Introduction to CNC Machining

CNC machining, or computer numerical control machining, represents a significant advancement in the field of manufacturing. This technology utilizes computers to control machine tools, replacing the manual processes traditionally employed in crafting precision parts. The shift from conventional machining to CNC machining has revolutionized manufacturing by enhancing the efficiency, consistency, and accuracy of production. By leveraging computer algorithms and high-tech machinery, manufacturers can create intricate designs that would be nearly impossible to achieve with manual methods.

Historically, machining involved operators who adjusted machinery by hand, a process fraught with possibilities for human error. Over time, the introduction of CNC technology marked a pivotal evolution. The automation afforded by CNC enables the execution of complex tasks with high precision, addressing the substantial demand for accuracy in various industries, including aerospace, automotive, and electronics. This transition ensures that parts are produced within strict tolerances, ultimately yielding higher-quality products.

The significance of precision in CNC machining cannot be overstated. Accuracy is essential, particularly in industries where even the slightest deviation can lead to failures, inefficiencies, or safety hazards. Components must interlock perfectly in assemblies, making the reliability of CNC machining indispensable. The technology accommodates a diverse range of materials—from metals to plastics—demonstrating versatility that rivals traditional machining methods. Furthermore, it allows for rapid prototyping and production runs of varying sizes, catering to both small businesses and large-scale operations.

As industries evolve and their requirements become more complex, CNC machining remains at the forefront, continuously adapting to incorporate innovations in materials, techniques, and design. Understanding CNC machining and its impact on manufacturing is paramount for anyone involved in production, whether they are engineers, designers, or managerial staff. This foundational knowledge lays the groundwork for exploring the future of precision CNC parts in the manufacturing landscape.

What Are Precision CNC Parts?

Precision CNC parts are components produced through computer numerical control (CNC) machining, a method that ensures high accuracy and repeatability in manufacturing. These parts are characterized by their exceptional tolerances, typically measured in microns, which often range from ±0.005 mm to ±0.1 mm. Such fine tolerances are essential for applications where the fit and function of parts can significantly impact the overall performance and reliability of machinery and assemblies.

Manufacturers utilize a variety of materials to create precision CNC parts, including metals like aluminum, stainless steel, and titanium, as well as plastics such as nylon and polycarbonate. The choice of material depends highly on the intended application and the specific properties required, such as weight, strength, or corrosion resistance. Additionally, advanced manufacturing techniques, including milling, turning, and electrical discharge machining (EDM), contribute to the production of high-quality parts that meet stringent industry standards.

In terms of categories, precision CNC parts can be divided into several types, such as fasteners, brackets, housings, gears, and shafts. Each of these components plays a crucial role in various industries, including automotive, aerospace, medical, and electronics. For example, precision gears are critical in ensuring the accurate operation of transmission systems, while brackets provide essential support in structural applications. Consequently, the role of precision CNC parts in manufacturing cannot be overstated, as they are integral to the functionality and efficiency of countless products.

The Process of Precision CNC Machining

Precision CNC machining is a sophisticated technique that leverages numerically controlled machines to manufacture intricate parts. This process begins with the concept and design phase, where Computer-Aided Design (CAD) software plays a crucial role. CAD enables engineers and designers to create detailed 2D and 3D models of the required part, ensuring that every dimension and specification is accurately represented. These digital models serve as the foundation for the subsequent manufacturing steps.

Once the design has been finalized, the file is converted into a format compatible with Computer-Aided Manufacturing (CAM) systems. CAM software is integral to the CNC machining process, as it translates the CAD models into a set of instructions that the CNC machines utilize to execute the machining operations. This conversion ensures precision and accuracy throughout production, reducing the likelihood of errors.

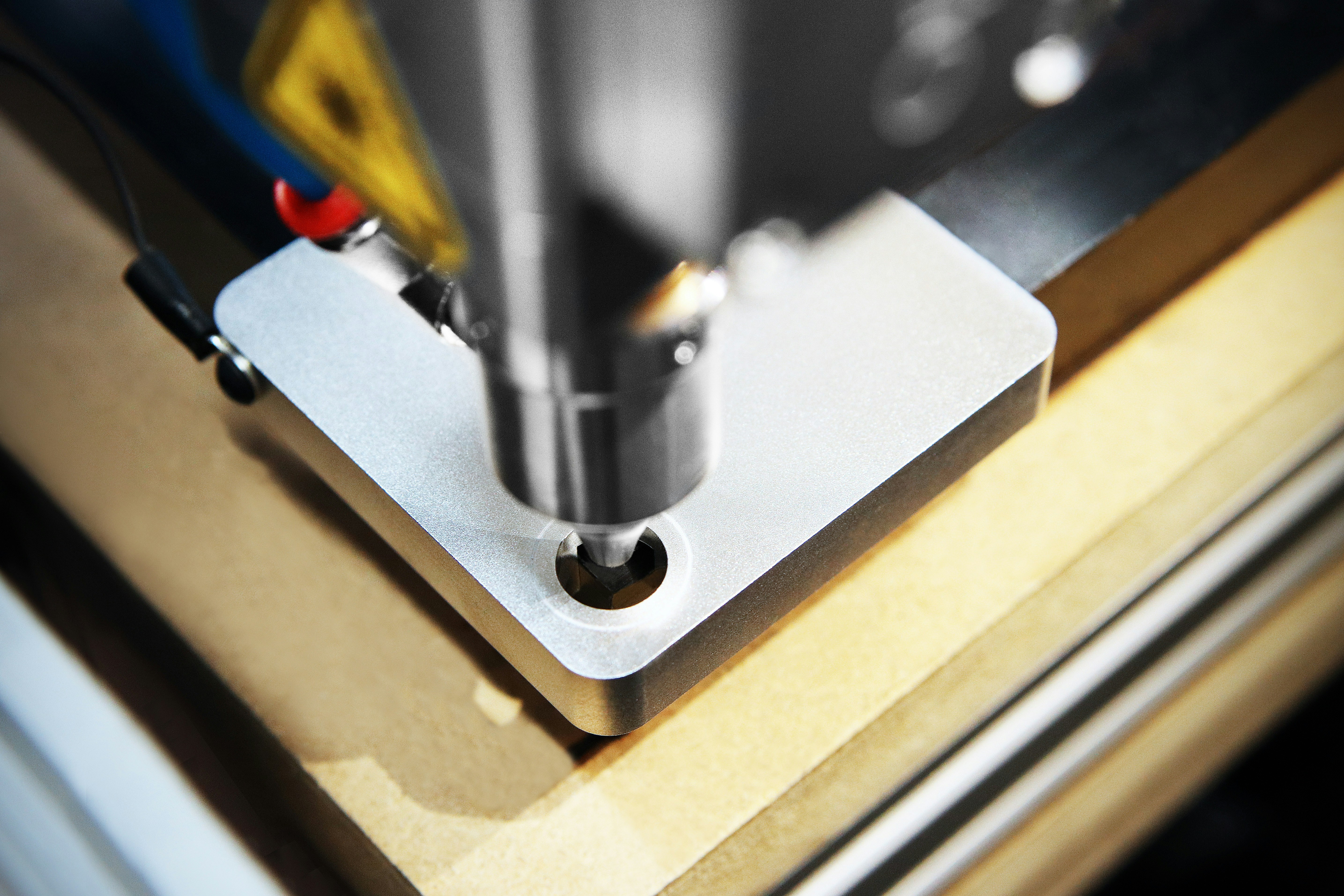

The actual machining process encompasses several operations, including milling, turning, and drilling. Milling involves the removal of material from a workpiece using rotating cutting tools, allowing for the creation of complex geometries and surface finishes. Turning, on the other hand, is a process where the workpiece rotates while a stationary cutting tool removes material, producing cylindrical shapes. Drilling is utilized to create holes in components, which can be further refined through additional operations such as tapping and reaming for threaded applications.

Throughout these processes, CNC machines maintain high levels of accuracy and repeatability, crucial for industries that demand precision, such as aerospace, automotive, and medical device manufacturing. The careful integration of CAD and CAM methodologies, along with various machining techniques, culminates in the creation of precision CNC parts that meet stringent quality standards and specifications.

Materials Used in Precision CNC Machining

Precision CNC machining involves the utilization of various materials, each selected based on specific properties that align with application requirements. The predominant materials used in this manufacturing process include metals, plastics, and composites, each possessing unique characteristics that make them suitable for different applications.

Metals, such as aluminum, steel, and titanium, are frequently employed in precision CNC machining due to their exceptional strength, durability, and thermal resistance. Aluminum is lightweight and corrosion-resistant, making it ideal for applications in the aerospace and automotive sectors. Steel, particularly stainless steel, offers a good balance of strength and ductility, rendering it useful for components that must endure high stress. Titanium, known for its high strength-to-weight ratio and remarkable resistance to heat and corrosion, is often chosen for high-performance applications in medical and aerospace industries.

On the other hand, plastics like polycarbonate, nylon, and acrylic are increasingly popular in precision CNC machining. These materials are lightweight, cost-effective, and boast good chemical resistance. Polycarbonate, for instance, is well-regarded for its impact resistance and optical clarity, making it suitable for protective equipment and housings. Nylon offers excellent wear resistance and is commonly used in gears and mechanical components due to its self-lubricating properties. Acrylic is frequently utilized in applications requiring transparency and aesthetic appearance, such as displays and signage.

Additionally, composite materials, which combine two or more constituent materials, are gaining traction in precision CNC machining. These materials can be engineered to achieve specific properties such as enhanced strength-to-weight ratios and improved thermal stability. Factors influencing material choice include not only mechanical properties but also cost-effectiveness and weight considerations, which are critical in modern manufacturing processes. By selecting the appropriate materials, manufacturers can enhance the performance and longevity of precision CNC parts, catering to diverse industry needs.

Key Industries Utilizing Precision CNC Parts

Precision CNC parts play a significant role in various industries, each with unique requirements that necessitate high levels of accuracy and reliability. Among these industries, aerospace stands out as a leading sector that benefits from precision machining. Aerospace components demand exceptional precision due to the stringent safety and performance standards that aircraft and spacecraft must meet. For instance, turbine blades and fuselage structures are often produced using CNC machining techniques to ensure the dimensional accuracy and structural integrity necessary for safe operation.

Another key industry that leverages precision CNC parts is the automotive sector. In this field, manufacturers require intricate components such as engine blocks, gear housings, and transmission parts, which must fit perfectly within complex assemblies. Precision machining allows for the mass production of these parts with consistency, thereby improving vehicle performance and longevity. Examples of precision automotive components include custom pistons and camshafts that are designed for optimal efficiency and power.

The medical industry also greatly benefits from precision CNC parts, particularly in the production of specialized instruments and implants. Components such as surgical tools, dental devices, and prosthetics require not only high precision but also biocompatibility. Using CNC machining, manufacturers can create tailored solutions that meet specific medical needs, enhancing patient outcomes and procedural success. For instance, customized orthopedic implants can be precisely designed based on individual anatomical specifications, improving the fit and function for patients.

Lastly, the electronics industry utilizes precision CNC parts to produce various components such as circuit boards, connectors, and housings. The rapid pace of technological advancement in this sector demands that manufacturers produce high-quality parts that are both lightweight and durable. CNC machining facilitates the manufacture of intricate designs needed for electronics, ensuring that devices operate efficiently and reliably.

Benefits of Precision CNC Parts in Manufacturing

Precision CNC parts have emerged as a cornerstone of modern manufacturing, offering distinct advantages that contribute to the efficiency and quality of production processes. One of the primary benefits is the enhancement of production efficiency. CNC (Computer Numerical Control) machining enables manufacturers to automate and standardize processes, which significantly reduces the time required for production. This automation not only speeds up the fabrication of components but also ensures consistency in quality, allowing companies to meet higher production demands without compromising on standards.

Moreover, the use of precision CNC parts helps in the reduction of waste. Traditional manufacturing methods often produce a significant amount of scrap material due to their reliance on manual handling and less precise machinery. However, CNC machines utilize advanced technology to create parts with remarkable accuracy, minimizing material waste and optimizing the use of resources. Consequently, this leads to a more sustainable manufacturing process that aligns with the growing emphasis on environmental responsibility.

Another notable advantage is the improvement in product quality. Precision CNC machining allows for tighter tolerances and superior surface finishes that are vital in producing high-performance components. The precision achieved in machining translates directly into the reliability and functionality of the final products, which can fulfill stringent industry standards and customer expectations. Additionally, the ability to produce complex geometries is a significant benefit of precision CNC parts. This feature enables manufacturers to create intricate designs that would be incredibly challenging or even impossible to achieve with traditional methods.

Lastly, the economic benefits of implementing precision CNC components cannot be overlooked. While the upfront costs of CNC machinery may be high, the long-term savings and increased productivity often result in a favorable return on investment. As manufacturers continue to seek efficiency and excellence in their operations, the adoption of precision CNC parts stands out as a pivotal strategy for success in today’s competitive landscape.

Quality Control in Precision CNC Machining

Quality control plays a critical role in the realm of precision CNC machining, ensuring that manufactured parts adhere to the established specifications and tolerances. The precise nature of CNC machining necessitates robust quality assurance practices to maintain high standards in production. Various measures are implemented throughout the machining process to guarantee that each part meets the requisite quality benchmarks.

One fundamental aspect of quality control in this industry is the implementation of rigorous inspection techniques. These methods can include visual inspections, dimensional checks using calipers or micrometers, and coordinate measurement machine (CMM) assessments, among others. Each of these techniques aids in verifying that the precision CNC parts are manufactured to tolerance levels, ensuring consistency and reliability. Furthermore, advanced technologies such as laser scanning and computer vision systems are increasingly utilized to enhance inspection accuracy.

Additionally, certification standards exist to validate the quality of the processes used in precision CNC machining. Standards such as ISO 9001 provide a framework for quality management systems, driving manufacturers to adopt best practices. Compliance with these standards not only elevates product quality but also fosters customer trust in the consistency of deliverables. Continuous monitoring and auditing of machining processes further reinforce adherence to these certification standards.

Moreover, real-time feedback loops can be established within the manufacturing process to catch deviations immediately, mitigating the risks associated with defects in CNC parts. Employing statistical process control (SPC) allows manufacturers to track production metrics and identify trends that may lead to quality issues. By integrating these quality control measures, manufacturers can ensure that precision CNC parts are produced reliably, ultimately contributing to the overall excellence in manufacturing and satisfying customer requirements.

Future Trends in Precision CNC Machining

The landscape of precision CNC machining is rapidly evolving, driven by advancements that are reshaping the way manufacturers operate. One of the most significant trends is the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) into CNC machining processes. By harnessing AI, manufacturers can analyze large volumes of data to identify inefficiencies, predict maintenance needs, and optimize production schedules. This not only enhances operational efficiency but also significantly reduces downtimes, leading to increased productivity in precision parts manufacturing.

Another trend gaining traction is automation in precision CNC machining. Automation technologies such as robotic arms and automated material handling systems are being increasingly adopted. These innovations minimize the reliance on manual labor, ensuring consistent quality and precision across the production line. With enhanced automation, manufacturers are able to streamline their workflows, reduce waste, and improve overall throughput of CNC machined parts.

In addition, advancements in materials science are shaping the future of precision CNC machining. The development of new, high-performance materials allows for the production of parts that are not only lighter but also stronger and more resistant to environmental factors. This is particularly relevant for industries such as aerospace and automotive, where the performance and durability of components are critical. New materials facilitate the creation of intricate designs that were previously unattainable, expanding the capabilities of CNC machining.

Furthermore, sustainability is becoming a central focus for manufacturers. With growing awareness of environmental issues, precision CNC machining is adapting practices that reduce energy consumption and waste generation. This includes utilizing biodegradable lubricants, recycling scrap metal, and seeking out energy-efficient machinery. The future of precision CNC machining not only aims to enhance performance but also to embrace sustainable practices that align with global environmental goals.

Conclusion

Precision CNC parts have emerged as a cornerstone of modern manufacturing, significantly impacting productivity, quality, and efficiency across various industries. The advancements in computer numerical control technology have enabled manufacturers to produce intricate and precise components consistently, catering to the increasing demands for accuracy in design and functionality. From aerospace to automotive, the role of precision machining cannot be understated; it has been pivotal in driving innovation and enhancing operational capabilities.

The importance of precision CNC parts lies in their ability to meet stringent tolerances and specifications, which are critical for ensuring the reliability and performance of finished products. As industries evolve, so too must the methods employed to create these essential components. The integration of sophisticated software and machinery has transformed traditional manufacturing processes, allowing for greater flexibility and customization without compromising the quality of the final output.

Furthermore, the continuous evolution of precision CNC technology highlights its relevance not only in current applications but also in future developments. As industries face growing pressure to deliver superior products while reducing lead times and costs, the adoption of precision CNC parts becomes more vital. This commitment to innovation fosters a competitive advantage and drives economic growth, emphasizing the need for manufacturers to stay abreast of technological advancements.

In conclusion, precision CNC parts play an indispensable role in the modern manufacturing landscape. Their significance will only grow as technology continues to advance, underscoring the importance for industries to embrace these changes. By leveraging the capabilities of precision machining, manufacturers can enhance their production processes, leading to higher quality products and a stronger foothold in an increasingly competitive market.