Introduction to Precision CNC Machining in the Medical Field

Precision CNC machining plays a pivotal role in the medical industry, facilitating the production of high-quality components essential for various medical applications. This advanced manufacturing process utilizes computer numerical control to ensure that intricate designs and specifications are adhered to with remarkable accuracy. As the healthcare sector continues to evolve, the demand for precision-driven components is more evident than ever, underscoring the significance of CNC machining in the production of medical devices.

The medical industry is subject to rigorous regulatory standards, necessitating the production of components that not only meet but often exceed these requirements. Precision CNC machining allows manufacturers to create components with tight tolerances, ensuring the reliability and functionality of devices such as surgical instruments, implants, and diagnostic equipment. By employing state-of-the-art CNC technology, manufacturers are equipped to produce parts that exhibit excellent dimensional stability, surface finish, and overall performance, which are all critical characteristics in medical applications.

Furthermore, the versatility of CNC machining allows for the use of a variety of materials, ranging from biocompatible plastics to durable metals, each chosen based on specific medical requirements. This flexibility enables manufacturers to tailor components to the needs of innovative medical applications, thereby increasing the potential for advancements in healthcare solutions. As a result, precision CNC machining not only enhances product quality but also contributes significantly to the safety and efficacy of medical devices.

In conclusion, the integration of precision CNC machining within the medical field underscores its vital role in ensuring the production of components that adhere to the highest quality standards. By leveraging advanced technologies, the medical industry can continue to innovate, ultimately leading to improved patient outcomes and healthcare solutions.

The Importance of Precision in Medical Devices

In the medical industry, the demand for precision in device manufacturing cannot be overstated. Medical devices often play a pivotal role in diagnosing, treating, and managing patient care, and thus, their functionality heavily relies on precise fabrication. Accuracy in dimensional specifications is crucial because even the slightest deviation can have dire implications for patient safety and device efficiency.

Devices such as surgical instruments, implants, and diagnostic machines require exceptionally accurate components to perform optimally. For example, an implant with incorrect specifications may lead to complications, causing harm to the patient or necessitating revision surgeries. Furthermore, surgical instruments that do not meet precise dimensions can hinder a surgeon’s ability to perform delicate procedures, resulting in increased risks during operations.

Moreover, the integration of precision CNC machining technology has revolutionized the quality control of medical components. CNC (Computer Numerical Control) machining allows for the meticulous production of parts with tolerances that are exceptionally tight. This level of accuracy not only enhances the performance of medical devices but also reinforces compliance with stringent regulatory standards. Regulatory agencies are increasingly scrutinizing the quality of medical components, mandating rigorous testing and validation to ensure that they meet the required specifications for safety and efficacy.

In summary, precision is a fundamental aspect of medical device manufacturing that directly influences the safety and health outcomes of patients. Adopting advanced machining techniques and stringent quality assurance processes ensures that medical components are produced with the necessary accuracy. As the medical industry continues to evolve, the emphasis on precision will remain essential, driving innovations that ultimately benefit patient care.

Common CNC-Machined Components Used in Healthcare

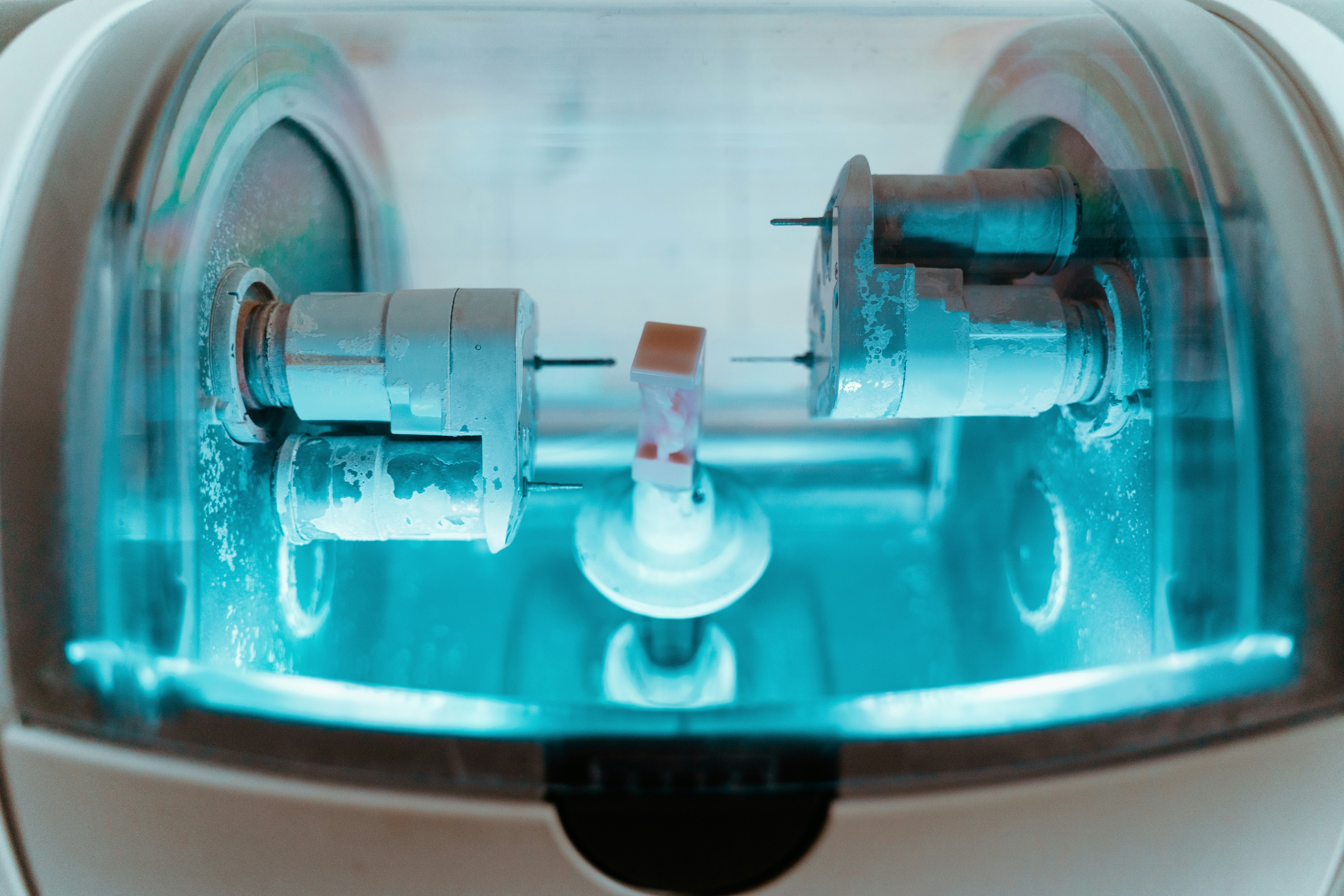

CNC machining plays a pivotal role in the medical industry by producing high-precision components that are essential for various healthcare applications. The demand for accuracy and quality in medical instruments cannot be overstated, and CNC technology delivers on these requirements consistently. Among the most common CNC-machined components used in healthcare are surgical instruments, implants, and diagnostic equipment.

One of the primary applications of CNC machining in the medical field is the production of surgical instruments. These tools include scalpels, forceps, and scissors, all of which require exceptional precision in their manufacturing processes to ensure they perform adequately during surgical procedures. The intricate designs and the need for ergonomic considerations make CNC machining an ideal choice for crafting these instruments. Customization is also possible, allowing manufacturers to meet specific needs that may arise in various surgical specialties.

In addition to surgical instruments, implants represent another significant application of CNC machining in healthcare. Components such as orthopedic implants, dental implants, and vascular stents necessitate a tailored approach since they must fit perfectly within the human body. The materials used, which can range from titanium to bio-compatible polymers, require precise CNC machining techniques to achieve the desired levels of strength and biocompatibility. Each implant must meet rigorous industry standards, and the precision offered by CNC technology ensures that they do.

Moreover, diagnostic equipment such as imaging devices, analytical instruments, and laboratory equipment also benefit from CNC machining. These components often require complex geometries and tight tolerances, which CNC manufacturing can provide flawlessly. This accuracy is vital for the reliability and efficiency of diagnostic procedures, further underscoring the reliance of the medical field on high-quality CNC-machined parts.

Materials Used in Precision Medical CNC Machining

In the medical industry, the selection of materials for precision CNC machining is paramount, given the stringent requirements for biocompatibility, durability, and reliability. Various materials are utilized, each offering unique properties that cater to different applications within the medical sector.

Metals are among the most commonly used materials in medical CNC machining, with stainless steel and titanium being particularly prominent. Stainless steel is favored for its corrosion resistance, mechanical strength, and ease of sterilization, making it ideal for surgical instruments and implants. Titanium, on the other hand, is renowned for its excellent biocompatibility and lightweight nature, which minimizes patient discomfort in implant applications. Both metals excel in demanding environments, ensuring longevity and optimal performance in various medical applications.

Plastics also play a crucial role in the manufacturing of medical components. Materials like polyether ether ketone (PEEK) and polycarbonate are frequently chosen due to their high strength-to-weight ratios, chemical resistance, and ability to withstand sterilization processes. PEEK, for instance, is exceptionally resistant to harsh chemicals and demonstrates good biocompatibility, making it suitable for implantable devices and surgical tools. Polycarbonate, being lightweight and shatter-resistant, is often used for medical devices requiring transparency, like housings for monitoring equipment.

Ceramics are another category of materials utilized in precision medical CNC machining. Although less common than metals and plastics, ceramics such as alumina and zirconia are prized for their high wear resistance, biocompatibility, and ability to resist chemical corrosion. These properties make ceramics an excellent choice for dental implants and prosthetic applications. Each of these materials offers distinctive advantages that contribute to the overall functionality and safety of medical devices, ensuring that precision CNC machining meets the rigorous demands of the healthcare industry.

ISO Standards and Regulatory Compliance in Medical Manufacturing

In the realm of medical manufacturing, adherence to ISO standards and regulatory compliance is paramount for ensuring that precision CNC components meet the safety and effectiveness required for healthcare applications. Various ISO standards govern the quality management processes essential for manufacturers in this sector. Notably, ISO 13485 outlines the requirements for a comprehensive quality management system specifically tailored for medical devices. Compliance with this standard ensures that organizations consistently meet regulatory requirements and enhance customer satisfaction, thereby fostering trust within the medical community.

Additionally, manufacturers must also consider ISO 9001, which focuses on quality management and sets the criteria for an organization’s ability to deliver consistent, effective products. The integration of these standards plays a critical role in the production of high-precision components, as they provide a framework that leads to continuous improvement in manufacturing processes and operational efficiency.

Regulatory bodies, such as the FDA in the United States or the EMA in Europe, impose their own sets of guidelines and standards that manufacturers of medical devices must comply with. Compliance with these regulations not only ensures the safety and efficacy of medical components but also serves as a benchmark for manufacturers. Certifications from relevant bodies signal to healthcare providers and consumers that the components produced meet stringent safety and quality requirements.

Moreover, achieving compliance and maintaining ISO certifications are indicators of a manufacturer’s commitment to quality and reliability. It assures stakeholders that the manufacturer has implemented rigorous processes to mitigate risks associated with medical device production. This trust, built through demonstrated adherence to ISO standards and regulatory requirements, is crucial in a field where the stakes are significantly high, and the necessity for precision is non-negotiable.

Technological Advancements in CNC Machining for Medical Applications

The medical industry is continually evolving, driven by the need for precise components that meet stringent standards. Recent advancements in Computer Numerical Control (CNC) machining have significantly enhanced the quality and accuracy of manufacturing processes in this sector. One of the most notable trends is the integration of automation technologies. Automated CNC machines reduce human error, increase production speed, and maintain consistent quality by operating seamlessly for extended periods. This is particularly important in medical applications where even minor deviations can lead to severe consequences.

Another significant development in CNC machining for the medical sector is the incorporation of artificial intelligence (AI) and machine learning algorithms. These technologies enhance the predictive maintenance of CNC machines, allowing for real-time monitoring of performance and proactive adjustments to ensure optimal functioning. With AI, CNC systems can analyze vast amounts of data to anticipate when maintenance is needed, thus preventing downtime and ensuring that precision components are produced in a timely manner. This level of efficiency is critical in medical manufacturing, where time-sensitive product delivery can impact patient care.

Enhanced software solutions also play a crucial role in modern CNC machining. Advanced Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software now allow for more intricate designs and simulations before actual production begins. This capability enables manufacturers to tailor components specifically for medical applications, ensuring functionality and compatibility within various medical devices. The integration of virtual reality (VR) in the design phase is another cutting-edge approach that allows engineers to visualize and interact with components in a simulated environment, further reducing the likelihood of errors and increasing precision.

As technology progresses, these innovations in CNC machining will continue to push the boundaries of quality and accuracy in the medical industry, facilitating the production of components that meet the highest standards required for effective medical solutions.

Challenges in Producing Precision CNC Components for Medicine

The production of precision CNC components for the medical industry is fraught with a variety of challenges that manufacturers must navigate to ensure quality and accuracy. One of the primary challenges stems from material limitations. The medical sector often requires components made from specialized materials that not only meet stringent health and safety standards but also offer the necessary durability and biocompatibility. This selection process can be complicated and requires a thorough understanding of material properties and how they interact within a biological environment.

Another significant challenge involves technological hurdles. The design and manufacture of CNC components necessitate a high level of precision and accuracy, often pushing the limits of conventional machining techniques. Advanced CNC machinery, such as 5-axis mills and precision lathes, is essential to produce the intricate designs often required in medical applications. However, such technology can be costly, necessitating continuous investment in training and maintenance to ensure that operators are proficient in using the sophisticated equipment effectively.

Furthermore, the fluctuating landscape of regulatory pressures presents an additional layer of complexity. The medical industry is one of the most regulated sectors, with agencies such as the FDA imposing strict guidelines on the manufacturing processes of medical devices. Compliance with these regulations requires manufacturers to implement rigorous quality control measures and documentation practices, which can be both time-consuming and resource-intensive. As a consequence, manufacturers often find it challenging to balance the need for innovation with the need for regulatory compliance, as delays in approval can hinder production timelines and adversely affect business operations.

In essence, manufacturers of precision CNC components for the medical field must skillfully navigate these challenges to deliver reliable and effective solutions to meet the evolving needs of the healthcare sector.

Case Studies: Successful Applications of CNC Machined Medical Components

The precision and reliability of CNC machined components play a crucial role in the medical industry, where even the smallest errors can significantly impact patient outcomes. Several case studies demonstrate the transformative impact of these components across various applications in healthcare.

One notable example is the production of surgical instruments, where a prominent medical device manufacturer implemented CNC machining to create highly precise scalpel blades. By utilizing advanced CNC technology, the company achieved a remarkable reduction in production time while maintaining stringent quality standards. This transition not only improved the efficiency of their manufacturing processes but also ensured that the surgical instruments met the rigorous specifications required for successful surgical procedures. The result was a notable enhancement in surgical precision, minimally invasive techniques, and ultimately, patient safety.

Another significant case study involves the creation of implantable medical devices, such as orthopedic implants. A leading orthopedic implant manufacturer adopted CNC machining techniques to produce custom implants specifically designed to fit the unique anatomical needs of individual patients. With the aid of 3D modeling software and precision CNC machinery, the company successfully produced implants that not only improved fit and comfort but also accelerated the healing process. The feedback from patients and healthcare providers highlighted the superior quality of these implants, leading to higher satisfaction rates and improved clinical outcomes.

Moreover, dental applications have also benefited from CNC machined components. A dental lab incorporated CNC technology to craft crowns and bridges with unmatched accuracy. The speed and precision of CNC machining allowed for custom solutions tailored to individual patients, which resulted in a significant improvement in overall dental care. This integration of technology has set new standards in the dental field, showcasing the broad applicability and benefits of CNC machined components in enhancing patient care.

Conclusion: The Future of CNC Machining in Healthcare

As the medical industry continues to evolve, the role of precision CNC machining becomes increasingly critical. Advanced manufacturing techniques, including CNC machining, play a pivotal role in meeting the rigorous demands of healthcare. The continuous need for high-quality medical components necessitates innovations that ensure accuracy, reliability, and compliance with stringent regulations. Looking ahead, it is essential for manufacturers to embrace new technologies and methodologies to maintain a competitive advantage.

One prominent trend shaping the future of CNC machining in the medical sector is the integration of automation and artificial intelligence. These advancements not only enhance precision but also significantly increase production efficiency. By adopting smart manufacturing practices, companies can reduce the time to market for essential medical devices, which is especially crucial in times of health emergencies.

Furthermore, with the growing emphasis on personalized medicine, manufacturers must be prepared to produce intricate and customized components. CNC machining allows for the fabrication of precise parts tailored to individual patient needs, thereby improving patient outcomes and fostering innovation in medical treatments. The ability to rapidly prototype and iterate on designs will be invaluable as healthcare continues to prioritize individualized care.

Additionally, sustainability is becoming a key consideration in manufacturing processes. The medical industry is increasingly focused on reducing waste and minimizing environmental impacts. CNC machining can contribute to this goal through efficient material use and the capability to recycle components. By adopting sustainable practices, manufacturers can not only comply with emerging regulations but also enhance their brand reputation in a discerning market.

In conclusion, the future of CNC machining in healthcare is characterized by continual advancements in precision, customization, and sustainability. To thrive, manufacturers must remain agile, leveraging technological innovations and adapting to the ever-changing medical landscape. By doing so, they ensure the delivery of high-quality medical components that meet the demands of both healthcare professionals and patients alike.