Introduction to CNC Machining in the Medical Field

Computer Numerical Control (CNC) machining has emerged as a critical innovation in the medical field, transforming the landscape of healthcare manufacturing. This advanced technology utilizes computer software to control machine tools, enabling precise manufacturing processes that are crucial for medical applications. The significance of CNC machining in the medical sector cannot be overstated; it enables the production of intricate medical devices and components with unparalleled accuracy, thereby enhancing the overall quality of healthcare solutions.

The healthcare industry demands precision in manufacturing, as even the slightest deviation can lead to compromised performance and safety. CNC machining addresses this need by offering an automated solution that minimizes human error, leading to high-quality products that meet exact specifications. This capability is particularly important in creating devices such as surgical instruments, prosthetics, and implants, where precision is paramount. Thanks to CNC machining, manufacturers can produce components that adhere to stringent regulatory standards, ensuring patient safety and efficacy.

Furthermore, CNC technology contributes to increased efficiency and reduced production times. Traditional manufacturing methods often involve manual labor, which can be time-consuming and less efficient. In contrast, CNC machining streamlines operations, allowing for the rapid production of medical devices without sacrificing quality. This efficiency is not only beneficial from a manufacturing perspective but also from a cost standpoint, making advanced healthcare solutions more accessible. Additionally, CNC machining supports customization, enabling healthcare providers to tailor medical devices to individual patient needs, enhancing personalized medicine capabilities.

In summary, CNC machining plays a transformative role in the medical field by revolutionizing the way medical devices are manufactured. With its precision, efficiency, and ability to support customization, this technological advancement is significantly enhancing healthcare delivery and improving patient outcomes.

Understanding the Basics of CNC Machining

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes computer technology to control machine tools with high precision. This sophisticated technique modernizes the traditional methods of machining, which typically relied on manual programming and operation. In CNC machining, a computer program dictates the movements of machinery, allowing for exceptional accuracy and repeatability, making it an invaluable asset across various sectors, including healthcare.

The process begins with the creation of a digital design, usually generated with Computer-Aided Design (CAD) software. This design is then converted into a CNC program using a specific programming language, often G-code. The CNC machine interprets this code to direct the tool’s movements along multiple axes. With the potential for 3D machining, CNC systems can create intricate shapes and dimensions that are difficult to achieve through manual machining methods.

One of the key advantages of CNC machining over traditional methods lies in its ability to produce complex parts with minimal human intervention. Traditional machining often requires skilled labor for setup and operation, which can introduce variability and potential errors. CNC machining mitigates these issues through its automated capabilities, leading to reduced production time and enhanced consistency in the final product.

Moreover, CNC machining is characterized by its versatility. It can operate on various materials, such as metals, plastics, and composites, making it suitable for crafting a wide range of healthcare applications, from surgical instruments to custom prosthetics. The precision offered by CNC technology ensures that the components produced meet stringent healthcare standards, ultimately supporting advancements in the medical field.

In essence, CNC machining combines technology and engineering principles to streamline the manufacturing process, making it a pivotal component in the revolution of healthcare manufacturing.

Applications of CNC Machining in Medicine

CNC machining has made significant inroads into the medical sector, facilitating a range of applications that demonstrate both precision and innovation. One of the primary uses of CNC machining is in the production of surgical instruments. These instruments require high levels of accuracy and reliability, ensuring they perform effectively during critical surgical procedures. CNC machines can manufacture instruments such as scalpels, forceps, and clamps with exact dimensions, improving their functionality and safety for patients.

Another prominent application is the development of orthopedic implants. Medical CNC machining allows for the creation of custom implants tailored to the anatomical requirements of individual patients. For instance, knee and hip prosthetics can be produced using CNC technology to match the unique contours of a patient’s joint. This bespoke approach not only enhances the fitting process but also improves patient outcomes by minimizing complications associated with ill-fitting implants.

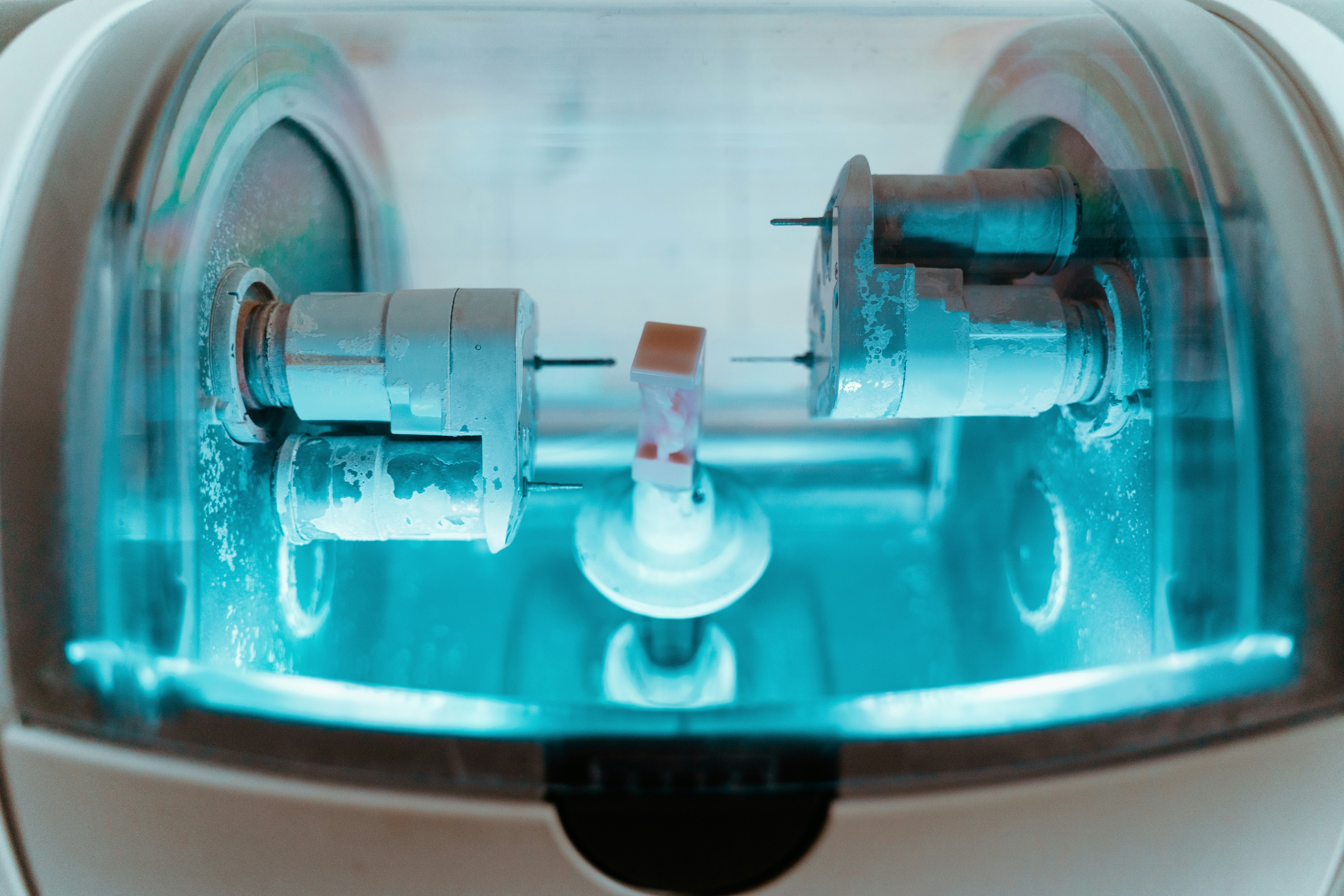

Dental devices represent another sector where CNC machining plays a vital role. With the capability to produce crowns, bridges, and orthodontic appliances, CNC technology allows for rapid prototyping and manufacturing. These devices are often made from durable materials that can withstand the oral environment, and CNC machining ensures that each piece meets the stringent standards required for dental applications.

Moreover, custom prosthetics are increasingly being created through CNC machining. Patients with limb loss or deformities benefit from prosthetic devices that are meticulously designed to fit their specific needs, thus enhancing mobility and comfort. The ability of CNC machines to create complex shapes and structures means that prosthetics can be both functional and aesthetically pleasing.

In summary, the applications of CNC machining in medicine are diverse and impactful, ranging from surgical instruments to custom orthopedic solutions. The technology not only improves manufacturing efficiency but also significantly enhances patient care by providing tailored medical devices designed with precise specifications.

Benefits of CNC Machining for Medical Devices

CNC (Computer Numerical Control) machining has emerged as a transformative technology in the manufacturing of medical devices, delivering several advantages that significantly enhance product quality and production efficiency. One of the primary benefits of CNC machining is its unrivaled precision. Medical devices often require intricate designs and tolerances that are crucial for their functionality and safety. CNC machines utilize computer-controlled processes that enable manufacturers to achieve highly accurate dimensions and surface finishes, thereby ensuring that the devices meet stringent regulatory standards.

Another notable advantage of CNC machining is the reduction in production time. Traditional manufacturing methods often involve multiple machining steps and manual labor, which can be time-consuming. In contrast, CNC machining allows for rapid production of parts as the machine can operate continuously with minimal downtime. This efficiency not only accelerates the manufacturing process but also facilitates quicker market entry for new medical devices, ultimately benefiting healthcare providers and patients alike.

Cost-effectiveness is yet another compelling benefit of using CNC machining for medical device manufacturing. While the initial investment in CNC technology can be significant, the long-term savings are substantial due to reduced labor costs, minimized waste, and decreased material consumption. Furthermore, CNC machining provides the capability for large-scale production runs, enabling manufacturers to meet high demand without sacrificing quality, which can lead to decreased unit costs.

Finally, one of the key advantages of CNC machining is the increased capability for customization. In a field where individual patient needs often require tailored solutions, the flexibility of CNC machines allows manufacturers to produce custom parts or modify existing designs with relative ease. This ability to adapt quickly to market demands makes CNC machining a preferred choice for medical device manufacturers striving for innovation and excellence.

Challenges in Medical CNC Machining

The integration of CNC machining in the medical field has proven to be transformative, yet it is fraught with challenges that manufacturers must navigate meticulously. One of the primary hurdles is the stringent regulatory compliance essential for medical devices. Various governing bodies, such as the FDA in the United States, impose rigorous standards that must be met to ensure product safety and efficacy. This compliance requires manufacturers to maintain detailed documentation and execute comprehensive testing protocols, which can lead to extended production timelines and increased costs.

Another critical challenge is the selection of appropriate materials for CNC machining. Medical devices often demand materials that meet specific biocompatibility and durability criteria. These requirements limit the range of materials that can be utilized, complicating the decision-making process. Additionally, the mechanical properties of materials can significantly affect the performance and longevity of medical devices, further complicating material selection. This challenge necessitates a deeper understanding of material science to ensure the right choices are made for specific applications.

Moreover, the demand for high quality and safety standards in the medical industry adds another layer of complexity. Precision is paramount in CNC machining for medical applications; even the slightest deviation can lead to catastrophic failures. Manufacturers must implement stringent quality control measures to monitor production processes continually to uphold these standards. This requirement necessitates advanced technology and skilled personnel, which can strain resources and increase operational costs.

In conclusion, while CNC machining has the potential to revolutionize healthcare by improving the manufacturing capabilities of medical devices, it is essential to consider the myriad of challenges each manufacturer must confront. Successfully navigating these complexities is crucial for the advancement and reliability of medical technology in today’s healthcare landscape.

Quality Control and Standards in Medical CNC Machining

The integration of quality control processes in medical CNC machining is critical for ensuring that medical devices meet strict safety and effectiveness standards. In this highly regulated industry, adherence to established guidelines is non-negotiable. One of the most widely recognized standards is ISO 13485, which outlines the requirements for a comprehensive quality management system specifically designed for organizations involved in the medical device sector. This certification serves as a benchmark for companies, necessitating that they consistently provide medical devices that meet customer and regulatory requirements.

In addition to ISO 13485, the U.S. Food and Drug Administration (FDA) imposes further regulations on manufacturers, including stringent guidelines for the design, production, and maintenance of medical devices. Compliance with FDA guidelines ensures that products are safe for use and effective in their intended functions. This includes rigorous testing and validation processes throughout the manufacturing lifecycle, from initial design stages to final production.

Quality control in medical CNC machining also involves the implementation of risk management practices as outlined by ISO 14971, which focuses on the identification and mitigation of risks associated with medical device use. This proactive approach minimizes the likelihood of defects while maximizing patient safety. Furthermore, additional standards such as IEC 60601 address the safety and effectiveness of medical electrical equipment, further bolstering the framework for quality assurance in the industry.

The importance of continuous monitoring and improvement cannot be overstated, as it ensures that medical CNC machining practices evolve alongside advances in technology and materials. Regular audits and assessments instill confidence in manufacturers’ capabilities to deliver high-quality medical devices. By maintaining adherence to these rigorous standards and certifications, medical CNC machining companies can significantly contribute to the prevention of errors and the enhancement of patient care outcomes.

The Future of CNC Machining in Healthcare

As the medical industry continues to evolve, the role of CNC machining is poised to undergo significant transformations that will reshape how healthcare solutions are developed and delivered. One promising direction is the increased utilization of automation within CNC machining processes. Automation not only enhances precision but also allows for the efficient mass production of medical devices, thereby reducing both manufacturing time and costs. In turn, this could lead to more affordable healthcare solutions, helping to bridge the gap between innovative medical technologies and patient accessibility.

Advancements in materials science also play a crucial role in the future of CNC machining for healthcare applications. Manufacturers are increasingly exploring the use of biocompatible and lightweight materials that can improve the functionality and comfort of medical devices. These innovative materials can be tailored to meet specific medical needs, further enhancing patient outcomes. Moreover, the integration of smart materials that respond dynamically to environmental stimuli promises to bolster the functionality of implants and other healthcare products.

Another notable trend is the convergence of CNC machining with other cutting-edge technologies, particularly 3D printing. The synergy between these two manufacturing techniques can lead to the creation of complex geometries and customized medical devices that traditional manufacturing methods may struggle to achieve. For instance, while CNC machining excels in producing precise components, 3D printing offers unparalleled design flexibility, enabling the production of patient-specific implants and prosthetics. This collaborative approach not only enhances the overall efficacy of healthcare devices but also paves the way for breakthroughs in personalized medicine.

In conclusion, the future of CNC machining in the healthcare sector looks promising, driven by continuous advancements in automation, materials science, and the integration of new technologies. Embracing these developments will likely lead to enhanced patient care, improved medical device production, and ultimately, a more innovative healthcare landscape.

Case Studies: Success Stories in Medical CNC Machining

Medical CNC machining has made significant strides in enhancing the efficiency and precision of healthcare delivery. The following case studies exemplify the successful implementation of CNC technology across various medical settings, demonstrating its impact on patient outcomes and operational efficiencies.

One noteworthy example comes from a leading orthopedic device manufacturer that integrated CNC machining into their production line for customized implants. By utilizing advanced CNC milling techniques, the organization was able to produce patient-specific prosthetics with unparalleled precision. This innovation not only improved fit and comfort for patients but also reduced surgical time, leading to faster recovery periods. The ability to create individualized devices significantly decreased post-operative complications, further validating the effectiveness of CNC technology in enhancing patient care.

Another case involved a hospital that adopted CNC machining for the fabrication of surgical instruments. Faced with a lengthy procurement process for traditional instruments, the hospital implemented an in-house CNC machining process, allowing for the rapid production of essential tools. As a result, the surgical team experienced a marked decrease in delays, optimizing operating room schedules and improving overall workflow. This shift not only streamlined operations but also ensured that surgeons had access to high-quality, tailored instruments, enhancing surgical efficacy.

In addition, a dental clinic leveraged CNC machining to create custom dental crowns and bridges. The clinic invested in a CNC milling machine that enabled them to fabricate restorations with precision and speed. Patients benefited from shorter wait times and more accurate fits, ultimately leading to higher satisfaction rates. By reducing the manufacturing time of dental devices, the clinic was able to cater to a larger patient base without compromising on quality.

These real-world applications highlight the transformative role of CNC machining in the medical field, illustrating how this technology can enhance both patient outcomes and operational efficiencies across various healthcare settings.

Conclusion: Embracing CNC Machining in Medicine

Throughout this discussion, we have explored the transformative impact of CNC machining on the healthcare sector. This advanced manufacturing technology has demonstrated remarkable capability in creating precision components for medical devices, prosthetics, and surgical instruments, facilitating improved outcomes for patient care. The ability to produce intricate designs with high accuracy not only enhances the functionality of medical equipment but also ensures its reliability and safety in diverse applications.

Moreover, CNC machining allows for the rapid prototyping of new medical devices, fostering innovation by reducing lead times and costs associated with traditional manufacturing methods. As the industry evolves, the integration of materials like biocompatible polymers and advanced alloys through CNC techniques innovates the design of implants and tools, making them more effective and suited to patient needs. Furthermore, automation in CNC machining contributes significantly to consistent quality and productivity while minimizing human error in the manufacturing phase, which is critical in a field where precision is paramount.

As we look to the future, it is essential for medical professionals, manufacturers, and policymakers to embrace CNC machining fully. By investing in this technology, stakeholders can facilitate continuous improvement in healthcare delivery and patient outcomes. The benefits of adopting CNC machining are not limited to cost savings and efficiency; they extend to the very heart of patient care, where innovation can lead to life-saving advancements. As the healthcare landscape continues to evolve, so too must our approaches to manufacturing and technology integration. Thus, embracing CNC machining not only prepares the industry for future challenges but also reinforces a commitment to enhance overall healthcare quality.

**mitolyn**

Mitolyn is a carefully developed, plant-based formula created to help support metabolic efficiency and encourage healthy, lasting weight management.