Introduction to Optical Parts Machining

Optical parts machining refers to the specialized manufacturing process used to create precision components that are essential for a variety of optical devices, including lenses, mirrors, and prisms. The accuracy and quality of these components are crucial for their performance in numerous applications. As industries such as telecommunications, aerospace, and healthcare continue to advance, the demand for high-quality optical parts has escalated, underscoring the importance of this intricate machining process.

In telecommunications, optical components facilitate the transmission of information over long distances via fiber optic cables. Precision machined lenses and filters ensure the integrity of signals, which is vital for high-speed data transfer and communication. Similarly, in the aerospace sector, optical systems are integrated into navigation and surveillance equipment, where the reliability of optical parts directly impacts safety and operational efficiency.

The healthcare industry has also seen a significant surge in the utilization of optical parts. Optical devices such as endoscopes and microscopes rely on meticulously machined components to provide precise imaging capabilities, thereby enhancing diagnostic and treatment procedures. High-quality optical parts ensure that these devices function optimally, leading to better patient outcomes.

The process of optical parts machining involves an array of techniques and technologies that enable the production of components with exceptional dimensional accuracy and surface finish. Techniques such as grinding, polishing, and laser machining are commonly employed to meet the stringent specifications required in this field. Furthermore, advancements in software and automation are continuously improving the efficiency and precision of the machining processes.

As the need for advanced optical systems grows, it becomes increasingly essential to understand the intricacies of optical parts machining. This understanding not only fosters innovation in product design but also highlights the vital role that precision machining plays in various industries, contributing significantly to technological progress and the enhancement of everyday life.

Key Materials Used in Optical Machining

Optical machining relies on a diverse array of materials, each chosen for its unique properties that enhance optical performance. The most commonly used materials in this domain include glass, ceramics, and various plastics, each offering distinct advantages and presenting specific machining challenges.

Glass is one of the most prevalent materials in optical parts machining due to its excellent clarity and ability to transmit light effectively. Different types of optical glass, such as crown and flint glass, possess unique refractive indices that allow for precise manipulation of light paths. However, the brittleness of glass poses challenges during machining processes, necessitating specialized techniques to prevent cracking and chipping. Furthermore, the need for high precision in surface finishing to minimize optical aberrations underscores the importance of advanced machining methods in glass fabrication.

Ceramics have gained prominence in optical machining, particularly in creating robust components that require increased resistance to thermal and mechanical stresses. Materials such as alumina and zirconia are often utilized, as they can also exhibit excellent optical properties. The machining of ceramics, however, can be quite demanding owing to their hardness and brittleness. Techniques such as diamond grinding and precision laser machining are commonly employed to achieve the required geometrical accuracy while minimizing damage to the material.

Plastics serve as versatile alternatives in optical machining applications, particularly in instances where weight reduction and impact resistance are essential. Materials such as polycarbonate and acrylic offer transparency comparable to glass while being lighter and more impact-resistant. However, the thermal sensitivity and lower rigidity of plastics necessitate careful handling and processing to maintain dimensional accuracy and surface quality.

Each of these materials presents unique properties and challenges in optical parts machining, highlighting the importance of understanding material characteristics to ensure the successful manufacture of high-quality optical components.

Machining Techniques for Optical Components

The fabrication of optical components requires precise machining techniques to ensure the desired levels of performance and quality. Among the primary techniques employed in optical parts machining are grinding, polishing, and micro-machining. Each method brings its own set of processes and advantages tailored to meet specific optical needs.

Grinding is often the first step in shaping optical parts, particularly glass or plastic substrates. This process utilizes bonded abrasives to remove material from the workpiece, achieving close dimensional tolerances. The efficiency of grinding allows for the rapid production of various shapes, making it suitable for components such as lenses and prisms. However, it is essential that the selection of the grinding wheel is compatible with the material being processed to avoid damage and ensure an acceptable surface finish.

Following grinding, polishing is employed to enhance the surface quality of optical components. This technique uses finer abrasives or polishing compounds to eliminate surface irregularities imparted during grinding. Polishing not only imparts a smooth finish but also minimizes surface scatter, thus optimizing light transmission characteristics. Understanding the material properties and selecting the appropriate polishing methods, including fixed-abrasive or loose-abrasive techniques, is crucial for achieving high-quality optical components.

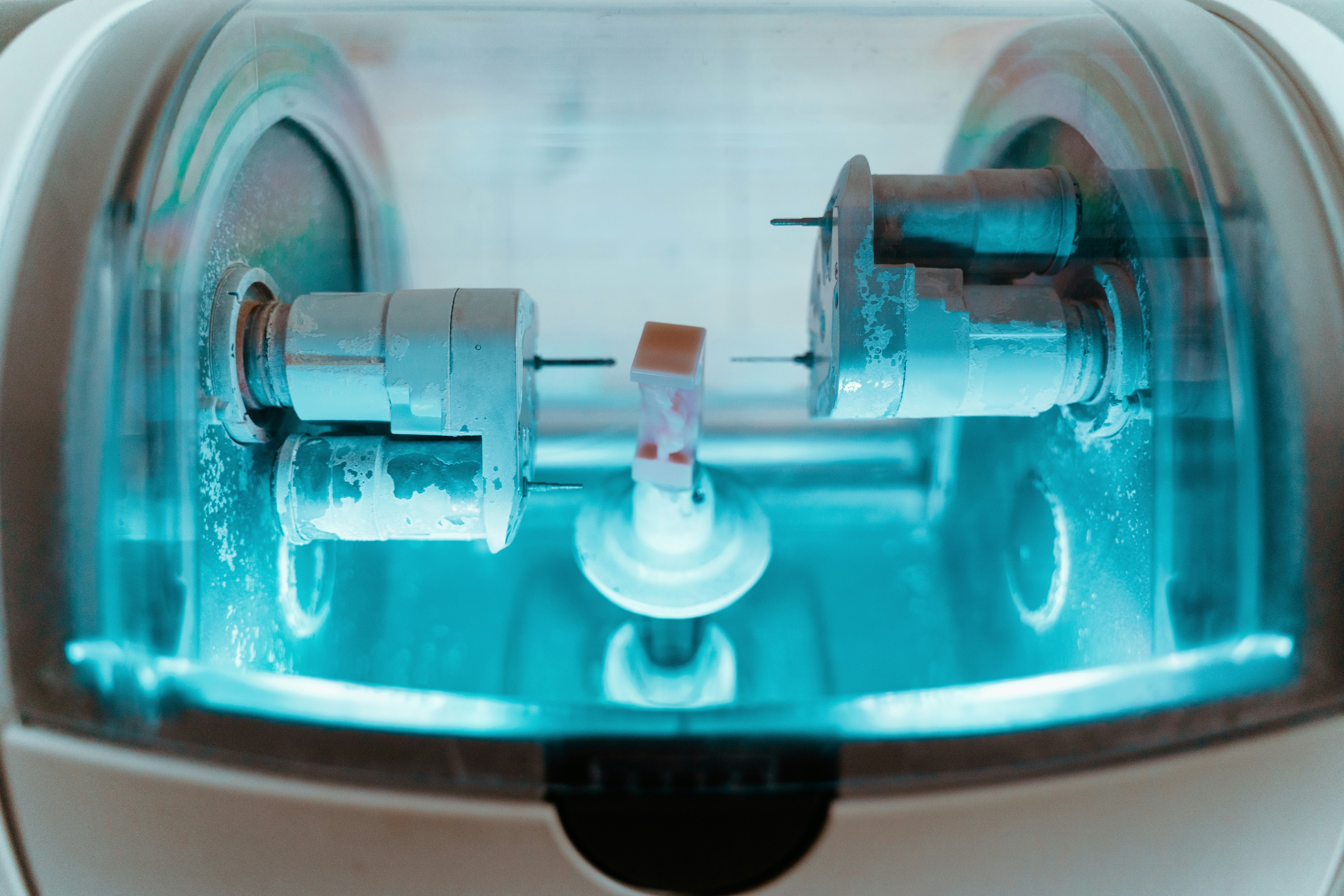

Micro-machining, another significant technique in optical parts fabrication, involves the use of advanced tools such as lasers and electron beams. This technique allows for the creation of intricate patterns and features with high precision, ideal for applications such as micro-lenses and diffractive optical elements. The main advantage of micro-machining is its ability to produce complex geometries that are often not feasible with conventional machining methods.

In the fabrication of optical components, achieving fine surface finishes and tolerances is paramount. These factors significantly impact the performance of optical systems. Therefore, understanding the intricacies of various machining techniques is essential in the optical parts machining industry.

The Role of CAD/CAM in Optical Parts Machining

In the field of optical parts machining, the integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies plays a pivotal role in advancing precision and efficiency in the production of complex optical components. Over the years, the evolution of CAD/CAM systems has transformed the manufacturing landscape, allowing engineers and manufacturers to design intricate geometries that were previously unachievable with traditional machining methods.

CAD software empowers designers to create highly detailed 2D and 3D models of optical parts, such as lenses, mirrors, and prisms, with remarkable accuracy. These models facilitate simulations and virtual testing, enabling design optimization before actual production begins. Modern CAD systems are equipped with advanced features that allow for the manipulation of complex surfaces and the integration of specifications that directly pertain to optical performance. As a result, manufacturers can realize designs that enhance light transmission, reduce aberrations, and improve overall functionality.

Once a design is finalized, CAM software takes over to guide the manufacturing process. It converts the digital models from CAD into machine instructions tailored for precision machining equipment. This connection between design and manufacturing diminishes the chances of error, ensuring that the final product closely matches the original specifications. Additionally, CAM systems enable the automation of machining processes, which increases throughput and reduces production time. The ability to produce parts with intricate details efficiently is particularly crucial in the optical industry, where even minor imperfections can impact overall performance.

The synergy of CAD and CAM also facilitates iterative design processes through rapid prototyping. This capability allows manufacturers to test and refine designs in shorter time frames, ensuring quicker adaptation to customer needs and market demands. Overall, the adoption of CAD/CAM technologies is indispensable in modern optical parts machining, as these tools empower manufacturers to achieve higher standards of precision, efficiency, and complexity in their products.

Quality Control and Testing in Optical Machining

Quality control and testing play a crucial role in the optical machining industry, ensuring that manufactured optical parts meet the rigorous standards required for optimal performance in various applications. Given the sensitive nature of optical components, such as lenses and mirrors, the precision in their fabrication must be measured with utmost care. To achieve this, a range of inspection techniques are employed, including interferometry and profilometry, which provide insights into the surface quality and dimensional accuracy of optical parts.

Interferometry, for instance, is a highly precise optical technique used to measure the surface flatness and quality of optical components. By utilizing the wave nature of light, interferometers can detect minute deviations in surface geometry that may affect optical performance. This method is particularly valuable for components that require a high degree of surface smoothness, such as optical mirrors used in telescopes or high-performance lasers. Through careful analysis of the interference patterns produced, manufacturers can identify any irregularities and make necessary adjustments in the machining process.

Profilometry is another essential technique in quality assurance, focusing on the measurement of the surface profile of optical parts. This method provides detailed information about surface roughness, which is critical for applications where light transmission and reflection are pivotal. Optical profilometers employ various technologies, including contact and non-contact methods, to gather comprehensive data on the surface features of machined parts. This information allows engineers to ensure that the components not only meet aesthetic standards but also perform reliably in optical systems.

Quality assurance in optical machining does not solely rely on testing practices; it also encompasses the implementation of robust manufacturing processes, traceability, and adherence to industry standards. By maintaining stringent quality control protocols, manufacturers in the optical machining sector ensure that every component functions as intended, ultimately contributing to the overall success and reliability of optical systems across various industries.

Challenges in Optical Parts Machining

Optical parts machining presents several challenges that professionals in the field must navigate to achieve optimal results. One of the primary hurdles is the demand for high surface accuracy. Optical components, such as lenses and mirrors, require precision in their dimensions and surface finishes to function correctly. Achieving tolerances within microns is essential, and any discrepancies can lead to optical aberrations, negatively affecting performance. To address this, advanced machining techniques and precise calibration of equipment are necessary, allowing machinists to meet stringent requirements.

Another challenge encountered during the optical machining process is managing thermal effects. Machining processes often generate heat, which can alter the dimensions and properties of optical materials, leading to warping or distortion. This thermal expansion can compromise the integrity of the finished product. Implementing effective cooling methods, such as using coolant fluids or optimizing machining speeds, can mitigate these thermal effects and maintain the dimensional accuracy of optical parts.

Moreover, handling the limitations of material properties poses a significant challenge. Optical materials, such as glass and certain plastics, often have unique characteristics that can complicate machining. For instance, brittle materials may chip or crack under stress, while softer materials might deform. Understanding the specific properties of each material allows machinists to select appropriate tools and techniques tailored to the workload, thus enhancing machining outcomes. Utilizing advanced technology, including Computer Numerical Control (CNC) machines, can also facilitate greater control over the machining process, contributing to more predictable results.

Incorporating best practices, such as thorough pre-machining inspections and process optimizations, can help in addressing these challenges effectively. As technology continues to evolve, the optical machining industry must adapt to these complexities, ensuring precision and quality in every project.

Emerging Trends in Optical Machining Technology

The landscape of optical parts machining is continually evolving, driven by recent advancements in technology. One significant trend reshaping this field is the integration of automation. Automated systems are becoming increasingly sophisticated, allowing for enhanced precision and increased efficiency in the machining process. This shift not only reduces production times but also minimizes human error, leading to higher consistency and quality in the final products. Robotics and machine learning algorithms are now being employed to optimize workflows, making it possible to handle complex tasks that would have been labor-intensive or impractical in the past.

Another noteworthy advancement in optical machining technology is the adoption of laser machining techniques. Laser technology has revolutionized how optical components are crafted, offering non-contact processing methods that yield superior surface finishes and intricate designs. The ability to precisely control laser parameters allows manufacturers to tailor the machining processes to suit various materials, including glass, ceramics, and crystals. This adaptability makes laser machining a preferred choice for producing optical parts with demanding specifications.

Furthermore, the rise of additive manufacturing techniques is making a significant impact on the optical parts industry. Known for its capacity to create complex geometries, 3D printing is being utilized to fabricate optical components that were once considered too challenging to produce through traditional methods. This trend not only facilitates rapid prototyping but also paves the way for innovative designs that enhance functionality and performance. As these technologies advance further, they have the potential to transform optical parts machining, enabling manufacturers to meet the rising demand for customized and high-performance components.

Industry Applications of Optical Parts

Optical parts are crucial components in a variety of industries, significantly enhancing the performance and functionality of numerous applications. In scientific instrumentation, optical components such as lenses, mirrors, and prisms are fundamental in devices like microscopes and spectrometers. These components enable precise light manipulation, which is vital for accurate measurements and analysis in fields such as biology, chemistry, and physics. For instance, in a high-resolution microscope, the quality of optical parts directly influences the clarity and detail of the images produced, allowing researchers to make more informed conclusions.

In the realm of consumer electronics, optical parts are integral to devices such as cameras and smartphones. High-quality lenses are designed to ensure optimal image quality and clarity, which are critical features for users. A case in point is the evolution of digital cameras that employ advanced optical designs to achieve better focus and depth of field, significantly enhancing the user experience. Similarly, augmented reality systems rely heavily on optical components to create immersive environments, where precision in optics is pivotal for realism and user satisfaction.

Moreover, military optics represent another significant area where the importance of optical parts cannot be overstated. Applications such as night vision goggles and targeting systems require optical components that provide not only durability but also exceptional clarity and light transmission under various conditions. The integration of advanced anti-reflective coatings and high-index glass materials can drastically improve visual performance, thus impacting mission success rates. For example, a well-optimized scope can aid snipers by providing enhanced target acquisition capabilities, demonstrating the critical role optical parts play in defense technologies.

As seen in these diverse applications, the meticulous machining of optical components directly influences product performance. Therefore, understanding the intricacies involved in manufacturing these parts is essential for businesses aiming to improve their technological capabilities across various sectors.

Future Prospects for Optical Parts Machining

The future of optical parts machining appears promising, with several potential growth areas emerging in response to advancements in technology and the changing needs of the optical manufacturing sector. As industries increasingly demand precision components for various applications, including telecommunications, healthcare, and consumer electronics, the importance of refining optical machining processes has become paramount. This growing demand indicates a clear trajectory of expansion for the optical parts machining industry.

Technological advancements are at the forefront of this evolution. The integration of automation, artificial intelligence, and machine learning into manufacturing processes is expected to enhance efficiency and accuracy in the machining of optical components. These technologies enable precision in production that was not possible with traditional methods, thus reducing waste and increasing overall output. Furthermore, the development of advanced materials is paving the way for optical parts that could surpass the limitations of current materials, leading to enhanced optical performance and durability.

Moreover, ongoing research and development initiatives are vital for fostering innovation within this field. Collaborations between academic institutions, industry leaders, and government bodies are fueling exploration into new machining techniques, which can further optimize the optical manufacturing process. As researchers identify novel methodologies, the industry can anticipate the emergence of groundbreaking products that meet the ever-evolving marketplace demands.

As we look to the future, it is clear that adapting to the latest technological trends while addressing the unique challenges of optical parts machining will be essential. By embracing emerging technologies and investing in R&D, the optical machining industry is likely to unlock new opportunities, ensuring sustainable growth and innovation in the years ahead. The evolving landscape promises to challenge current paradigms, pushing the boundaries of what is achievable in optical manufacturing.