Introduction to Optical Parts Machining

Optical parts machining is a specialized segment of manufacturing that focuses on creating high-precision components essential for optical applications. This intricate process encompasses a variety of machining techniques aimed at achieving the precise specifications required for numerous optical components, such as lenses, mirrors, prisms, and fiber optic elements. The importance of optical parts machining cannot be overstated, as these components play a critical role in numerous industries, including telecommunications, healthcare, and consumer electronics.

The optical industry encompasses a wide range of applications where precision and clarity are paramount. For instance, in telecommunications, optical components facilitate efficient data transmission through fiber optic cables, enhancing communication systems worldwide. Similarly, in the healthcare sector, optical parts are integral to imaging devices, surgical instruments, and diagnostic equipment, where accuracy directly affects patient outcomes. Consumer electronics also rely heavily on optical components, particularly in devices like cameras, projectors, and displays, where image quality is essential for user experience.

Various materials are utilized in optical parts machining, each selected for specific properties such as refractive index, durability, and weight. Common materials include high-quality glasses, plastics, and ceramics—each offering unique advantages depending on the desired application. The choice of material greatly influences the machining process, requiring specialized techniques to ensure the utmost precision and quality.

In exploring the scope of the optical parts machining industry, it is evident that advancements in technology and innovation continue to drive this field forward. As industries increasingly demand higher precision and efficiency, mastering the techniques associated with optical parts machining becomes a necessity for manufacturers aiming to meet these evolving standards.

Materials Used in Optical Parts Manufacturing

In the realm of optical parts machining, the choice of materials plays a crucial role in achieving the desired optical characteristics. The three primary categories of materials widely used in this field are glass, ceramics, and polymers, each offering unique properties and benefits suited for various applications.

Glass remains one of the most frequently utilized materials in optical components due to its exceptional transparency, optical clarity, and durability. Different types of optical glass, such as crown glass and flint glass, possess varying refractive indices and dispersion properties, making them suitable for specific optical applications. For instance, crown glass is often employed in lenses and prisms because of its low dispersion, while flint glass is used to create high-quality optical elements where higher dispersion is required. The resistance to scratching and environmental conditions further contributes to glass being a preferred choice in many optical devices.

Ceramics, on the other hand, are gaining attention in optical parts machining due to their excellent mechanical strength, thermal stability, and chemical resistance. Advanced ceramic materials can withstand harsh conditions, making them ideal candidates for high-performance applications, such as laser systems and military optics. Their ability to be manufactured precisely allows for intricate designs and shapes, which are often necessary in specialized optical components.

Lastly, polymers are increasingly utilized in optical parts because of their lightweight nature, flexibility, and ease of fabrication. While traditionally viewed as inferior to glass in terms of optical quality, advancements in polymer technology have led to the development of optical-grade polymers that exhibit good transmission and minimal distortion. These materials are often used in applications where weight and form factor are critical, such as in eyewear lenses and certain electronic displays.

Ultimately, proper material selection is vital in optical parts machining to ensure that the components meet the specific performance requirements and optical characteristics needed for their intended applications. The interplay of material properties significantly influences the manufacturing processes and the effectiveness of the final optical product.

Machining Techniques for Optical Parts

When it comes to the manufacturing of optical components, precision is paramount, necessitating the use of specialized machining techniques. Among the most widely utilized methods are grinding, polishing, and laser machining. Each approach has its operational principles along with inherent advantages and limitations, making them suitable for different manufacturing requirements.

Grinding is often the initial step in shaping optical parts. This technique employs an abrasive wheel to remove material from the surface of the workpiece. The principal advantage of grinding is its capability to achieve close tolerances and smooth finishes, which are crucial in optics. However, one limitation is that it may induce thermal stress in certain materials, leading to distortion or surface damage if not carefully managed.

Following grinding, polishing plays a critical role in achieving the required optical clarity. This technique involves the use of fine abrasives or polishing compounds that produce a highly reflective surface. The importance of polishing cannot be understated, as it significantly enhances the optical performance of the components. Nonetheless, polishing can be time-consuming and requires a skilled operator to achieve consistent results without introducing surface defects.

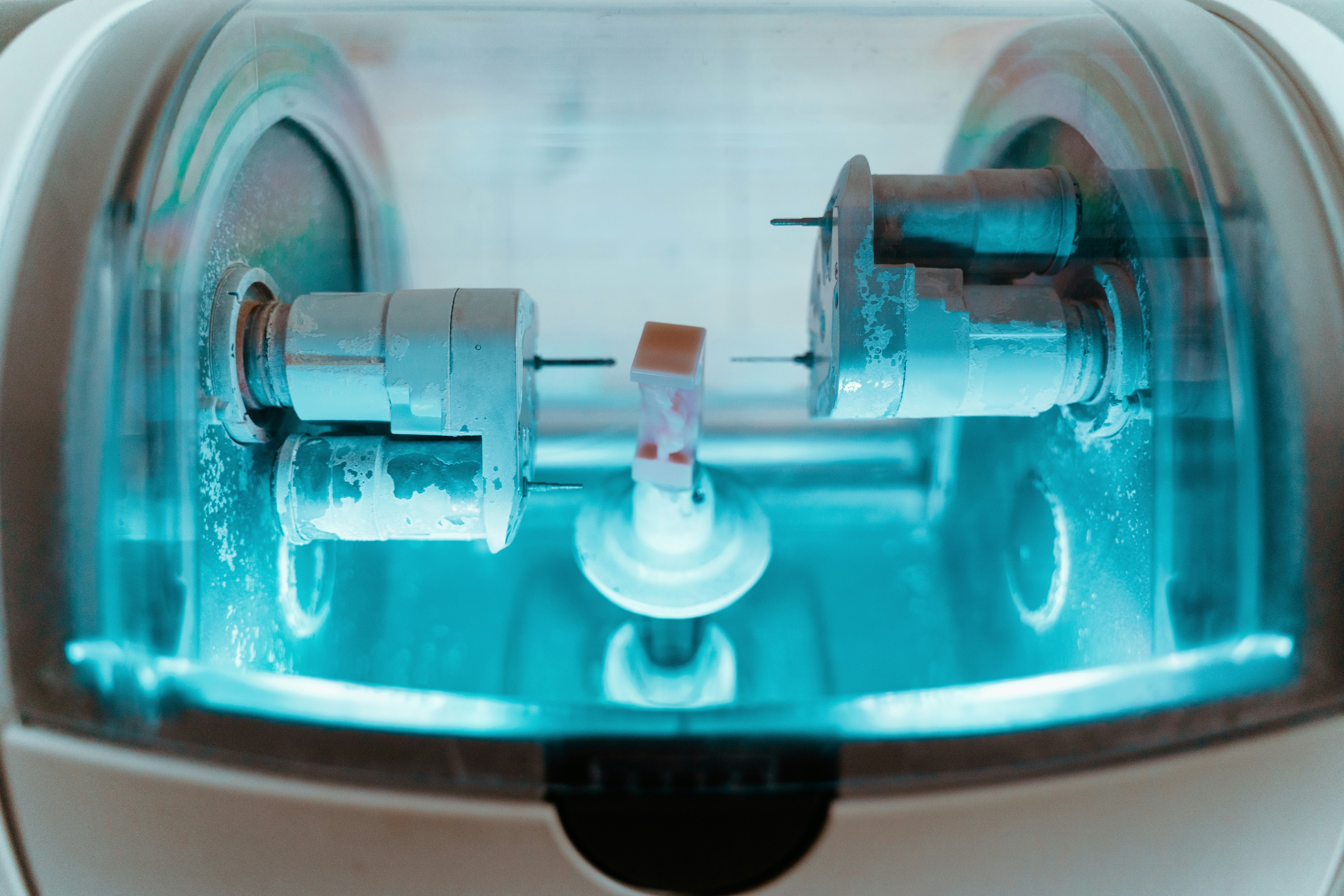

Laser machining has gained popularity in recent years for its ability to efficiently cut and shape optical materials. This method utilizes focused laser beams to precisely remove material, allowing for intricate designs that traditional methods may struggle to produce. The advantages of laser machining include reduced mechanical stress on materials, as well as the ability to automate and integrate into CNC systems, enhancing overall precision and repeatability.

Incorporating CNC technology into these machining techniques is increasingly vital for achieving the utmost precision. Computer Numerical Control allows for precise control over the machining processes, facilitating consistent quality and enabling complex geometries to be manufactured with ease. Ultimately, understanding these various machining techniques is crucial for optimizing the production of optical components in a competitive landscape.

Quality Control and Measurement in Optical Machining

Quality assurance plays a pivotal role in optical machining, significantly impacting the performance and reliability of optical components. Ensuring the precision of these components requires the integration of various quality control methodologies tailored to the unique challenges posed by optical fabrication. Among these methodologies, interferometry stands out as a vital technique used to measure the surface quality and optical performance of parts. This non-destructive approach utilizes the interference of light waves to detect even the most minute surface deviations, providing valuable insights into component accuracy.

Another crucial technique in the verification process is profilometry, which measures the profile of optical surfaces with high-resolution capabilities. By employing either contact or non-contact profilometers, technicians can identify surface irregularities and deviations from design specifications. This information is essential for maintaining the stringent tolerances required in optical machining, where imperfections can lead to reduced optical performance and impacting the overall system functionality.

Visual inspection remains a fundamental quality control method in the fabrication of optical parts. Trained operators typically utilize optical or digital magnification tools to perform detailed assessments of completed components. This method not only helps identify surface defects but also provides insights into the overall aesthetics and readiness of parts for assembly into larger systems.

Furthermore, adherence to measurement standards is vital in ensuring consistency and accuracy across optical machining processes. Utilizing internationally recognized standards, such as those established by the ISO, facilitates a uniform approach to measurement and quality control. The incorporation of advanced measurement technologies, including optical comparators and laser measurement tools, enhances the precision of optical component evaluation, assuring manufacturers and end-users of their reliability and accuracy in various applications.

Common Challenges in Optical Parts Machining

Optical parts machining entails a unique set of challenges that can significantly impact production efficiency and the final quality of the products. One of the foremost issues is maintaining surface quality during machining processes. Optical components require exceptionally smooth surfaces to ensure optimal light transmission and minimal distortion. Any imperfections such as scratches or uneven finishes can severely degrade the performance of the optical devices. This high standard necessitates precision machining techniques and rigorous quality control measures, which can increase production time and costs.

Another significant challenge in machining optical parts is the brittleness of materials commonly used, such as glass and certain ceramics. These materials exhibit a tendency to fracture under mechanical stress. The delicate nature of these materials requires specialized tooling and machining strategies to reduce the risk of chipping or cracking. If not managed properly, material brittleness can lead to high scrap rates, thereby affecting overall productivity and increasing operational expenses.

Tooling wear is yet another concern in optical parts machining. The abrasive nature of optical materials can lead to rapid wear on cutting tools, necessitating frequent replacements and adjustments. This not only contributes to increased costs but also impacts machining precision. To address this challenge, advancements in tooling materials and coatings such as diamond-like carbon (DLC) or ceramic composites have been developed to enhance tool longevity and maintain consistent machining performance.

In addressing these challenges, the optical machining industry has increasingly turned to innovative technologies. Solutions such as ultra-precision machining, computer numerical control (CNC) systems, and adaptive machining strategies have emerged as effective means to overcome these hurdles. By investing in these advanced techniques and technologies, manufacturers can improve the yield and quality of optical parts, thereby enhancing overall production efficiency.

Innovations in Optical Machining Technology

The field of optical parts machining has experienced significant advancements in recent years, driven largely by innovations in technology. These developments have improved efficiency, precision, and the overall quality of optical components, ushering in a new era for manufacturers and end-users alike. One noteworthy trend is the increased integration of automation into optical machining processes. With the adoption of automated systems, manufacturers can achieve higher production rates while minimizing the potential for human error. This automation includes the use of robotic systems for loading and unloading materials, as well as advanced CNC (Computer Numerical Control) machines capable of executing complex geometries with remarkable accuracy.

Another transformative enhancement in optical machining is the incorporation of artificial intelligence (AI) in process optimization. AI technologies facilitate real-time monitoring and adjustments during the machining process, ensuring that any deviations are corrected promptly. Machine learning algorithms analyze large datasets to predict potential issues before they arise, thus improving overall operational efficiency. The use of AI not only enhances output quality but also reduces waste, making the machining process more sustainable and cost-effective.

Moreover, the introduction of new materials and coatings has further refined the capabilities of optical parts machining. Advanced materials, such as ultra-high molecular weight polyethylene (UHMWPE) and specialized composites, offer improved performance characteristics such as higher durability and resistance to wear. Additionally, innovative coatings, including anti-reflective and scratch-resistant options, are increasingly being applied to optical components, enhancing their functionality and longevity. These materials and coatings not only align with performance expectations but also meet the demands of evolving industries, such as telecommunications and aerospace.

In summary, recent innovations in optical machining technology—including automation, AI-driven optimizations, and advanced materials—are significantly reshaping the landscape of optical parts manufacturing, paving the way for enhanced quality and efficiency in the industry.

Applications of Machined Optical Parts

Machined optical parts play a crucial role in various industries, providing essential functionalities across several applications. One of the primary sectors that rely heavily on these components is telecommunications, specifically in fiber optic technology. In this field, precision-machined optical elements enable efficient data transmission through light-based systems, which are fundamental for broadband networks and high-speed internet connectivity. The accuracy of these optical parts is vital for minimizing signal loss and maximizing system performance.

Another significant application can be found in the automotive industry. Advanced optical machining techniques are used to create components such as lenses and sensors, which enhance vehicle safety and functionality. For instance, adaptive headlight systems utilize precision-crafted optical parts to improve visibility under various driving conditions, while sensors employed in advanced driver-assistance systems (ADAS) rely on finely tuned optical components to detect obstacles and maintain safe distance from other vehicles.

In the field of medical devices, the importance of machined optical parts cannot be overstated. Instruments such as microscopes and endoscopes depend on high-quality optical components for accurate diagnostics and minimally invasive procedures. The precision required in these components is a necessity for obtaining clear images of internal structures, assisting healthcare professionals in delivering effective treatment.

Furthermore, consumer electronics, particularly in camera optics, illustrate the widespread use of optical machining. High-resolution cameras found in smartphones and digital devices rely on expertly manufactured optical elements to capture detailed images in various lighting conditions. The competition in this sector drives the continual advancement of machining technologies to enhance image quality and user experience.

Overall, the versatility and significance of machined optical parts are evident across various fields, highlighting their vital contribution to innovation and functionality in modern technology.

Future Trends in Optical Parts Machining

As the demand for precision components in various industries continues to rise, the field of optical parts machining is evolving rapidly. One of the most significant trends is the miniaturization of optical components, which is largely driven by advancements in technology. Smaller, lighter, and more complex designs are necessary for applications in mobile devices, telecommunications, and medical instrumentation. This trend encourages manufacturers to adopt more sophisticated machining techniques that ensure the precision and quality of miniaturized parts.

Another notable development is the integration of smart technologies into the machining process. The implementation of automation and artificial intelligence is transforming the production landscape of optical components. Smart machining systems equipped with sensors and data analytics capabilities enable real-time monitoring and optimization of the manufacturing process. This integration enhances efficiency, reduces error rates, and allows for predictive maintenance, ultimately leading to higher quality assurance in optical parts production.

Sustainability is also becoming a vital consideration in the optical parts machining sector. Manufacturers are increasingly focusing on eco-friendly practices and materials to minimize their environmental impact. The shift towards sustainable manufacturing can include the use of biodegradable materials, energy-efficient machinery, and waste reduction strategies. This trend not only aligns with global sustainability goals but also meets the growing consumer demand for environmentally responsible products.

In summary, the future of optical parts machining is poised for significant transformation, characterized by miniaturization, smart technologies, and sustainable practices. These trends will not only enhance the efficiency and precision of optical components manufacturing but will also redefine the applications across various sectors. As these innovations unfold, it is crucial for manufacturers to adapt and evolve in order to remain competitive in the ever-changing landscape of optical machining.

Conclusion

In the realm of optical parts machining, mastering the various techniques and understanding the associated challenges is paramount. Throughout this blog post, we have explored pivotal methods employed in the production of optical components, highlighting both traditional practices and innovative technologies. These techniques include precision grinding, polishing, and laser machining, each offering distinct advantages and facing specific obstacles. The significance of implementing state-of-the-art machinery and processes cannot be overstated, as they play a crucial role in enhancing precision and efficiency in the manufacturing of optical parts.

Furthermore, we discussed the various challenges faced by manufacturers, such as the need for strict quality control, the complexities of material selection, and the continuous demand for advancements in optical design. The evolution of optical parts machining is driven by an ever-increasing demand for high-quality components in industries ranging from telecommunications to medical devices. This underscores the necessity for manufacturers to remain adaptable, continuously updating their technical skills and equipment to meet the growing market expectations.

As we look toward the future, it becomes evident that ongoing innovations in optical machining technology will play a critical role in shaping the industry. The advent of new materials, advancements in computer-aided design, and improvements in automation all contribute to a more efficient and precise manufacturing process. For manufacturers and consumers alike, it is essential to stay abreast of these developments, as they not only enhance product quality but also optimize production timelines.

Ultimately, the mastery of optical parts machining is not just about understanding current techniques. It is also about fostering a culture of continual learning and adaptation in response to the rapidly evolving technological landscape. Engaging with this dynamic field will be beneficial for all stakeholders involved, from manufacturers to end-users seeking superior optical components.