact patient outcomes. Additionally, in consumer electronics—where demand for high-definition displays and advanced imaging technology continues to grow—optical parts processing plays a pivotal role in delivering superior user experiences.

Overall, the realm of optical parts processing is continually evolving, spurred by advancements in technology and increasing applications across various sectors. Understanding the fundamental techniques and significance of this field is essential for professionals and organizations aiming to remain competitive in an ever-changing landscape.

Material Selection for Optical Components

The process of selecting materials for optical components is crucial in determining their performance and suitability for various applications. Common materials used in optical systems include glass, plastics, and crystals, each offering unique properties that cater to specific functions in the field of optics. Understanding the characteristics of these materials is essential for optimizing their effectiveness in different optical applications.

Glass is one of the most widely used materials due to its excellent optical clarity, durability, and resistance to environmental factors. Various types of glass, such as borosilicate and crown glass, provide different refractive indices and transmission characteristics, making them suitable for a range of applications—from lens fabrication to prisms. However, the heavyweight and fragility of glass can pose challenges in certain designs, necessitating careful consideration during material selection.

Plastics, such as polycarbonate and acrylic, offer benefits such as lightweight construction and increased impact resistance. They are particularly advantageous for applications where weight is a constraint and safety is paramount, like in eyewear and protective shields. While plastics can be molded into complex shapes with ease, they may suffer from lower optical clarity compared to glass and can be more prone to scratches and degradation over time. Ultimately, the decision to use plastic over glass is influenced by the specific requirements of the optical system being designed.

Crystals like quartz and fluoride have specialized applications due to their unique optical properties, including birefringence and high damage thresholds. They are often employed in high-performance systems such as lasers and sensors. The trade-offs involved in choosing crystals include higher costs and more complex fabrication requirements, which can both affect the overall feasibility of the optical device.

The choice of material significantly impacts the processing methods employed in fabricating optical components. For instance, glass may require grinding and polishing processes, while plastics can often be directly molded into finished shapes. Balancing properties, costs, and processing capabilities is key to achieving optimal results in optical component design.

Key Optical Processing Techniques

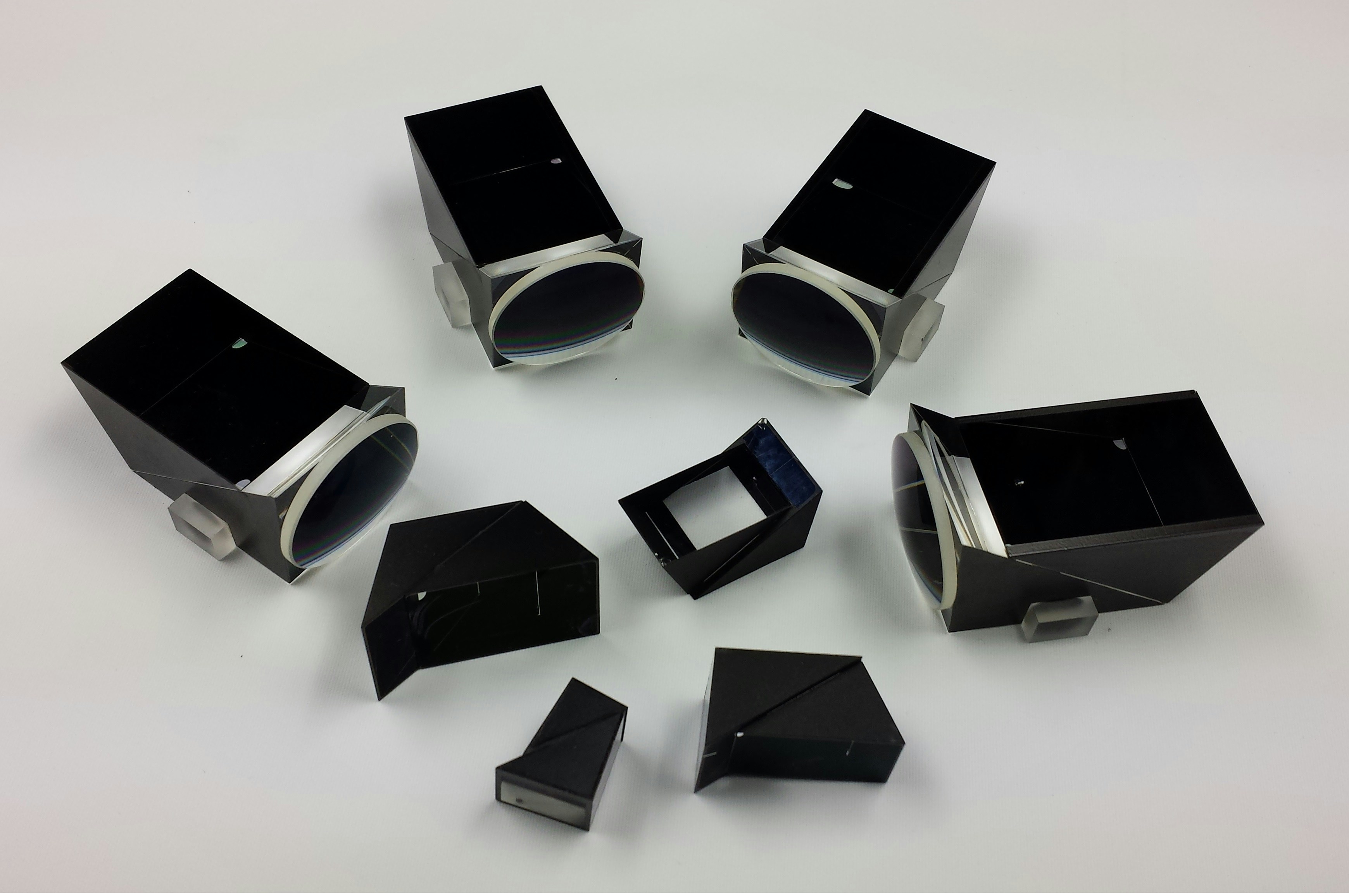

Optical parts processing encompasses a variety of techniques designed to achieve specific outcomes in the fabrication of optical components. Understanding these techniques is crucial for their effective application in various industries, including telecommunications, aerospace, and consumer electronics. Among the most significant optical processing techniques are grinding, polishing, coating, and laser machining.

Grinding is a preliminary method used primarily to shape and resize optical elements. This technique involves removing material from the surface of optical components through the use of abrasive wheels or pads. The primary advantage of grinding is its efficiency in producing rough shapes quickly. However, it comes with limitations such as the potential for surface damage and a lack of fine finish, which may necessitate subsequent polishing. Grinding is best suited for materials that require significant material removal, such as glass and certain plastics.

Polishing follows grinding and is essential for achieving a smooth, defect-free surface finish. It employs finer abrasives and is often performed using a slurry of polishing compounds. The advantages of polishing include the enhancement of optical clarity and reduction of surface roughness, making it ideal for lenses and mirrors. Nonetheless, polishing can be time-consuming, and excessive polishing may lead to dimensional changes in the optical element. Materials such as optical glass and crystals benefit most from this technique.

Coating is another critical technique used to enhance the performance of optical parts. This process involves applying thin films to optical surfaces to improve properties such as reflectivity, transmissivity, or durability. Coatings can be deposited through various methods, including vacuum deposition and chemical vapor deposition. While coatings offer increased functionality—such as anti-reflective or mirror coatings—they can be sensitive to environmental conditions and require precise application. Coatings are widely used on lenses, filters, and beamsplitters.

Lastly, laser machining is an advanced optical processing technique that utilizes laser technology for material removal. This method allows for high precision and flexibility in shaping intricate designs. The advantages include the ability to process a wide range of materials and achieve complex geometries with minimal mechanical stress. However, laser machining requires careful parameter optimization to prevent thermal damage to sensitive optical materials. This technique is particularly valuable for producing customized optical components and microstructures.

Precision and Quality Control in Optical Processing

In the realm of optical parts processing, ensuring precision and maintaining stringent quality control are paramount for achieving superior optical performance. The optical quality of components significantly affects their functionality, making it essential for manufacturers to employ a variety of measurement techniques and technologies. Among these, surface roughness measurements play a crucial role; they assess the finish of optical surfaces, which directly influences the light transmission and reflection properties critical to optical devices.

Interferometry stands out as a vital method in this domain. This optical technique measures wavefront aberrations and surface deviations with remarkable accuracy. By utilizing the interference pattern generated by coherent light sources, manufacturers can determine the exact surface profile of optical components. This capability is essential for high-precision applications, such as in the creation of lenses and mirrors, where even minute imperfections can lead to significant degradation in optical performance.

Wavefront measurement technologies have also gained prominence in ensuring the quality of optical components. These techniques evaluate how light propagates through an optical system, allowing for the detection of aberrations that might not be visible through traditional methods. Advanced systems utilize phase-shifting interferometry and Shack-Hartmann sensors, enabling manufacturers to conduct real-time assessments during the production phase. This ensures that any deviations from the desired specifications can be addressed immediately, minimizing waste and enhancing efficiency.

The integration of these precision measurement techniques into optical processing workflows not only elevates the overall quality of optical components but also instills confidence among users regarding their performance. Consequently, fostering advancements in measurement technologies will continue to be a critical area of focus within the optical manufacturing sector, paving the way for improved solutions in various applications.

Emerging Technologies in Optical Processing

The field of optical parts processing is undergoing significant transformations with the advent of several emerging technologies. Among these advancements, 3D printing of optical components stands out as a revolutionary process, allowing for the fabrication of complex geometries that were previously difficult to achieve through traditional manufacturing techniques. This innovative approach enables the production of customized optical parts with precise specifications, promoting greater efficiency and reduced waste in the manufacturing cycle.

Ultra-precision machining is another notable development in optical processing technologies. This technique involves the use of advanced machinery capable of achieving tolerances in the sub-micron range. By applying ultra-precision machining methods, manufacturers can create optical components that exhibit exceptional surface quality and dimensional accuracy. This is particularly beneficial in applications requiring high levels of performance, such as aerospace, telecommunications, and medical instruments, where the reliability of optical systems is paramount.

Furthermore, the evolution of advanced coating techniques is reshaping the landscape of optical processing. These techniques involve the application of thin film coatings that enhance the performance characteristics of optical components, such as anti-reflective properties, increased durability, and improved transmission efficiency. The development of novel materials and deposition methods has broadened the scope of coating applications, enabling significant improvements in the functionality and lifespan of optical parts.

In addition to these core technologies, advancements in computational methods and software have facilitated the design and optimization of optical components, leading to greater innovation within the industry. As these technologies continue to evolve, they promise to play a crucial role in enhancing the capabilities and applications of optical parts processing. The integration of such emerging technologies will undoubtedly drive the future landscape of the optical manufacturing sector, paving the way for more efficient production and groundbreaking applications across diverse fields.

Applications of Processed Optical Parts

Processed optical parts play a vital role in numerous applications across various industries, showcasing their versatility and critical importance. Among these applications, lasers stand out as a significant area where these optical components are essential. High-precision optical lenses, mirrors, and beam splitters are pivotal in directing and manipulating laser beams for diverse purposes, from industrial cutting and welding to scientific research and medical therapies. For instance, in laser surgery, specifically in ophthalmology, carefully engineered optical parts ensure accurate targeting and minimal invasiveness, leading to improved patient outcomes.

Another crucial domain is sensor technology, which relies heavily on processed optical parts for functionality. Optical sensors, designed to detect changes in light or other electromagnetic signals, utilize components such as photodetectors and filters. These sensors find applications in various fields, including environmental monitoring, automotive systems, and consumer electronics, effectively measuring parameters such as temperature, humidity, and chemical composition. In one notable example, optical sensors in automotive vehicles assist in adaptive cruise control by gauging the distance to other cars, enhancing road safety.

Imaging systems also extensively depend on processed optical parts for high-quality image capture and analysis. In scientific imaging, such as microscopy or astronomy, specialized optical elements enhance resolution and contrast, allowing researchers to make detailed observations. Moreover, in the field of display technologies, components like liquid crystal displays (LCDs) and organic light-emitting diodes (OLEDs) utilize processed optical parts to control light emission and improve image quality. Companies in the consumer electronics sector continually innovate, ensuring that the processed optical parts used in their products provide users with superior visual experiences.

Challenges in Optical Parts Processing

The optical parts processing industry faces numerous challenges that can significantly impact the quality and cost-effectiveness of the final products. One of the primary challenges is the need for high precision. Optical components, such as lenses and mirrors, require extremely tight tolerances to ensure they function correctly in their intended applications. Even minor deviations in dimensions or surface quality can lead to significant performance issues, particularly in high-precision fields like aerospace or telecommunications. Achieving such precision often demands advanced machining and fabrication techniques, necessitating investment in sophisticated equipment and skilled personnel.

Another critical challenge is material variability. Optical materials, ranging from glass to polymers, exhibit a wide range of properties, including refractive index, transparency, and thermal expansion. This variability can complicate the processing pipeline, as different materials may require distinct approaches and can react differently to machining processes. For instance, while certain glasses can be polished to a high optical quality relatively easily, others may be prone to chipping or cracking during cutting or forming. As a result, understanding the specific properties of each material is essential for ensuring consistent outcomes in optical parts processing.

Cost-effectiveness represents another significant challenge in the industry. As the demand for high-quality optical components grows, so too does the pressure to keep production costs under control. This often leads to a delicate balance between maintaining quality standards and implementing effective cost-saving measures. Addressing these challenges may require investing in innovative technologies, such as automated inspection systems and advanced manufacturing techniques like 3D printing or diamond machining. These advancements have the potential to enhance precision and reduce waste, offering solutions that can help mitigate the issues facing the optical parts processing industry.

Sustainability in Optical Processing

The optical processing industry faces increasing scrutiny regarding its environmental impact as it navigates the balance between technological advancement and sustainable practices. As the demand for optical components grows, it becomes imperative for manufacturers to adopt sustainable practices that minimize waste, promote recycling, and foster eco-friendly processing methods. A critical aspect of environmental responsibility in optical parts processing is waste reduction. Implementing lean manufacturing principles can substantially decrease material waste throughout the production cycle, leading to more efficient use of resources. Streamlining processes not only enhances operational efficiency but also mitigates the industry’s carbon footprint.

Another essential factor is the recycling of materials used in optical components. The industry traditionally relies on a variety of materials, some of which may not be biodegradable. By promoting the use of recyclable materials and establishing comprehensive recycling programs, manufacturers can significantly reduce landfill contributions. For example, the development of closed-loop recycling systems can ensure that materials such as glass and plastics are reprocessed and repurposed instead of disposed of, thus extending their life cycle and minimizing environmental harm.

Moreover, innovations in eco-friendly processing methods are pivotal to the future of optical parts processing. Techniques such as laser machining and additive manufacturing not only enhance precision but often consume less energy than conventional methods. Research into biodegradable polymers and alternative materials also stands to revolutionize the industry, enabling the creation of optical components that are not only functional but also environmentally conscious. The integration of sustainability into the optical processing landscape is not merely a trend; it reflects a commitment to responsible stewardship of the environment while maintaining the technological advancements that drive the industry. Continued efforts toward sustainable practices will be vital as the sector evolves.

Future Trends in Optical Parts Processing

The optical parts processing industry is at the brink of a transformative phase, driven by technological advancements, rising demand for high-performance optical systems, and an increasing emphasis on sustainability. One prominent trend is the integration of artificial intelligence (AI) and machine learning (ML) into manufacturing processes. These technologies are expected to enhance precision, reduce defects, and streamline production lines by predicting the performance and quality of optical components in real-time. This advancement could lead to a more adaptive and efficient workflow, ultimately diminishing production costs.

Moreover, the demand for smaller, more compact optical devices is on the rise, particularly in consumer electronics and telecommunications. As miniaturization continues, manufacturers must evolve their processes to produce high-quality optics at microscale levels. Techniques such as advanced lithography and nanoimprinting are anticipated to gain traction, enabling the creation of intricate optical components with unprecedented performance characteristics.

Sustainability is another critical consideration that will shape the future of optical parts processing. As industries increasingly emphasize environmentally friendly practices, the optical manufacturing sector is also expected to focus on sustainable materials and energy-efficient production methods. The move towards biodegradable materials in optical components, for instance, could significantly reduce the ecological footprint of optical manufacturing. Additionally, recycling programs for optical parts are anticipated to become more common, fostering a circular economy.

Lastly, the ongoing development of new materials—such as photonic crystals and metamaterials—will open new avenues for research and applications in optics. These innovative materials possess unique characteristics that can be leveraged in designing next-generation optical systems, expanding the boundaries of what is achievable. The future of optical parts processing appears promising, with significant advancements likely to reshape the industry landscape significantly.

**mitolyn official**

Mitolyn is a carefully developed, plant-based formula created to help support metabolic efficiency and encourage healthy, lasting weight management.