Introduction to CNC Machining in Healthcare

CNC (Computer Numerical Control) machining has significantly transformed various industries, with its impact in the medical sector being particularly noteworthy. This advanced manufacturing process employs computer systems to control machining tools, enabling the production of highly precise components that are essential for various medical applications. CNC technology is pivotal in ensuring that medical devices and equipment meet strict regulatory standards while also maintaining the required level of accuracy and quality.

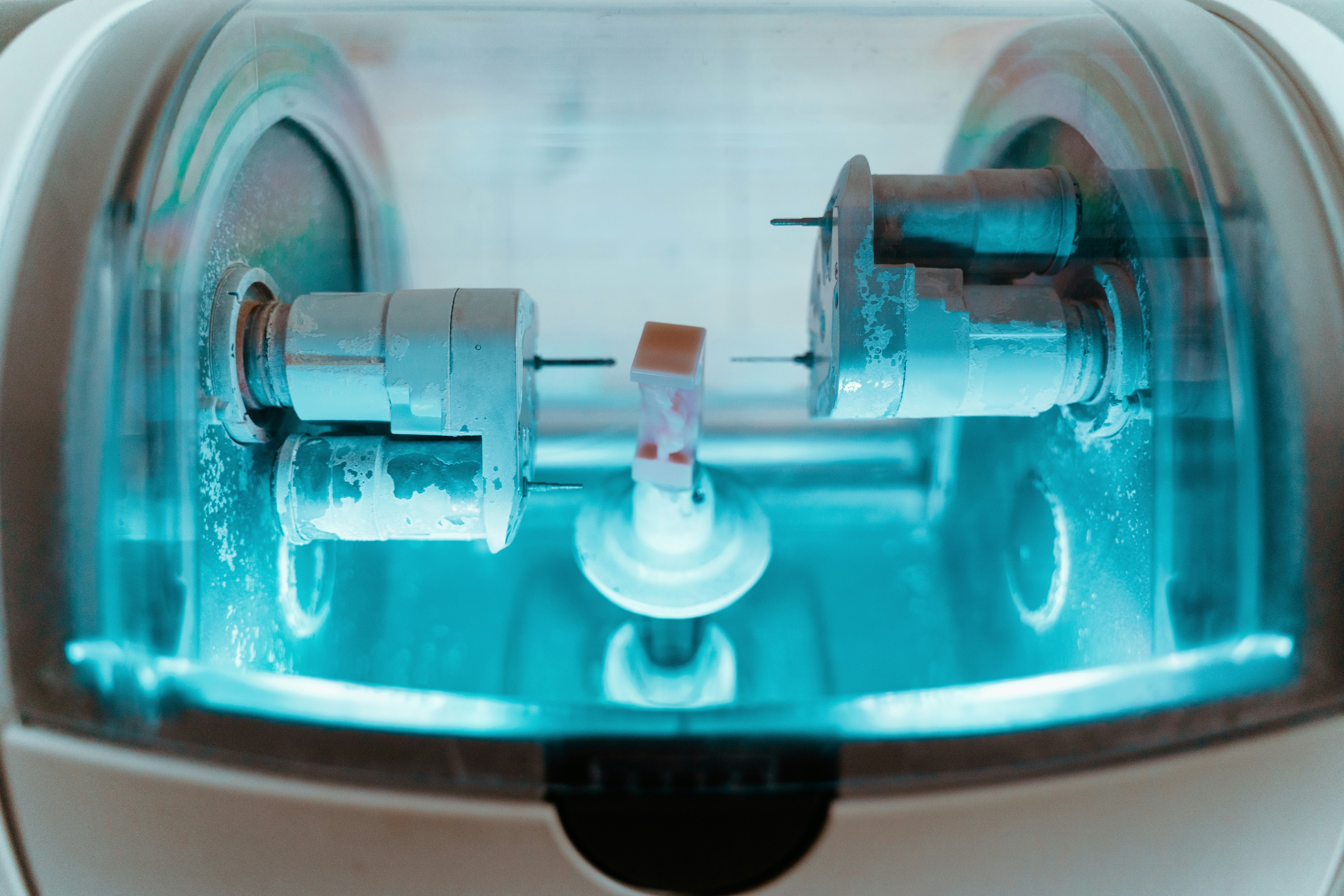

The significance of CNC machining in the medical industry primarily lies in its ability to fabricate complex geometries and intricate designs that are often required in healthcare applications. For example, surgical instruments demand a high degree of precision to ensure successful outcomes during procedures. CNC machining allows for the production of these tools with exceptional accuracy, minimizing the potential for error.

Another key benefit of using CNC technologies in medical applications is consistency. Equipment produced through CNC machining offers uniformity across batches, which is vital in healthcare settings where the reliability of medical devices can directly affect patient safety. Furthermore, the efficiency of CNC processes allows manufacturers to cater to growing demands without compromising quality, thereby enhancing overall productivity.

Applications of CNC machining in the medical field are diverse, ranging from the creation of surgical instruments to implantable devices. For instance, components made via this technology include orthopedic implants, dental fixtures, and even intricate devices like pacemakers. These examples underscore the essential role that precision CNC components play in modern healthcare, ultimately contributing to advancements in medical technology and improvements in patient care.

Key Benefits of Precision CNC Components in Medical Applications

The medical industry heavily relies on precision and accuracy, particularly in the production of medical devices and components. One significant advantage of utilizing precision CNC components in medical applications is their exceptional accuracy and reduced tolerances. These capabilities ensure that every component meets rigorous specifications, which are critical for device reliability and patient safety. For example, components used in surgical instruments or implantable devices must adhere to extremely tight tolerances to function effectively and safely within the human body.

In addition to enhancing accuracy, precision CNC components are instrumental in streamlining production processes. Traditional manufacturing methods may involve several steps that can introduce variability; however, CNC machining offers a more controlled approach. This automation not only reduces the risk of human error but also accelerates production timelines, enabling manufacturers to meet the growing demand for medical devices. Furthermore, the high degree of repeatability provided by CNC machining contributes to maintaining stringent quality standards, ensuring that each batch of products is consistent and reliable.

Another benefit of precision CNC components is their potential for customization. The medical field is diverse, with varying patient needs and customized treatment plans becoming increasingly common. CNC machining allows medical device manufacturers to produce tailored components quickly, accommodating specific requirements without considerable lead times. For instance, custom implants can be produced for individual patients, enhancing overall outcomes.

Case studies have demonstrated the effectiveness of precision CNC components in the medical industry. One notable instance involves a manufacturer that successfully reduced lead times by 50% through the integration of CNC machining in their production process. Testimonials from professionals within the medical field consistently highlight the importance of accuracy and customization, further solidifying the role of precision CNC components as an invaluable asset in medical applications.

Materials Used in CNC Machining for Medical Devices

CNC machining plays a pivotal role in the manufacture of precision components for the medical industry, and the choice of materials is critical to ensuring the functionality and safety of these devices. Among the most widely utilized materials are titanium, stainless steel, and various polymers, all of which possess properties tailored to meet rigorous medical standards.

Titanium is particularly favored for its outstanding biocompatibility, strength-to-weight ratio, and excellent corrosion resistance. It is commonly used in implants and surgical instruments due to its ability to withstand bodily environments without triggering adverse reactions. Additionally, titanium’s capacity to be anodized allows for enhanced surface properties, which can be further optimized through CNC machining techniques.

Stainless steel is another essential material in the medical sector. Known for its durability and resistance to corrosion, it is widely used in tools and devices that require sterilization. Specific grades of stainless steel, such as 316L, are particularly sought after for their low carbon content and biocompatibility. The precision achieved through CNC machining ensures that stainless steel components meet the dimensional and tolerancing requirements vital for operational efficacy in medical applications.

In contrast, polymers have seen increasing popularity due to their versatility and lightweight nature. Materials such as polycarbonate and PEEK (polyether ether ketone) are frequently employed in medical devices where flexibility, biocompatibility, and chemical resistance are essential. These materials allow for innovative designs that can accommodate various medical functions while being cost-effective to produce. CNC machining advances have also paved the way for the production of complex geometries in polymer-based components.

Despite these beneficial properties, selecting appropriate materials for medical applications poses challenges. Factors such as biocompatibility testing, regulatory compliance, and material sourcing can complicate the decision-making process. However, innovations in material science are continuously evolving, leading to improved solutions that enhance CNC machining processes. As a result, the medical industry can expect more sophisticated and reliable components suitable for a wide array of applications.

Future Trends in CNC Machining for the Medical Industry

The future landscape of CNC machining in the medical sector is poised for significant transformation, driven by emerging trends and technological advancements. One of the most notable developments is the integration of automation and robotics into CNC processes. This evolution allows for enhanced efficiency, precision, and consistency in producing medical components such as surgical tools, implants, and diagnostic devices. By employing automated systems, manufacturers can streamline operations, reduce human error, and ultimately lower costs, making high-quality medical solutions more accessible.

Another pivotal trend is the growing adoption of additive manufacturing, commonly known as 3D printing. This innovative technology enables the production of complex geometries which are not achievable through traditional machining methods. With the capability to fabricate customized solutions quickly and economically, additive manufacturing is becoming a vital component in the production of personalized medical devices tailored to individual patients’ needs. The potential for rapid prototyping also accelerates the development process, resulting in quicker advancements in medical solutions that can improve patient outcomes.

The demand for customized medical solutions is further fueled by an aging population and the rise of chronic health issues, prompting healthcare providers to seek tailored approaches. CNC machining is at the forefront of this demand, as it allows for the precise fabrication of unique components designed to meet specific medical requirements. This need for customization is indicative of a broader trend towards patient-centric care in the healthcare sector.

Industry experts predict that these trends will not only enhance the production capabilities of precision components in the medical field but also reshape the industry as a whole. By embracing automation, additive manufacturing, and customization, the medical industry can leverage CNC machining to address evolving needs, ultimately improving the efficacy and efficiency of healthcare delivery.