Introduction to CNC Machining

CNC machining, which stands for Computer Numerical Control machining, represents a significant advancement in the manufacturing sector. This innovative method utilizes computer systems to control machine tools, enabling the precise production of parts and components. In contrast to traditional manual machining, CNC machining automates the cutting, drilling, and milling processes, resulting in enhanced accuracy and efficiency. The fundamental principle underlying CNC machining is the use of programmed instructions to dictate the movements and operations of machines, allowing for highly controlled processes.

The incorporation of CNC machines into production environments has revolutionized how parts are manufactured, drastically improving production rates while reducing the likelihood of human error. With the ability to replicate complex designs deep within the manufacturing landscape, CNC machining has expanded the possibilities for various industrial applications. Precision becomes paramount in industries such as aerospace, automotive, and healthcare, where the quality and exactitude of each component can significantly impact overall safety and performance.

Modern CNC machines are equipped with advanced features such as multi-axis capabilities, enabling them to operate on multiple planes simultaneously. This flexibility not only streamlines production but also supports the fabrication of intricate geometries that would otherwise require extensive manual labor. Additionally, CNC machining is characterized by its repeatability; once a design is established, the same product can be manufactured consistently, ensuring uniform quality.

The role of CNC machining in today’s manufacturing processes cannot be understated. As industries continually evolve, the demand for high-quality, precision-engineered parts grows ever stronger. By harnessing the power of automation and computerization, CNC machining ensures that manufacturers can meet contemporary production demands while maximizing efficiency and minimizing waste. The ongoing evolution of this technology promises even further enhancements, making CNC machining an indispensable aspect of modern manufacturing.

Understanding the Operational Principles of CNC Machining

CNC machining, or Computer Numerical Control machining, is a sophisticated manufacturing process employed to shape and create components with high precision. The operational principles of CNC machining can be understood through several key stages: 3D modeling, G-code generation, machine setup, and the actual machining process itself. Each stage plays a crucial role in ensuring accuracy and efficiency in producing intricate parts.

The initial stage, 3D modeling, involves creating a digital representation of the designed part using Computer-Aided Design (CAD) software. This model serves as the blueprint for the component, allowing designers to visualize and manipulate the geometry before proceeding. Advanced CAD programs offer a multitude of tools for modeling, ensuring that every detail is meticulously considered, from dimensions to tolerances.

After the 3D model is finalized, the next step is G-code generation. G-code is a programming language used to instruct CNC machines on how to execute the required tasks. The generated code is derived from the CAD model and contains a series of commands that determine the tool paths, feed rates, and other essential information needed for the machining process. This crucial step bridges the gap between design and manufacturing by translating conceptual ideas into executable instructions.

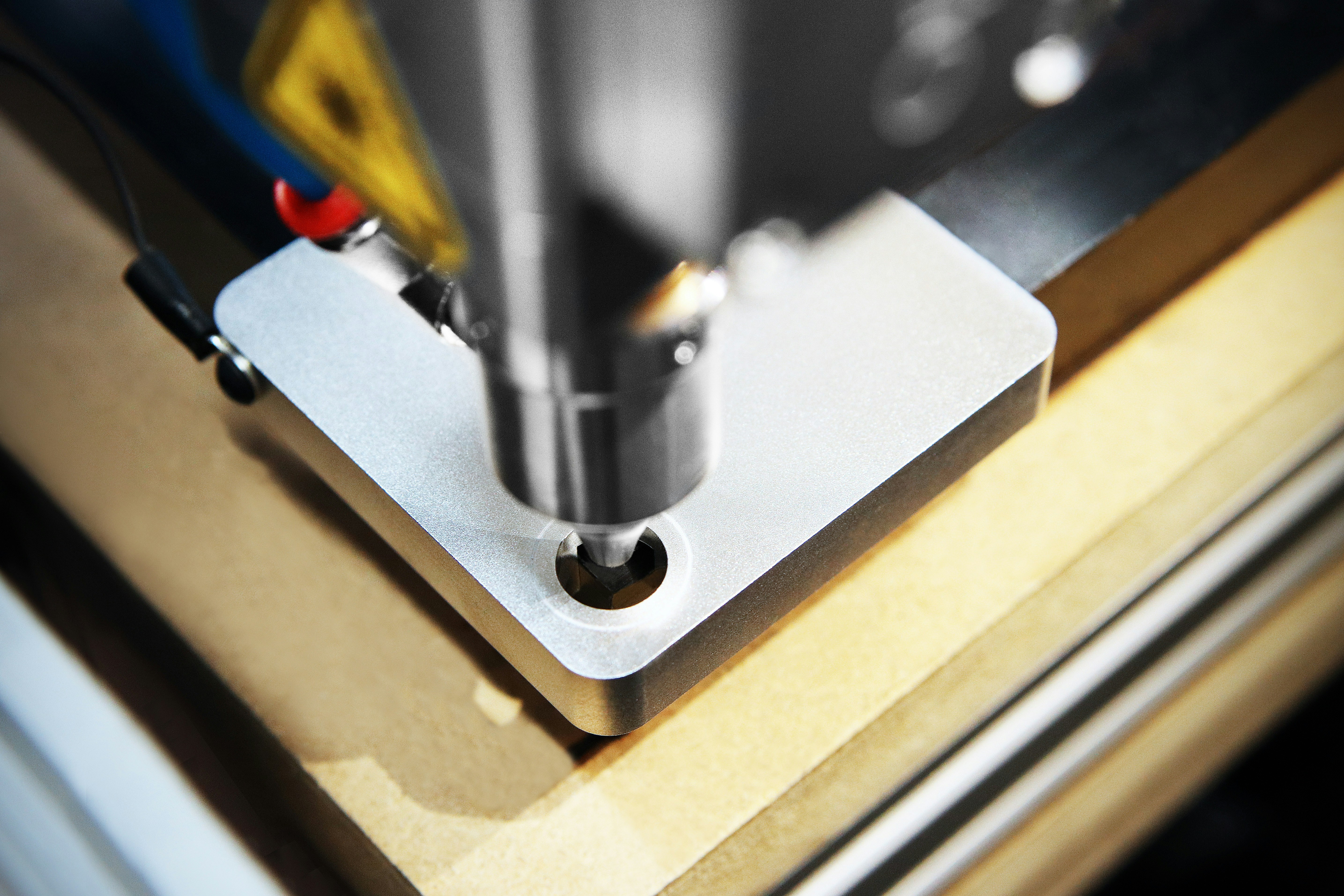

Subsequent to G-code generation, machine setup is undertaken. This involves preparing the CNC machine by securely installing the appropriate tooling, loading the workpiece material, and ensuring that all parameters are configured according to the specifications outlined in the G-code. Proper machine setup is vital for achieving optimal results and minimizing errors during machining.

The final phase of the CNC machining process involves the actual machining operation, where the CNC machine executes the programmed instructions. Utilizing various techniques such as milling, turning, or drilling, the machine removes material to achieve the desired shape and finish. This stage highlights the remarkable precision and efficiency of CNC technology, making it a preferred method in many manufacturing sectors.

Types of CNC Machines

CNC machining encompasses a wide range of machine types, each designed for specific functions and applications within the manufacturing sector. The most common types of CNC machines include CNC mills, lathes, routers, and plasma cutters, each offering unique capabilities that cater to various production needs.

CNC mills are versatile tools that utilize rotary cutters to remove material from a workpiece. These machines can perform complex tasks, such as drilling, boring, and machining flat or contoured surfaces. Typical applications for CNC mills include producing intricate parts for the aerospace, automotive, and medical industries. The precision and efficiency of CNC milling make it an essential component in high-quality production processes.

In contrast, CNC lathes focus on rotationally symmetric components. Utilizing a stationary cutting tool, a CNC lathe shapes the material as it spins on its axis. This method is particularly effective for producing cylindrical parts, such as shafts, bushings, and fittings. CNC lathes offer high precision and consistency, making them invaluable in industries where repetitive production of similar components is necessary.

CNC routers are specialized for cutting softer materials, such as wood, plastics, and composites. These machines utilize a high-speed spindle and interchangeable bits, providing flexibility for various shapes and designs. Applications for CNC routers include the manufacture of cabinetry, signage, and decorative elements in both commercial and residential projects. Their ability to work with larger sheets of material distinguishes them from other CNC machines.

Lastly, CNC plasma cutters are employed primarily for cutting metal. They use a high-velocity jet of ionized gas to melt through metals, producing clean, precise cuts. Plasma cutting is widely used for fabricating parts in the steel and automotive industries. The speed and efficiency of CNC plasma cutters make them an economical choice for large-scale metalwork.

Materials Used in CNC Machining

CNC machining is a versatile manufacturing process that can work with a wide array of materials, each offering unique properties and benefits. The selection of materials plays a crucial role in not only the machining process itself but also in determining the performance and quality of the final product. Among the most commonly used materials in CNC machining are metals, plastics, composites, and wood.

Metals such as aluminum, steel, and titanium are frequently machined due to their strength and durability. Aluminum is particularly favored for its lightweight and corrosion-resistant properties, making it ideal for industries ranging from aerospace to automotive. Steel, known for its hardness and tensile strength, is often used for components requiring high structural integrity. Titanium, while more expensive, offers exceptional strength-to-weight ratios and is widely used in aerospace applications.

Plastics are another category of materials suitable for CNC machining. Thermoplastics like ABS and polypropylene are commonly machined because of their flexibility, lightweight nature, and ease of color customization. Additionally, plastics are resistant to corrosion and can be used in various applications, from consumer goods to electronic parts. The thermal properties of these materials also allow for effective machining at different temperatures.

Composites are becoming increasingly popular in CNC machining as they combine the benefits of different materials. For instance, carbon fiber composites are strong yet lightweight, making them ideal for high-performance applications. Wood is another traditional material used in CNC machining, particularly in cabinetry and furniture-making. Its natural aesthetics and machinability appeal to a wide range of carpentry uses.

Ultimately, the choice of material will significantly impact the machining process and the end product’s overall performance. Engineers and manufacturers must carefully consider the desired properties and requirements of the final components when selecting materials for CNC machining to ensure optimal results.

Benefits of CNC Machining

CNC machining, an innovative manufacturing process, offers numerous advantages over traditional methods. One of the most significant benefits is increased precision. CNC machines are programmed to perform tasks with a level of accuracy that far exceeds manual machining. This precision reduces the likelihood of errors, ensuring that each component meets strict specifications. Such accuracy is critical in industries such as aerospace and medical devices, where tolerances can be exceptionally tight.

Another noteworthy advantage of CNC machining is the reduction in labor costs. Traditional manufacturing often requires a substantial amount of manual labor, which can be expensive and time-consuming. In contrast, CNC machines operate autonomously once programmed, allowing for minimal operator involvement. This automation not only lowers labor expenses but also enables manufacturers to allocate their skilled labor to more strategic tasks, enhancing overall productivity.

CNC machining also leads to lower waste production compared to conventional manufacturing processes. With methods like CNC milling or turning, materials can be utilized more efficiently, resulting in less scrap material. This is particularly beneficial in the context of rising material costs and sustainability efforts, as reduced waste contributes to a more environmentally friendly production cycle.

Furthermore, CNC machining’s ability to produce complex geometries represents a significant advantage. Traditional methods often struggle with intricate designs, which may require numerous setups and approaches. In contrast, CNC machines can execute complex designs in a single operation, minimizing the potential for error and maximizing efficiency. This capability not only enhances the creativity of design engineers but also speeds up the overall manufacturing timeline.

Overall, the advantages of CNC machining, including increased precision, reduced labor costs, lower waste production, and the ability to produce complex geometries, position it as a superior choice for modern manufacturing needs.

CNC Machining Applications

CNC machining plays a pivotal role in various industries due to its precision and efficiency. In the aerospace sector, components such as turbine blades and structural parts are often manufactured using CNC machines. These parts require high tolerance levels and complex geometries, which CNC machining provides. For instance, many companies rely on CNC technology to produce lightweight and durable components that enhance aircraft performance and safety.

In the automotive industry, CNC machining is crucial for creating intricate parts used in engines, transmissions, and even body structures. The ability to machine metals like aluminum and titanium with exceptional accuracy allows manufacturers to produce vehicles that are not only more efficient but also adhere to stringent safety standards. An example includes CNC-machined engine blocks that improve performance while reducing weight compared to traditional manufacturing methods.

The electronics industry also benefits significantly from CNC machining. Components such as housings, connectors, and circuit boards all utilize CNC technology for their production. With the increasing demand for miniaturization, CNC machining enables manufacturers to create small and complex parts that are essential for modern electronics. For example, precision machined parts are critical in smartphones and consumer electronics, where size and function must coexist without compromising performance.

In the medical field, CNC machining produces components for devices such as surgical instruments, prosthetics, and implants. The precision required in these applications is paramount, as they directly impact the effectiveness and safety of medical procedures. Utilizing CNC technology allows manufacturers to create custom solutions tailored to the needs of patients and medical professionals alike, ultimately advancing healthcare outcomes.

Overall, the diverse applications of CNC machining across these industries underscore its importance and versatility as a manufacturing process. Each sector leverages the capabilities of CNC technology to achieve high-quality, reliable components that drive innovation and efficiency.

Challenges in CNC Machining

CNC machining, a pivotal technology in modern manufacturing, presents various challenges that can affect efficiency and productivity. One of the primary concerns is the high initial cost associated with purchasing CNC machines and the software required for operation. These machines, particularly advanced models, often require substantial financial investment. This upfront expense can be a barrier for small to medium-sized enterprises, which may struggle to justify the capital outlay. However, leasing options and financing arrangements can provide an alternative that may alleviate some of these concerns.

Another significant challenge in CNC machining is the necessity for skilled operators. Operating CNC machinery demands a thorough understanding of programming, tooling, and the machining process itself. The complexity of modern CNC systems, incorporating computer-aided design (CAD) and computer-aided manufacturing (CAM) software, necessitates a workforce skilled in these technologies. To address this, companies may invest in training programs that enable workers to develop the required skills, fostering a competent workforce capable of optimizing machine capabilities.

Moreover, maintenance is a critical concern within the realm of CNC machining. As machines are subjected to prolonged use, wear and tear can lead to malfunctions that disrupt production schedules. Regular maintenance and inspections are essential to ensure machines operate efficiently and to prolong their lifespan. Implementing a structured maintenance schedule can minimize unexpected downtimes. Additionally, predictive maintenance technologies utilizing IoT and AI can further mitigate the impact of equipment failures by allowing manufacturers to identify issues before they escalate.

In summary, while CNC machining provides numerous advantages in manufacturing, the challenges of high initial costs, the need for skilled operators, and maintenance requirements must be addressed strategically. By leveraging training initiatives and innovative maintenance solutions, manufacturers can optimize their CNC operations and mitigate these challenges effectively.

The Future of CNC Machining

The landscape of CNC machining is undergoing significant transformation due to emerging trends and technology advancements. Innovative methodologies are reshaping the industry, improving efficiency and precision in production. Among these advancements, the integration of Artificial Intelligence (AI) stands out as a game-changer. AI capabilities, including machine learning algorithms, facilitate predictive maintenance which enhances equipment reliability and minimizes downtime. This ensures that CNC machines can operate at optimal levels, ultimately boosting productivity.

Another important trend is the Internet of Things (IoT), which allows for seamless connectivity between machines. By embedding smart sensors in CNC equipment, manufacturers can gain real-time data analytics that guide decision-making processes. Such intelligence can optimize workflows, enhance quality control, and support remote monitoring functionalities. As a result, companies can respond more swiftly to production demands and effectively manage resources.

Additive manufacturing techniques, often associated with 3D printing, are also making significant inroads into the CNC machining sphere. These techniques enable the production of complex geometries that traditional subtractive machining methods might struggle with. By combining additive and subtractive processes, manufacturers can achieve enhanced flexibility and sophistication in their designs, paving the way for customized solutions across various industries, from aerospace to healthcare.

Furthermore, sustainability is emerging as a pivotal theme in the future of CNC machining. The focus on eco-friendly practices has prompted the adoption of advanced materials and energy-efficient processes. By minimizing waste and optimizing resource consumption, businesses can not only reduce their environmental impact but also align with the growing demand for socially responsible manufacturing.

Overall, the future of CNC machining is poised for remarkable developments. The integration of AI, IoT, and additive manufacturing combined with a commitment to sustainability will undeniably redefine production methods, creating opportunities for enhanced efficiency and customization in the industry.

Getting Started with CNC Machining

CNC machining is an advanced manufacturing process that utilizes computer-controlled tools to create precise and complex components. For individuals looking to embark on a journey into CNC machining, it is essential to understand various foundational elements that can facilitate entry into the field. The first step involves selecting suitable machines. Beginners may consider starting with a desktop CNC mill or a CNC router, both of which are cost-effective and user-friendly. As familiarity with the technology grows, one may look into more advanced options such as CNC lathes or multi-axis machines.

Another critical aspect to explore is the availability of training resources. Many educational institutions and online platforms offer courses tailored to CNC machining. These training programs typically cover essential topics such as machine operation, programming, and maintenance. Online resources, including video tutorials and forums, can also provide valuable insights and support. Aspiring CNC machinists should take advantage of industry-standard software like CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing). Proficiency in these software applications is crucial, as they facilitate the translation of designs into machine instructions.

Finally, as beginners refine their skills, it is advisable to investigate job opportunities within the CNC machining industry. An array of positions is available, ranging from machine operators to CNC programmers. Networking with professionals in the field can provide insight into the industry’s demands and lead to potential job placements. Local manufacturing companies, fabrication shops, and specialized CNC firms are key places to explore job openings. By following these guidelines and actively engaging with both training and job-searching avenues, one can efficiently transition into the dynamic world of CNC machining.