Introduction to CNC Turning

CNC turning represents a pivotal process in modern manufacturing, encompassing both the sophistication of technology and the precision required for creating components. The term “CNC” stands for Computer Numerical Control, which refers to the automated machining process that utilizes computer systems to control machine tools. This method facilitates high levels of accuracy and replicability, qualities that are essential in various manufacturing sectors. CNC turning specifically involves rotating the workpiece against a stationary cutting tool, allowing for the creation of cylindrical parts with exceptional dimensional precision.

The significance of CNC turning lies in its ability to produce intricate shapes and features that traditional machining methods struggle to achieve. By employing advanced software, operators can input complex designs, which the machines execute with remarkable consistency. This process is enhanced by the use of tools that are automatically changed based on the selected operation, thereby streamlining production and reducing the potential for human error. Industries, including automotive, aerospace, and medical manufacturing, have embraced CNC turning due to its efficiency and ability to maintain tight tolerances.

One of the distinguishing features of CNC turning is its versatility. It can efficiently machine a variety of materials, from metals like aluminum and steel to plastics and composites. This adaptability ensures manufacturers can meet diverse demands by tailoring the production process to the specifications of each project. Furthermore, CNC turning contributes to cost-effectiveness; even with an initial investment in technology and training, the long-term savings from reduced waste and enhanced productivity are significant.

In summary, CNC turning serves as a cornerstone of modern industrial practices, driven by its precision machining capabilities and broad applicability across numerous sectors. This technology not only enhances the quality of produced parts but also aligns with the evolving needs of the manufacturing industry.

What are CNC Turned Parts?

CNC turned parts refer to components that are manufactured using a process known as computer numerical control (CNC) turning. This method involves the rotation of a workpiece, typically made of metal or plastic, against a cutting tool to achieve desired shapes and dimensions. The CNC turning process is known for its precision, allowing for the production of highly complex and intricate designs that may be challenging to achieve with other manufacturing techniques.

One of the distinguishing features of CNC turned parts is their cylindrical shape, which is produced through the lathe operation. This process enables the creation of components with uniform diameters, smooth surfaces, and exact measurements. CNC turning is particularly well-suited for producing a variety of parts, ranging from simple knobs to complex components utilized in aerospace, automotive, and medical applications. The capability to create parts with tight tolerances makes CNC turning a preferred choice in industries where precision is paramount.

When comparing CNC turned parts to other manufacturing methods, such as milling or grinding, several unique characteristics emerge. Unlike milling, which involves the removal of material from a stationary workpiece, CNC turning allows for continuous rotation, thus enhancing efficiency and reducing production time. Additionally, CNC turning is particularly effective for batch production, where consistent quality and rapid turnaround are critical. The versatility of CNC turning extends beyond merely producing cylindrical parts; it also enables the incorporation of features such as grooves, threads, and contours, further broadening its application range.

In summary, CNC turned parts are integral components in modern manufacturing, distinguished by their precision and adaptability. The unique characteristics of the CNC turning process facilitate the creation of complex geometries that satisfy the stringent requirements of various industries, emphasizing its importance in contemporary engineering solutions.

Materials Used in CNC Turning

CNC turning is a widely adopted manufacturing process, primarily due to the variety of materials that can be effectively machined through this method. The selection of material plays a crucial role in determining the final properties of the turned parts, influencing performance, strength, and suitability for various applications across different industries.

Metals are among the most common materials employed in CNC turning. Various alloys, such as aluminum, steel, and titanium, are frequently used due to their excellent machinability and mechanical properties. Aluminum is lightweight and exhibits outstanding corrosion resistance, making it ideal for automotive and aerospace applications. Steel offers higher strength and durability, making it suitable for heavy-duty components. Titanium, noted for its high strength-to-weight ratio and resistance to extreme environments, is extensively utilized in aerospace and medical devices.

Aside from metals, plastics also play a significant role in CNC turning operations. Commonly used plastics include polycarbonate, nylon, and acrylic. These materials provide lower weight and are often more cost-effective than metals for certain applications. Plastics can be machined into intricate designs while maintaining excellent surface finishes, making them preferred choices for prototypes, consumer products, and electronic housings.

Furthermore, composites are garnering attention in CNC turning due to their unique properties. These materials, usually a combination of two or more constituents, are engineered to provide enhanced strength-to-weight ratios and improved durability. Composites are increasingly utilized in sports equipment, automotive parts, and aerospace structures where performance and weight efficiency are critical.

In summary, the choice of materials used in CNC turning is essential, as it directly impacts the functionality and application of the manufactured parts. By understanding the properties of metals, plastics, and composites, manufacturers can make informed decisions that align with the specific requirements of different industries.

The CNC Turning Process Explained

The CNC turning process is a sophisticated technique widely employed in the manufacturing industry to create precise components from various materials. It generally begins with the setup of the CNC machine, which is crucial for ensuring accuracy and efficiency throughout the operation. Initially, the operator selects the appropriate lathe and tooling system tailored for the specified material and part design. Common materials utilized in CNC turning include metals like aluminum, steel, and brass, as well as plastics.

Once the machine is properly set, the next step involves loading the raw material, typically cylindrical bar stock, onto the lathe. This material is securely clamped in the machine’s chuck, allowing it to rotate with precision. Following this, the CNC software is programmed with the necessary specifications, which include dimensions, tolerances, and surface finishes. This programming can be accomplished using G-code, a language that instructs the CNC machine on how to perform each operation.

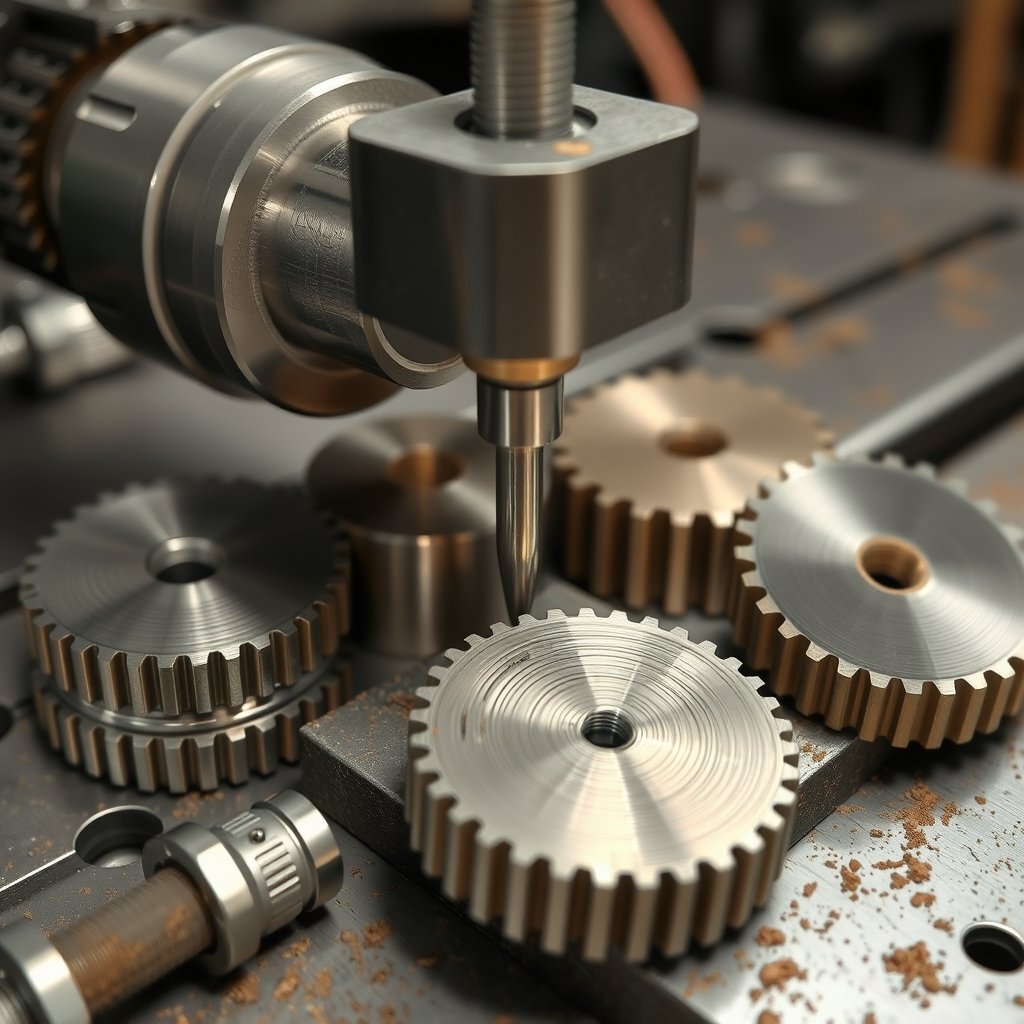

After the programming phase, the CNC machine executes the turning operation. The cutting tool, which is held in a stable position, engages the spinning material, gradually removing excess material to create the desired shape. Various techniques are employed during this phase, including rough turning, which removes large amounts of material quickly, and finish turning, which refines the surface for final specifications. Tooling options such as carbide inserts, high-speed steel tools, and custom-form tools are often utilized depending on the requirements of the part being produced.

In addition to these fundamental steps, CNC turning can incorporate various additional processes such as drilling and threading to further enhance the functionality of the finished part. The adaptability and precision of the CNC turning process make it an essential method for producing high-quality components across numerous applications in automotive, aerospace, and consumer products. Ultimately, mastering the intricacies of CNC turning leads to improved manufacturing efficiency and product quality.

Applications of CNC Turned Parts

CNC turned parts are integral components in a variety of industries due to their precision, efficiency, and versatility in manufacturing. One of the most significant applications can be found in the automotive sector, where CNC turning plays a pivotal role in producing parts such as shafts, bushings, and mounting brackets. These components require intricate geometries and tight tolerances, making CNC machining an ideal method to ensure high-quality results that meet rigorous safety and performance standards.

In the aerospace industry, CNC turned parts are utilized in the manufacturing of critical components including brackets, fittings, and housings that must withstand extreme environmental conditions. The accuracy and repeatability of CNC turning enable manufacturers to produce lightweight, strong parts that are vital for maintaining the performance and safety of aircraft. By employing advanced materials such as aluminum and titanium, the aerospace sector greatly benefits from the capabilities of CNC machining, ensuring both strength and weight optimization.

The medical device industry also relies heavily on CNC turned parts for intricate components such as surgical instruments and implants. Due to the stringent regulations and high standards that govern medical devices, the precision afforded by CNC turning is crucial. For example, the production of components like orthopedic screws and gear mechanisms requires an exceptional level of accuracy and surface finish, which CNC turning can deliver consistently. This precision is further enhanced through the utilization of biocompatible materials, ensuring safety for end-users.

Additionally, the consumer electronics sector employs CNC turned parts in manufacturing items such as housings, connectors, and various brackets for electronic devices. The increasing demand for compact and high-performance electronic products places a premium on the quality of the components used. CNC turning provides the ability to quickly prototype and produce parts efficiently, meeting the fast-paced nature of this industry.

Benefits of Using CNC Turned Parts

CNC turned parts offer significant advantages compared to traditional machining methods, making them an excellent choice for various manufacturing applications. One of the primary benefits is precision. CNC (Computer Numerical Control) technology utilizes advanced software and machinery to perform tasks with high accuracy. This level of precision is critical in sectors like aerospace and medical device manufacturing, where tight tolerances are mandatory. Traditional machining methods often struggle to achieve such accuracy consistently, leading to variations that can compromise product quality.

Another key advantage is repeatability. CNC turning processes can consistently produce identical parts with minimal deviation from specifications. This repeatability is essential for businesses aiming to meet high production demands without sacrificing quality. Unlike manual machining, which can be subject to human error, CNC machines operate based on calculated data, ensuring that each turned part is produced under the same conditions.

Efficiency is also a vital factor in choosing CNC turned parts. CNC machines operate with a higher speed and can usually run unattended for extended periods. This capability allows manufacturers to increase their production rates significantly, thereby reducing lead times and improving overall workflow. The automation of CNC turning processes minimizes downtime, allowing businesses to fulfill orders more quickly and effectively.

Cost-effectiveness is another noteworthy benefit. While the initial setup of CNC machinery can be substantial, the long-term savings associated with reduced labor costs, lower material wastage, and higher production rates often outweigh these initial expenditures. Additionally, CNC turning can create complex geometries that may be challenging or impossible to achieve with traditional methods. This ability to produce intricate designs opens up possibilities for innovative applications and product development.

Challenges in CNC Turning

CNC turning is a widely utilized manufacturing process that involves the removal of material to create precision components. However, this technique is not without its challenges, which can impact both the efficiency and quality of the final product. One significant challenge is the potential for human error. Even with automated systems, operators must engage in programming and monitoring processes that require a high level of skill and attention to detail. Inadequate training can lead to mistakes in setup or programming, which can compromise production accuracy.

Another challenge lies in machine maintenance. CNC turning machines are sophisticated tools that require regular upkeep to function optimally. Neglecting maintenance can result in decreased precision, increased wear on tools, and even machine breakdowns, which can interrupt production schedules and lead to increased operational costs. Operators and maintenance staff must remain vigilant in their responsibilities to ensure that all components of the CNC equipment are in working order.

Furthermore, there are inherent limitations in producing certain geometries. While CNC turning excels at creating cylindrical shapes and features, intricate designs or complex geometries may require additional processes, such as CNC milling or electrical discharge machining (EDM). This necessity can complicate the production workflow and may lead to longer lead times.

Additionally, the significance of proper programming cannot be overstated. Each component must be programmed with precision to ensure that the cutting tool behaves as intended. A well-trained operator is crucial in preemptively addressing potential issues that may arise during the turning process. Continuous education and investment in operator skills are key factors in overcoming challenges associated with CNC turning, ultimately leading to enhanced productivity and superior-quality parts.

Future Trends in CNC Turning Technology

The landscape of CNC turning technology is rapidly evolving, with several promising trends anticipated to shape its future. One of the most significant advancements is the integration of automation into CNC turning processes. Automated CNC machines are increasingly being employed to enhance efficiency, reduce human error, and lower production costs. By utilizing robotics and machine learning algorithms, manufacturers can optimize machining operations, leading to faster turnaround times and improved throughput. This shift toward automation not only streamlines production but also allows skilled operators to focus on complex tasks that require human insight.

Another notable trend is the improvement of software applications used in Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM). Advances in software capabilities are enabling engineers and designers to create more intricate and precise designs. Enhanced simulation tools facilitate a virtual environment where potential issues can be identified and rectified before actual production begins. As a result, the integration of improved software is expected to minimize material waste and increase overall product quality. In addition, user-friendly interfaces are empowering more individuals to engage in CNC turning, expanding the talent pool within the manufacturing sector.

The impact of Industry 4.0 on CNC turning is also noteworthy. This new industrial revolution focuses on the interconnectivity of machines, data, and people through the Internet of Things (IoT). The implementation of smart manufacturing practices is expected to lead to higher levels of customization, as companies can now leverage data analytics to better understand market demands and customer preferences. Ultimately, these innovations will not only enhance the capabilities of CNC turning technology but also elevate operational efficiency across the manufacturing spectrum. The future of CNC turning is poised for a transformation that embraces technology to drive productivity and meet evolving market needs.

Conclusion

In summary, CNC turned parts play a vital role in the manufacturing sector, providing precision and efficiency that traditional methods often struggle to achieve. The process of CNC turning utilizes computer numerical control technology to create intricate designs and components with exceptional accuracy. This advanced manufacturing technique allows for the production of various components across multiple industries, including automotive, aerospace, and medical sectors.

Throughout this guide, we have highlighted the importance of CNC turned parts in ensuring product quality and consistency. The ability to automate production minimizes human error while maximizing throughput, making CNC turning an advantageous choice for manufacturers looking to improve their processes. Moreover, the versatility of materials that can be used in CNC turning, ranging from metals to plastics, further emphasizes its applicability in diverse projects.

It is essential for companies to consider their specific needs when evaluating CNC turning for their component requirements. Key factors such as design specifications, material selection, and production volume should be thoroughly assessed to ensure that the chosen approach aligns with project objectives. By understanding the unique benefits that CNC turned parts offer, manufacturers can leverage this technology to enhance their production capabilities and drive efficiency.

Overall, embracing CNC turning not only contributes to achieving high-quality results but also fosters innovation in product development. It is an approach that aligns well with modern manufacturing demands, ensuring that businesses remain competitive in an ever-evolving market landscape. Moving forward, organizations should remain open to the possibilities that CNC turned components can provide while weighing the advantages against their specific manufacturing goals.