Introduction to CNC Machining

CNC machining, or Computer Numerical Control machining, represents a transformative approach to manufacturing that has significantly advanced over the years. This method utilizes computer software to control machine tools, enabling high levels of precision and efficiency in producing complex components. Unlike traditional machining methods, which rely heavily on manual operation and often lead to variability in product quality, CNC machining automates the processes involved, thus ensuring greater consistency and accuracy.

The evolution of CNC technology began in the mid-20th century when it emerged as a response to the increasing demand for precision in various industries, particularly in automotive manufacturing. Traditional methods, such as manual milling and lathe work, posed challenges in achieving the fine tolerances and repeatability required for modern automotive parts. CNC machining revolutionized this landscape by integrating computer programming with machinery, allowing for intricate designs to be executed swiftly and with outstanding precision.

At its core, CNC machining works by translating a digital design into a set of numerical values that guide the machine’s movements. This sophisticated process involves various types of machinery, including lathes, mills, and routers, all of which can operate within programmed parameters to deliver exact specifications. The significance of automation in this context cannot be overstated; it not only streamlines production but also reduces human error, lowers labor costs, and accelerates manufacturing timelines. Moreover, the flexibility of CNC machines allows for rapid prototyping and customization, essential attributes in the fast-paced automotive industry where design modifications and iterations are commonplace. As the demand for more efficient and precise automotive parts continues to rise, CNC machining stands at the forefront, driving innovation and excellence in the manufacturing sector.

The Importance of Precision in Automotive Parts

The significance of precision in automotive parts manufacturing cannot be overstated; it directly influences vehicle performance, safety, and durability. In the highly competitive automotive industry, the demand for components that meet stringent specifications is paramount. Precision engineering ensures that every part functions within tolerances that enhance the overall quality of the vehicle, thereby promoting reliability and efficiency.

Automotive components, from engines to steering systems, must operate seamlessly to guarantee optimum performance. For instance, an engine component that is not accurately machined can result in reduced power output or increased fuel consumption. Similarly, precision in brake systems is critical; even slight inaccuracies can have serious implications on a vehicle’s ability to stop in time, posing potential safety risks. The importance of precise machining processes, such as those utilized in CNC machining, becomes evident as they help create components that adhere to exacting specifications.

Moreover, the durability of automotive parts is heavily reliant on precision manufacturing. Parts that are precisely machined are less likely to wear out or fail under pressure, thereby extending the vehicle’s lifespan. High precision reduces the risk of defects, which can lead to costly recalls and repairs, further emphasizing the need for accuracy in production. Furthermore, adherence to rigorous industry standards, such as ISO and SAE, is essential to ensure that automotive parts meet safety regulations and performance benchmarks. These standards define the thresholds for tolerance and quality in automotive manufacturing.

CNC machining has emerged as a pivotal technology in achieving these high standards of precision. By employing advanced techniques and tools, CNC machining allows for the production of complex geometries with exceptional accuracy. This technology is integral to maintaining the delicate balance between performance and safety in automotive parts, solidifying its critical role in the modernization of manufacturing processes.

Common Automotive Parts Manufactured Using CNC Machining

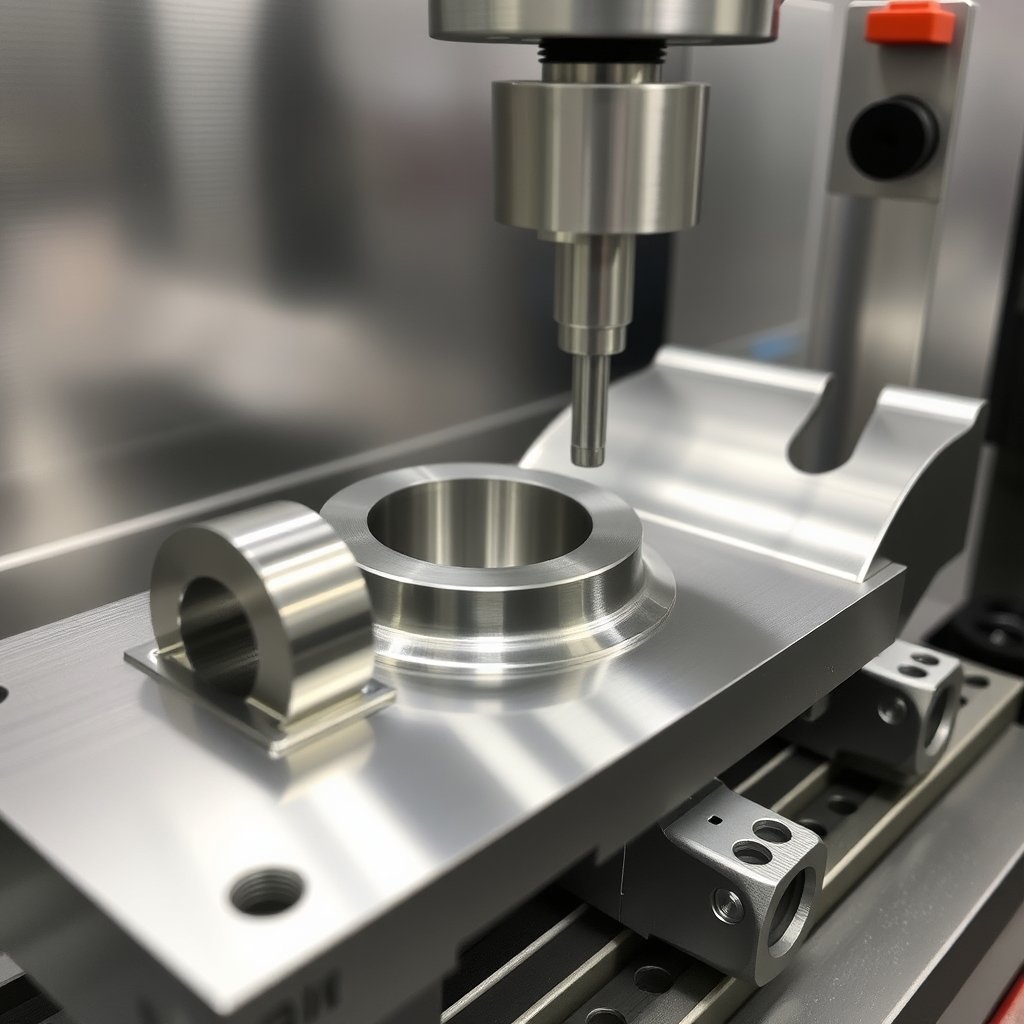

CNC machining plays a vital role in the manufacturing of numerous automotive parts, delivering exceptional precision and reliability. One of the most critical components produced using this technology is engine parts. CNC machining allows for the creation of intricate engine components such as cylinder heads, pistons, and valve covers, which are essential for optimal engine performance. The ability to achieve tight tolerances ensures that these parts fit together seamlessly, resulting in enhanced engine efficiency and reduced emissions.

Another significant category of automotive parts manufactured through CNC machining includes transmission components. Transmission parts, such as gears, shafts, and housings, rely heavily on the accuracy offered by CNC technology. Precision in these components is crucial as it directly affects the vehicle’s shifting quality and overall driveability. CNC machined parts minimize the risk of mechanical failure, ultimately improving the longevity and reliability of the vehicle’s transmission system.

Custom fittings and fixtures also benefit greatly from CNC machining. These include specialized brackets, mounts, and clips that are often required to facilitate the assembly of various automotive systems. By utilizing CNC machining, manufacturers can produce complex geometries tailored to specific vehicle designs. This adaptability not only improves the compatibility of parts but also supports faster assembly processes, reducing labor costs and time-to-market.

Moreover, the capability of CNC machining to work with a variety of materials, including metals, plastics, and composites, expands the range of automotive parts that can be manufactured. This flexibility allows automotive manufacturers to leverage the advantages of lightweight materials without compromising on strength or performance. Consequently, the use of CNC machining in automotive part production fosters innovation and supports advancements in vehicle design and functionality.

The CNC Machining Process Explained

CNC (Computer Numerical Control) machining has become a vital process in the manufacturing of automotive parts, enhancing precision and efficiency. At the core of this process is the initial part design, which utilizes CAD (Computer-Aided Design) software. This software allows engineers and designers to create highly detailed 3D models of the component they wish to manufacture. Through this digital blueprint, any necessary modifications can be made before the actual production begins, ensuring that the design is both functional and manufacturable.

Once the design has been finalized, it undergoes a process called CAM (Computer-Aided Manufacturing), where the digital model is translated into machine-readable code. This code directs the CNC machine on how to move its tools during production. The transition from design to code is crucial, as it dictates the variations of milling, turning, or routing that will be employed based on the specific characteristics of the part.

The next stage involves the physical machining process. For milling, the CNC machine uses rotary cutters to remove material from the workpiece, allowing for the creation of intricate shapes and features. In contrast, turning processes involve spinning the workpiece against a stationary cutting tool to achieve cylindrical components. Another technique, routing, is used primarily for softer materials and involves moving a high-speed rotating tool across the surface to carve out shapes or patterns. Each of these methods contributes significantly to the precision of the automotive parts being produced.

Throughout the machining process, quality assurance measures are implemented to ensure that each part meets specified tolerances and standards. This level of control not only optimizes the manufacturing outcomes but also leads to enhanced performance and safety of automotive components. As the CNC machining process continues to evolve, its integration into automotive manufacturing highlights the importance of precision in achieving quality outcomes.

Materials Used in CNC Machining for Automotive Parts

CNC machining plays a pivotal role in the production of automotive parts, utilizing a variety of materials that cater to the demanding specifications of the industry. One of the most commonly used materials is aluminum, favored for its lightweight properties and excellent machinability. Aluminum components not only help in reducing overall vehicle weight, which enhances fuel efficiency, but they also offer good corrosion resistance, making them ideal for various automotive applications such as engine components and chassis elements.

Steel is another prevalent material in CNC machining for automotive parts, renowned for its strength and durability. Different grades of steel, such as carbon steel and alloy steel, are selected based on the mechanical properties required for specific components. For instance, high-strength steel is often utilized in structural applications where enhanced rigidity and impact resistance are essential. Additionally, the availability of steel at a relatively low cost renders it an economically viable option for mass production in the automotive sector.

Titanium, while more expensive, is also gaining traction in CNC machining for automotive components. Its high strength-to-weight ratio and exceptional resistance to corrosion make it suitable for high-performance applications, such as aerospace-grade automotive parts. Furthermore, titanium is increasingly utilized in parts that experience extreme temperatures or corrosive environments, offering longevity and reliability over time.

In addition to metals, advanced composite materials like carbon fiber and fiberglass are becoming integral in modern automotive design. These materials are increasingly used for their lightweight characteristics without compromising strength. Their application is particularly important in performance vehicles where every ounce counts, providing manufacturers with the ability to produce high-performance parts that meet both traditional strength requirements and weight-saving goals. Ultimately, the choice of material in CNC machining is driven by a careful consideration of performance properties, cost-effectiveness, and the specific needs of automotive applications.

Advantages of Using CNC Machining in Automotive Manufacturing

CNC machining offers a plethora of advantages in the automotive manufacturing sector, fundamentally changing the way components are produced. One of the primary benefits is increased efficiency. CNC machines operate autonomously, allowing for continuous production without the need for constant human oversight. This not only accelerates the manufacturing process but also enables the production of parts at a scale that was previously hard to achieve with traditional methods.

Improved consistency is another critical advantage of CNC machining. Unlike manual machining, where variability can arise from human error, CNC machines are programmed to execute precise movements with exactness. This leads to uniformity in component dimensions, which is crucial for automotive applications where tolerances can be exceedingly tight. Maintaining high consistency also lessens the chance of defects, resulting in higher quality outputs.

Furthermore, CNC machining significantly reduces waste during the manufacturing process. Through techniques such as subtractive manufacturing, material is only removed where necessary, which minimizes excess material usage. This not only is cost-effective but also aligns with sustainable manufacturing practices, as reducing waste translates to less environmental impact.

Another vital benefit is better design flexibility. With CNC technology, automotive engineers can easily produce complex geometries and intricate component designs that would be challenging to achieve with traditional machining. This opens up opportunities for innovation in vehicle design, allowing manufacturers to explore new configurations that enhance performance or aesthetic appeal.

Several companies have successfully integrated CNC technology into their operations. For instance, Ford has leveraged CNC machining in the manufacturing of engine components to enhance both efficiency and precision. Similarly, BMW utilizes CNC technology to create customized vehicle parts tailored to specific customer requirements. These real-world examples highlight the transformative potential of CNC machining in automotive manufacturing.

Challenges and Limitations of CNC Machining in the Automotive Industry

CNC machining has significantly influenced the automotive industry, offering unmatched precision and efficiency. However, several challenges and limitations hinder its widespread adoption and optimization in automotive manufacturing. One of the foremost challenges is the high initial investment costs associated with CNC machines. Acquiring state-of-the-art CNC equipment requires substantial financial resources, which can be a barrier, especially for small and medium-sized enterprises in the automotive sector. These costs also encompass software licenses, tooling, and the infrastructure required to support sophisticated machine operation.

Another critical factor is the necessity for skilled operators. While CNC machines automate many processes, the complexity of operations demands that trained technicians understand both the machinery and the intricacies of automotive part design. These skilled professionals must possess a blend of technical knowledge, creativity, and problem-solving skills, which can sometimes be in short supply. The automotive industry is experiencing a skills gap, and this shortage can impede the seamless integration of CNC machining into production lines.

Furthermore, maintenance plays a crucial role in maintaining production efficiency. CNC machines require regular servicing to ensure optimal performance, which includes inspection of moving parts, software updates, and calibration. Frequent breakdowns or prolonged maintenance schedules can disrupt production cycles and lead to significant downtime. Lastly, not all designs and materials are conducive to CNC machining methods. Intricate geometries or tough materials may limit machinability and require alternative manufacturing techniques. This limitation can restrict the design options for automotive engineers, potentially impacting the innovation of new automotive components.

Future Trends in CNC Machining for Automotive Parts

As the automotive industry continues to evolve, the future of CNC machining is poised for transformative advancements that promise to enhance precision manufacturing. One of the most significant trends is the integration of additive manufacturing, which will allow for the production of complex geometries that traditional subtractive methods cannot achieve. This technique not only minimizes material waste but also enables manufacturers to innovate designs that improve vehicle performance and fuel efficiency.

Additionally, the role of machine learning and artificial intelligence in CNC machining is gaining prominence. These technologies facilitate predictive maintenance, optimize machining processes, and enhance overall production efficiency. By analyzing real-time data from machinery, AI can identify patterns and anomalies, allowing manufacturers to make data-driven decisions that optimize operations. This convergence of AI with CNC machining will enable manufacturers to achieve higher levels of accuracy and reduce the likelihood of defects in automotive parts.

Another notable trend is the increased implementation of the Internet of Things (IoT) within manufacturing environments. IoT technology allows for the seamless connectivity of machinery, enabling real-time monitoring and data sharing across the production floor. This connectivity not only streamlines operations but also enhances collaboration between different departments, leading to faster response times and improved product quality. The ability to collect and analyze data from multiple sources will empower manufacturers to adopt a more proactive approach to quality control and process improvement.

Moreover, the automotive industry is witnessing a shift towards sustainable manufacturing practices. As concerns about environmental impact rise, manufacturers are exploring ways to reduce energy consumption and minimize waste during CNC machining processes. This trend aligns with global sustainability goals and can potentially lead to regulations that shape the future of the automotive supply chain.

In conclusion, the future of CNC machining for automotive parts appears promising, driven by innovations in additive manufacturing, advancements in AI and machine learning, and the integration of IoT. Collectively, these emerging technologies are set to reshape precision manufacturing, enhancing efficiency, quality, and sustainability in the automotive sector.

Conclusion: The Role of CNC Machining in Shaping the Future of Automotive Manufacturing

In the realm of automotive manufacturing, the transition towards more precise, efficient, and scalable production methods has been significantly marked by the advancements in CNC (Computer Numerical Control) machining technology. As we have explored, CNC machining plays a pivotal role in the production of high-quality automotive components, ensuring that manufacturers can meet stringent specifications and maintain high standards of performance. The ability to produce intricate designs with minimal human intervention not only enhances precision but also reduces the likelihood of errors extensively associated with traditional manufacturing processes.

CNC machining has emerged as a cornerstone for manufacturers aiming to achieve both innovation and efficiency. The technology facilitates rapid prototyping and flexibility in design alterations, which are crucial factors in the fast-paced automotive sector. As automotive designs continue to evolve with the introduction of electric vehicles, advanced safety systems, and automated features, the need for sophisticated machining capabilities becomes ever more apparent. The precision offered by CNC machining ensures that complex components are produced accurately, thereby enhancing the overall quality and reliability of automotive products.

Furthermore, the continued advancements in CNC machining technology, including enhanced software capabilities, improved machine tolerances, and the incorporation of artificial intelligence, are expected to revolutionize the automotive manufacturing landscape. These innovations will not only streamline processes but also facilitate a more sustainable approach to production, reducing waste and enhancing resource efficiency. Consequently, it is essential for manufacturers to stay abreast of these developments, as they hold the potential to usher in an era marked by heightened efficiency and innovation, shaping the future of automotive manufacturing significantly.