Understanding CNC Parts: A Comprehensive Guide

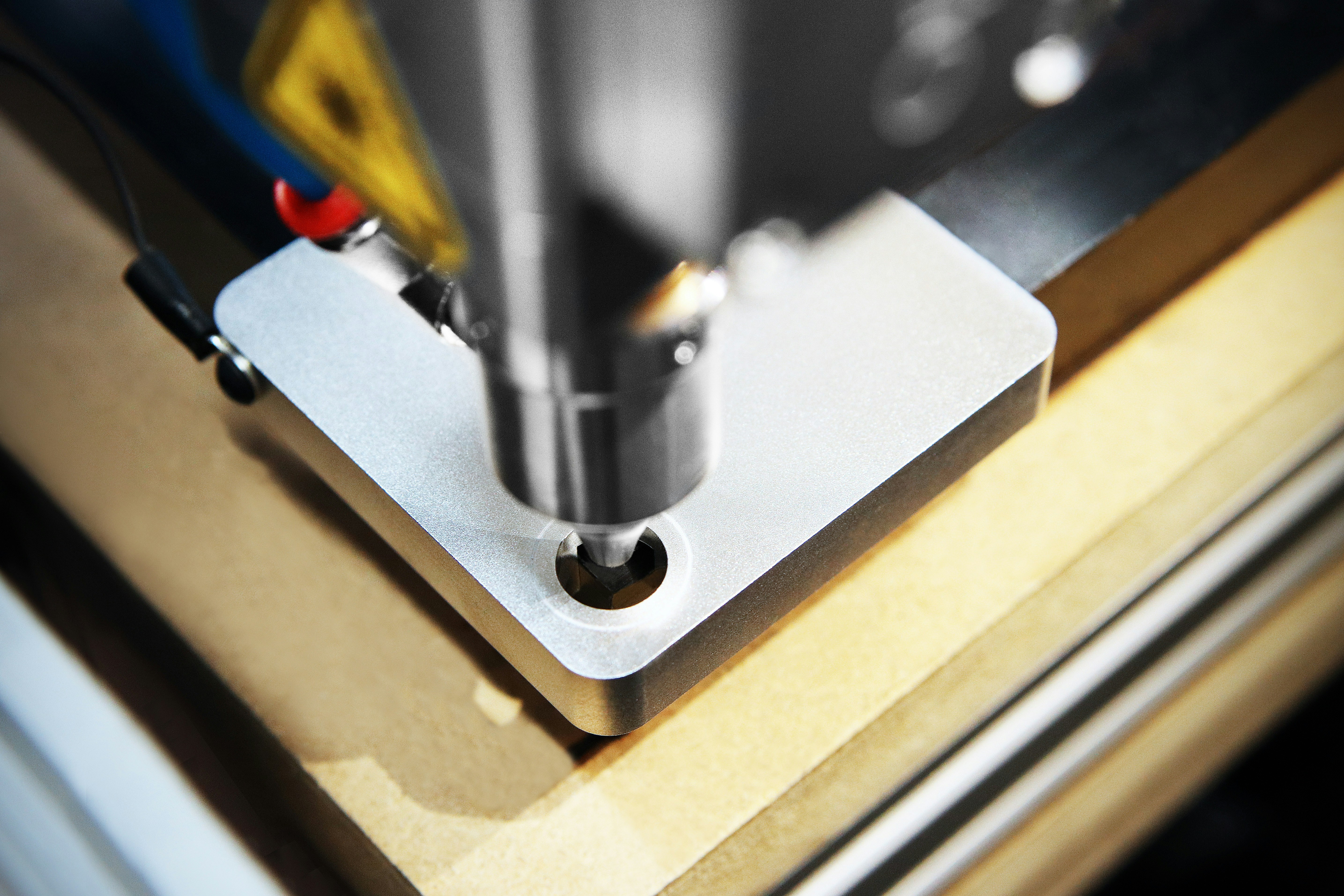

Introduction to CNC Parts CNC, or Computer Numerical Control, represents a significant advancement in modern manufacturing technologies. This method employs computer software to create precise and intricate designs for various components, significantly enhancing production efficiency and accuracy. CNC parts are integral to this process, serving as the building blocks for a wide array of machinery […]