Introduction to Precision CNC Parts

Precision CNC parts are intricately machined components produced using Computer Numerical Control (CNC) machining, a process that utilizes computers to control the movement of machinery. These parts are characterized by their high accuracy and tight tolerances, often exceeding ±0.001 inches. Precision CNC parts differ significantly from standard components in their manufacturing process, materials used, and the resulting levels of detail and performance. They are essential in sectors where precision and reliability are non-negotiable.

The significance of precision CNC parts in manufacturing cannot be overstated. They are widely employed in industries such as aerospace, automotive, electronics, and medical devices, where the performance of each component is crucial for the overall functionality of an assembly or system. For instance, in aerospace engineering, even a slight deviation in a component’s dimensions could lead to catastrophic failure. As such, manufacturers utilize precision CNC machining to achieve the exact specifications needed for complex parts that meet rigorous safety and quality standards.

Unlike standard components, which may allow for minor discrepancies, precision CNC parts require a meticulous approach to their design and production. These components often incorporate advanced materials, including titanium, aluminum, and high-grade plastics, allowing them to withstand extreme conditions such as high temperatures, pressure, or corrosive environments. The applications of precision CNC parts are vast, ranging from intricate turbine blades in jet engines to tightly fitted gears in automobiles, highlighting their versatility and essential role in the advancement of modern technology.

As industries continue to evolve towards automation and higher efficiencies, the demand for precision CNC parts is expected to grow, making them indispensable in the pursuit of innovation and excellence in manufacturing.

The CNC Machining Process Explained

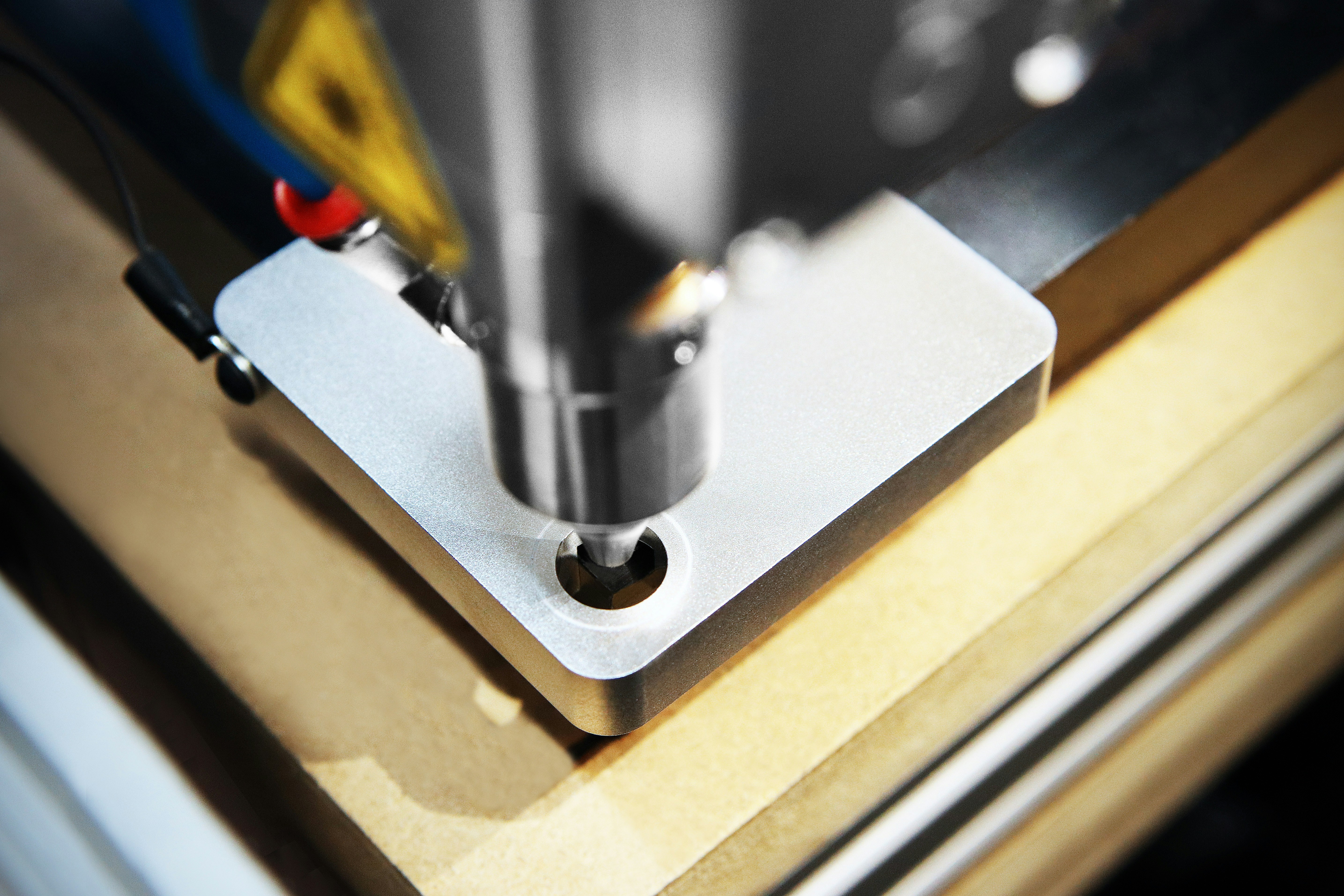

The CNC (Computer Numerical Control) machining process is a sophisticated method of producing precision parts using automated machinery. At its core, CNC machining involves the use of computers to control machine tools, allowing for increased accuracy and consistency in manufacturing. This process has revolutionized the way parts are produced, moving from manual machining to automated techniques that significantly enhance production capabilities.

CNC machines come in various forms, including milling machines, lathes, and routers. Each type of CNC machine serves specific functions, depending on the requirements of the fabrication process. For instance, milling machines are used for cutting and shaping materials, while lathes are better suited for producing cylindrical parts. Routers excel in cutting intricate patterns and designs in various materials such as wood, plastics, and metals. The versatility of these machines contributes to the precision and efficiency of CNC machining.

The programming languages used in CNC machining are crucial for directing the machines on how to perform tasks. The most common language is G-code, which consists of a series of commands that instruct the CNC machine on movement, speed, and other operational parameters. Operators input the designs into the CNC software, which translates the programming into coordinated movements that the machine executes. Advances in technology have led to sophisticated software systems that enhance the programming process, making it more intuitive and user-friendly.

The CNC machining process typically follows several key steps. First, a design is created and inputted into the CNC software. Next, the machine is set up with the necessary tools and material. Following this, the machine executes the programmed instructions, which involves cutting, drilling, or shaping the material as needed. Finally, quality control checks are performed to ensure that the produced parts meet the required specifications. Over the years, CNC machining technology has evolved, incorporating advancements such as automation, real-time monitoring, and increased precision, making it an indispensable process in modern manufacturing.

Materials Used in CNC Precision Engineering

Precision CNC machining leverages a diverse array of materials to produce high-quality parts tailored to specific applications. The selection of material significantly influences the final product’s performance, durability, and overall cost. Among the most commonly used materials are metals, plastics, and composites.

Aluminum is a prevalent choice in CNC precision parts due to its lightweight nature and excellent machinability. It offers a good strength-to-weight ratio, which makes it suitable for applications in aerospace and automotive industries. Additionally, aluminum has good corrosion resistance, making it an ideal material for components exposed to harsh environments. However, the relatively lower tensile strength compared to steel may limit its use in heavy-load applications.

Titanium is another popular metal, recognized for its exceptional strength and corrosion resistance. Its high strength-to-weight ratio is particularly advantageous in applications requiring both durability and weight savings. However, titanium can be more challenging to machine, leading to higher production costs. Therefore, it is often reserved for specialized applications such as medical devices and high-performance aerospace components.

Steel, particularly stainless steel, is renowned for its strength, making it suitable for demanding environments. Its durability and resistance to wear make it ideal for precision engineering components, such as gears and shafts. However, steel’s weight can be a drawback in applications where weight is a critical factor.

Plastics, including acrylonitrile butadiene styrene (ABS) and polycarbonate, are also widely used in CNC machining. These materials are lightweight and often more cost-effective than metals, making them suitable for prototypes and applications where a lower strength is acceptable. Nonetheless, plastics may lack insulation against heat and are generally not as durable as metals.

Lastly, composites, which blend materials such as ceramics or carbon fibers with polymers, provide tailored properties for specific applications, often combining the best attributes of their components. The versatility of composites is beneficial in sectors where both weight and strength are necessary; however, they can be complex to machine and usually come at a higher cost. Selecting the right material is essential for optimal performance in CNC precision engineering.

Key Features of Precision CNC Parts

Precision CNC parts are integral to various industries where accuracy and reliability are paramount. One of the primary features that define these components is their tolerance levels. Tolerance refers to the allowable deviation from specified dimensions, which can significantly affect the functionality of the part. In precision machining, tolerances are often measured in thousandths of an inch (or microns), and tighter tolerances result in higher quality components. This aspect is crucial in sectors such as aerospace and automotive, where minute discrepancies can lead to significant operational failures.

Another essential characteristic is surface finish. The surface quality of a CNC part can influence its performance by affecting friction, wear resistance, and overall aesthetic appeal. Different applications may require specific surface finishes, which can range from rough textures designed for better adhesion to smooth finishes that minimize friction. Understanding the specific surface finish needed for a particular application is vital for ensuring optimal performance and longevity of the part.

Accuracy is also a critical feature of precision CNC parts. It refers to how closely a manufactured part matches its intended design specifications. High accuracy in CNC machining is achieved through advanced computer technology and precision tooling, allowing for complex shapes and intricate details to be cut with exact precision. Consistency is equally important; the ability to produce identical parts repeatedly ensures reliability in manufacturing processes. In industries where precision is non-negotiable, both accuracy and consistency are critical to maintaining quality standards.

These key features—tolerance levels, surface finishes, accuracy, and consistency—not only define precision CNC parts but also directly impact their performance and reliability across various applications. A comprehensive understanding of these characteristics is essential for engineers and manufacturers aiming to achieve quality results in their projects.

Applications of Precision CNC Parts in Various Industries

Precision CNC parts have become essential in an array of industries due to their ability to produce components with unmatched accuracy and consistency. In the aerospace sector, for example, CNC machining is crucial for the fabrication of lightweight, high-strength parts such as turbine blades and fuselage components. These parts must meet strict safety and performance standards, and the precision offered by CNC machining ensures that they fit correctly and perform reliably under extreme conditions.

Similarly, the automotive industry increasingly relies on precision CNC parts in the production of critical components like engine blocks and transmission housings. These intricate parts require detailed specifications and tolerances to ensure optimal performance and fuel efficiency. The automation provided by CNC technology not only speeds up production times but also enhances quality control, minimizing the risk of defects that could compromise vehicle safety.

The medical field also benefits significantly from precision CNC machining. Instruments, implants, and surgical tools are often made from materials like titanium and stainless steel, which are processed using CNC methods to achieve the necessary precision and finish. For instance, orthopedic implants, to be properly fitted and functional, demand meticulous design and fabrication, which CNC machining reliably provides.

In the electronics industry, precision CNC parts play a vital role in the manufacturing of circuit boards, connectors, and casings. The high precision and reproducibility of CNC processes ensure that electronic components meet performance criteria, facilitating better efficiency and longevity. As technology evolves, the need for smaller, more intricate components continues to rise, making CNC machining an invaluable resource.

Other industries, such as pharmaceuticals and defense, also utilize precision CNC parts to enhance productivity and safety. The consistent quality and efficiency of CNC machined components allow these sectors to operate at high standards while minimizing risk. As industries demand more intricate designs and higher volumes, precision CNC parts will remain integral to technological advancement and operational success.

Advantages of Using Precision CNC Parts

Precision CNC parts provide numerous advantages over traditional manufacturing methods, making them a preferred choice in various industries. One of the most significant benefits is the enhanced accuracy they offer. CNC machines operate with a high degree of precision, ensuring that every part produced meets stringent tolerances. This level of accuracy results in consistent outputs, mitigating issues related to human error that commonly arise in manual manufacturing processes.

Another critical advantage is the reduction of material wastage. Traditional manufacturing techniques often involve cutting and shaping materials in a less efficient manner, leading to considerable scrap. In contrast, CNC machining optimizes the use of raw materials through advanced algorithms that minimize excess waste. For instance, using a CNC router can allow for intricate designs to be cut from sheets of material with minimal leftover, thereby enhancing sustainability in production.

Additionally, precision CNC parts facilitate faster production times. The automation of CNC machining means that once a program has been created, parts can be produced quickly and continuously without the need for constant supervision. This capability is particularly beneficial for high-volume production runs and can lead to significant cost savings over time. For example, a manufacturer that transitioned to CNC machining from traditional methods experienced a 30% increase in production speed.

Moreover, the ability to produce complex designs is a hallmark of CNC machining. Traditional manufacturing may limit the complexity of shapes and sizes that can be achieved, but CNC technology allows for intricate and elaborate designs that were once impractical. This flexibility not only enables innovation but also allows manufacturers to meet specific customer requirements with ease. Consequently, precision CNC parts are indispensable tools in industries ranging from aerospace to automotive, redefining the standards of quality and efficiency.

Challenges in Producing Precision CNC Parts

The manufacturing of precision CNC parts comes with its share of challenges that can impact both efficiency and product quality. One significant issue is machine calibration. CNC machines must be calibrated correctly to ensure accurate measurements during the machining process. Any deviation from the optimal calibration can lead to discrepancies in the dimensions of the final product. Therefore, regular maintenance of the machines, including checking alignment and making necessary adjustments, is crucial in maintaining precision.

Another challenge is the complexity of designs. As technology advances, the demand for intricate and complex part designs increases. This complexity often leads to difficulties in programming the CNC machines effectively. Designers must ensure that the designs are not only functional but also feasible for machining. Engaging in prototyping and simulation can help visualize potential issues before actual production begins, thereby minimizing errors and unexpected complications.

Maintaining quality control throughout the production process is yet another challenge faced by manufacturers. Ensuring uniform quality in batches of precision CNC parts requires a robust quality assurance system that can identify and rectify defects promptly. Utilizing advanced inspection technologies—such as coordinate measuring machines (CMM)—can significantly enhance the precision of measurements, helping to maintain high-quality standards. Additionally, establishing a comprehensive quality management system that addresses various checkpoints in the manufacturing process can provide a structured approach to quality control.

To overcome these challenges, manufacturers should implement best practices such as continuous training for machine operators, investing in high-quality machinery, and adopting lean manufacturing principles. These practices not only enhance operational efficiency but also foster an environment of continual improvement, ultimately leading to the successful production of precision CNC parts.

Future Trends in Precision CNC Machining

The landscape of precision CNC machining is continuously evolving due to a variety of emerging technologies and trends that are set to redefine how components are manufactured. One significant trend is the increased adoption of automation in CNC machining processes. Automation has the potential to enhance production efficiency, consistency, and accuracy, allowing manufacturers to achieve higher levels of precision in the creation of CNC parts. This not only reduces human error but also shortens the production cycle time, thereby meeting the growing demand in various industries.

Furthermore, the integration of artificial intelligence (AI) is poised to transform precision CNC machining by enabling smarter operations. AI algorithms can analyze vast amounts of data collected during the machining process to optimize performance, predict maintenance needs, and even facilitate real-time adjustments for better outcomes. This ability to learn from past operations ensures continuous improvement, making AI a valuable asset in enhancing the precision and reliability of CNC parts manufacturing.

In addition to automation and AI, advancements in material science are significantly influencing the future of precision CNC machining. As manufacturers develop new materials with superior properties, such as increased strength, durability, and lightweight characteristics, the scope for CNC machining applications expands. Innovative materials enable the production of more complex and efficient designs, which can improve overall performance in sectors like aerospace, automotive, and medical technology.

Collectively, these trends are shaping an industry characterized by heightened precision, efficiency, and adaptability. As technology continues to advance, manufacturers of precision CNC parts will need to stay ahead of these developments to maintain a competitive edge and meet the demands of their clients effectively. By embracing automation, AI, and breakthroughs in materials, the future of precision CNC machining looks promising, paving the way for even more sophisticated manufacturing processes.

Conclusion: The Importance of Precision CNC Parts

Precision CNC (Computer Numerical Control) parts have become fundamental components in contemporary manufacturing processes across various industries. Their ability to deliver high accuracy and repeatability is indispensable for producers looking to maintain competitive advantages. As businesses continue to seek efficiency and precision, CNC machining has emerged as a crucial technology that supports these demands. With the rapid evolution of manufacturing technologies, the importance of precision CNC parts is more pronounced than ever.

The accuracy achieved through CNC machining not only minimizes material wastage but also enhances product consistency. Industries such as aerospace, automotive, and medical rely heavily on these precision components to ensure safety, reliability, and performance in their products. The rise of advanced manufacturing techniques, including additive manufacturing and hybrid processes, further amplifies the need for precision CNC parts that can be integrated seamlessly into complex designs, accommodating the growing trend of customization.

Innovation continues to drive the field of precision CNC machining forward, with advancements in software, tooling, and materials. Manufacturers are investing in state-of-the-art CNC equipment that supports multi-axis machining and real-time monitoring to enhance productivity and quality. This ongoing progress not only ensures the creation of more complex and intricate parts but also sets a strong foundation for future technologies. As the demand for high-quality precision parts surges, manufacturers are encouraged to appreciate their significant roles in various applications.

Ultimately, the evolution of precision CNC parts is a testament to the dynamic nature of the manufacturing sector. Recognizing their importance can lead to more informed decision-making for businesses seeking to leverage precision engineering to meet market demands effectively. The impact of these components on everyday technology cannot be overstated, highlighting the pivotal role they play in driving innovation and quality across industries.