Introduction to Machined Metal Parts

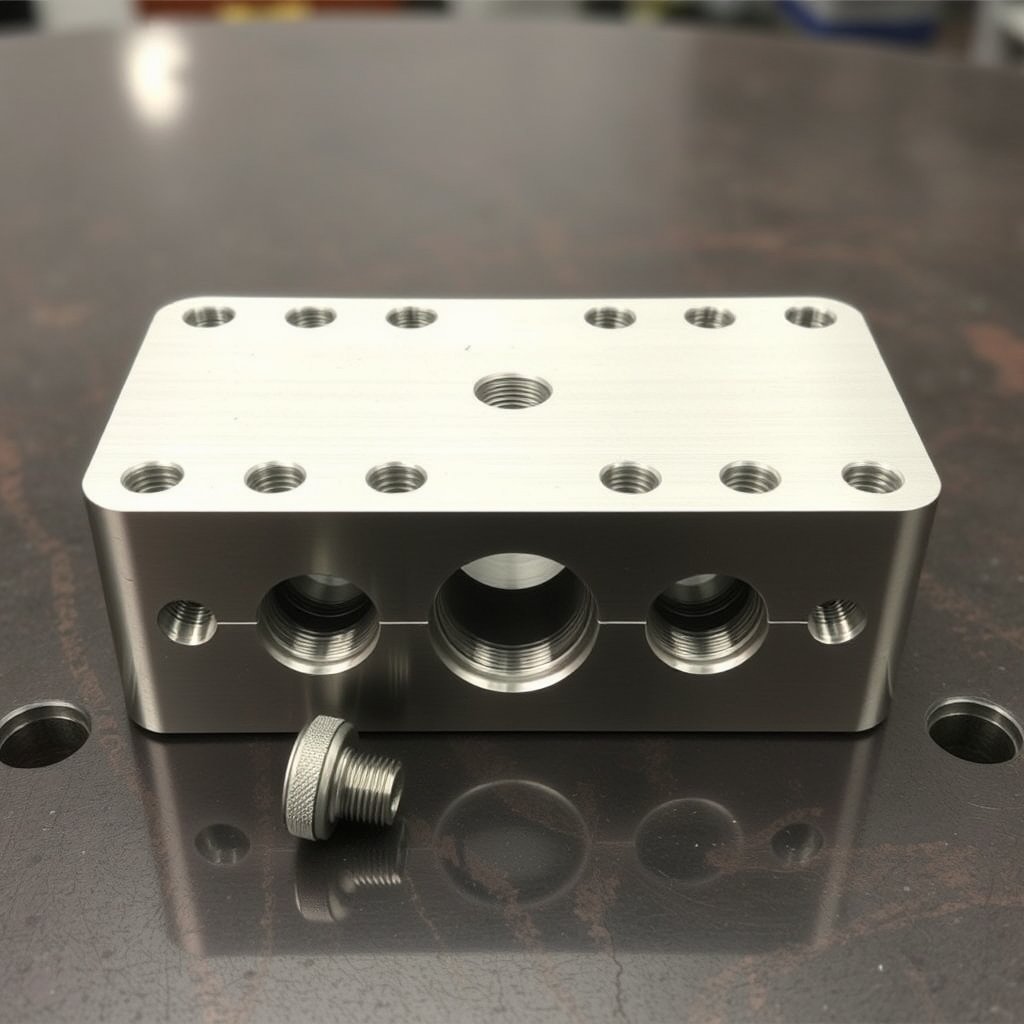

Machined metal parts are components created through various machining processes which involve the removal of material from a solid block of metal to achieve desired shapes and specifications. This progressive manufacturing technique is essential in numerous industries, including aerospace, automotive, and medical devices. The broader category of manufacturing processes encompasses various methods, such as casting, forging, and additive manufacturing, each with its distinct advantages and applications; however, machining stands out due to its precision and versatility.

In the machining process, the primary techniques include turning, milling, drilling, and grinding. These techniques utilize specialized equipment like lathes, milling machines, and CNC (Computer Numerical Control) machines to perform intricate operations. The key differentiator when compared to other manufacturing methods is that machining offers superior dimensional accuracy and surface finish, making it particularly suited for applications that demand high tolerance levels. Moreover, machined metal parts can be produced from a wide range of materials such as aluminum, steel, titanium, and brass, catering to the specific requirements of different industries.

The significance of machined metal parts cannot be overstated, as they are integral to the functionality and reliability of end products. For example, in aerospace, the components must withstand extreme conditions while maintaining lightweight properties. In the medical field, precision is crucial, as it directly impacts patient safety and device efficacy. Thus, understanding the importance of machined metal parts and their manufacturing processes is essential for engineers, designers, and manufacturers to ensure the production of high-quality, reliable components suitable for their applications.

Types of Machining Processes

Machining is a crucial manufacturing process that involves the removal of material from a workpiece to achieve desired geometries and surface finishes. Several key machining processes are commonly employed, each with its unique characteristics and applications. Understanding these processes can significantly enhance decision-making in project planning and execution.

One of the most prevalent machining methods is turning, which primarily uses a lathe to rotate the workpiece against a cutting tool. This process is especially effective for cylindrical parts and is suitable for materials such as metals and plastics. Turning allows for precise control over dimensions and surface finish, making it ideal for producing shafts, pins, and other round components.

Milling is another widely utilized machining process where a rotating cutter removes material from a stationary workpiece. This process can produce a variety of complex shapes and is versatile enough to work with numerous materials, including aluminum, steel, and wood. Milling machines come in various configurations, such as vertical and horizontal, allowing adaptability to different project requirements.

Drilling is specifically aimed at creating holes in a workpiece and is often the first step in more complex machining operations. A drill bit is rotated and pushed into the material, making it suitable for both metals and plastics. The ability to drill holes of various sizes and depths highlights its importance in assembling parts and components.

Lastly, grinding is a finishing process characterized by the use of abrasive wheels to achieve tight tolerances and smooth surface finishes. This process is typically reserved for materials that require a high degree of precision, such as hard steels and ceramics. Grinding is often the final step in producing machined metal parts, ensuring they meet stringent specifications.

Each machining process plays a vital role in the manufacturing of machined metal parts, and understanding their strengths and applications can help in selecting the right approach based on specific project needs.

Materials Used for Machined Metal Parts

Machined metal parts are integral to a wide array of industries, such as automotive, aerospace, and manufacturing, with the selection of material significantly influencing their performance and durability. Four prevalent materials utilized in the production of machined parts include aluminum, stainless steel, brass, and titanium. Each of these materials possesses distinct properties that not only affect the machining process but also dictate the applications for which they are best suited.

Aluminum is favored for its lightweight and corrosion-resistant characteristics, making it an excellent choice for applications requiring reduced weight without compromising strength. Its machinability is notable; aluminum can be easily shaped and cut, leading to lower production costs. However, while aluminum offers substantial advantages, it can be less durable in high-stress environments compared to other metals.

Stainless steel, known for its strength and resistance to oxidation, is widely employed in environments exposed to moisture and chemicals. Its superior strength-to-weight ratio allows for durable components that can endure various conditions. The machining of stainless steel can present challenges due to its hardness, often necessitating specialized tools which may drive up production costs. Despite this, the longevity and reliability of stainless steel parts make them invaluable for critical applications.

Brass is distinguished by its excellent machinability and conductivity, making it ideal for electrical components and fixtures. Its resistance to corrosion enhances its suitability for plumbing and marine applications. However, the softer nature of brass relative to other metals can lead to quicker wear in high-friction scenarios.

Finally, titanium, while more costly, boasts remarkable strength and low density, which makes it indispensable in aerospace and medical applications. Its resistance to high temperatures and corrosion further enhances its appeal, albeit at the expense of a more challenging machining process.

In selecting the appropriate material for machined metal parts, it is crucial to consider these diverse properties, applications, advantages, and potential drawbacks to achieve optimal performance in any given context.

Benefits of Machined Metal Parts

Machined metal parts offer numerous advantages that significantly enhance their use across various industries. One of the primary benefits is the precision and accuracy achieved during the production process. Through advanced machining techniques, such as CNC (Computer Numerical Control) milling and turning, manufacturers can meet tight tolerances, ensuring that the dimensions of the parts conform to exact specifications. This level of precision is crucial for applications where even minute deviations can lead to critical failures.

Another notable advantage is the ability to create complex geometries. Machining processes allow for intricate designs that may be challenging or impossible to manufacture using traditional methods. This versatility makes machined metal parts suitable for a wide range of applications, from aerospace components to automotive parts. The capability to produce intricate shapes enhances design flexibility and innovation, fostering advancements in product development.

Additionally, machined metal parts exhibit improved durability and strength. The materials used in machining, often hardened steels and alloys, provide enhanced mechanical properties compared to other manufacturing methods like casting or forging. This results in components that can withstand extreme conditions, including high temperatures and heavy loads, making them ideal choices for demanding environments.

Furthermore, the surface finishes achieved through machining are superior compared to many other fabrication techniques. CNC machining can yield smooth, polished surfaces that require minimal post-processing, which improves the aesthetic appeal and functionality of the parts. The enhanced surface quality also contributes to better wear resistance and can reduce friction in moving components.

Finally, the efficiency of producing machined metal parts is another vital benefit. Whether manufacturing small batches or large quantities, the scalability of machining processes ensures consistent quality and reduces lead times. As a result, manufacturers can respond swiftly to market demands while maintaining high standards of production.

Applications of Machined Metal Parts

Machined metal parts play a pivotal role across a multitude of industries, signifying their importance in the modern manufacturing ecosystem. One of the most prominent sectors benefiting from these components is the automotive industry. Here, machined metal parts are used extensively for the production of engine components, transmission systems, and various chassis pieces. The precision and reliability of these parts are crucial, as they directly impact vehicle performance and safety, leading manufacturers to demand high-quality machined solutions to ensure optimal functionality.

Another significant industry that relies heavily on machined metal parts is aerospace. In this sector, components must withstand extreme conditions while maintaining structural integrity. Machined parts are utilized in the fabrication of critical elements such as aircraft frames, landing gear, and engine mounts. The stringent regulations imposed on the aerospace industry necessitate precision machining processes, where tolerances are vital for ensuring safety during flight.

The medical industry also represents a key application area for machined metal parts. Devices utilized within healthcare, including surgical instruments, implants, and diagnostic equipment, require components that adhere to strict biocompatibility and precision standards. Machined metal parts are engineered to meet these essential specifications, ensuring reliability and functionality in life-saving medical applications.

Furthermore, the electronics industry employs machined metal parts for various functionalities, such as heat sinks, housings, and mounting brackets. The need for efficient thermal management and structural support in electronic devices highlights the importance of precision machining in this fast-evolving field. As technology advances, the demand for specialized and customized machined metal components continues to grow, underscoring their versatility and critical role across diverse applications.

Quality Control in Machining

Quality control in the machining of metal parts is a critical component that safeguards the integrity and performance of finished products. Effective quality control measures encompass a range of practices and standards that ensure machined parts meet exacting specifications. Among the foremost elements of quality control are dimensional inspections, which are essential in confirming that the machined part adheres to required tolerances and specifications. This process may involve the use of calipers, micrometers, or coordinate measuring machines (CMM) to verify measurements accurately.

In addition to dimensional checks, materials verification is a significant aspect of quality assurance. Ensuring the right materials are used in the machining process helps prevent inconsistencies and failures during application. Techniques such as chemical analysis and mechanical property testing are employed to validate the composition and strength of metals utilized in the manufacturing of parts. This verification process is vital for applications that demand high structural integrity.

Surface finish requirements also play an integral role in quality control. The surface finish of machined parts can significantly influence their performance, particularly in environments where friction, wear, or corrosion is a concern. Specifications regarding roughness, finish, and treatment must be carefully adhered to in order to maximize the durability and functionality of the components. To achieve these standards, processes such as grinding, polishing, and coating may be employed.

Moreover, testing methods such as non-destructive testing (NDT) are essential in quality control protocols. NDT encompasses various techniques—such as ultrasonic testing, magnetic particle inspection, and dye penetrant testing—that allow for the detection of subsurface defects without damaging the part. Employing these methods not only ensures that potential failures are identified early but also enhances the reliability and longevity of the machined metal parts. Collectively, these quality control measures contribute to the production of high-precision machined components necessary in various industries.

Technological Advances in Machining

The machining industry has witnessed significant technological advancements in recent years, transforming traditional manufacturing processes and enhancing the production of machined metal parts. One of the most impactful innovations has been the incorporation of Computer Numerical Control (CNC) machines. These systems allow for precise control of machining tools via computer programming, resulting in extraordinarily accurate components with reduced human error. The ability of CNC machines to produce complex geometries efficiently has fundamentally changed how manufacturers approach design and production.

In addition to CNC technologies, automation has increasingly become a vital aspect of machining operations. Automated systems not only improve the consistency of output but also significantly increase production rates. By integrating robotics into the machining process, manufacturers can reduce labor costs and minimize human intervention, allowing operators to focus on more strategic tasks. Automation also contributes to workplace safety by handling heavy or hazardous components, thereby reducing the risk of workplace accidents.

Another noteworthy advancement in the machining industry is 3D machining, which facilitates the manufacturing of intricate designs and custom components. This technology enhances the possibility of creating lightweight yet robust machined parts, catering to demands in industries such as aerospace, automotive, and medical devices. Furthermore, 3D machining promotes material savings and sustainability, as it allows for the efficient use of raw materials, thus minimizing waste during the production process.

Lastly, the impact of Industry 4.0 cannot be overstated. This paradigm shift toward smart manufacturing encompasses a range of interrelated technologies, including IoT devices, big data analytics, and machine learning. By leveraging these technologies, manufacturers can optimize their machining processes through real-time monitoring, predictive maintenance, and adaptive manufacturing strategies. The integration of these advanced technologies not only enhances the quality of machined parts but also paves the way for a more sustainable and efficient machining landscape.

Challenges in Machining

The machining of metal parts is a highly sophisticated process that, while necessary for precision manufacturing, presents a multitude of challenges. One of the primary issues faced during machining is tool wear, which can significantly affect the quality of the finished product. Over time, cutting tools degrade due to friction and pressure, leading to decreased accuracy and increased surface roughness. To mitigate this, manufacturers can employ advanced materials for cutting tools, such as carbide or ceramics, which offer greater durability and resistance to wear.

Another critical challenge is material waste, which not only impacts production costs but also raises concerns regarding the sustainability of the machining process. When portions of metal are removed during machining, it is essential to manage this waste efficiently. Techniques such as optimizing machining parameters—like speed, feed rate, and depth of cut—can substantially reduce scrap material. Additionally, implementing recycle and reuse practices will contribute to minimizing overall material waste in machining operations.

Achieving precise tolerances is another significant challenge. The demand for tighter tolerances in industries such as aerospace, automotive, and medical devices necessitates meticulously controlled machining processes. Variations in machine conditions, tool performance, and material properties can result in deviations from specified tolerances. To enhance precision, manufacturers are increasingly utilizing computer numerical control (CNC) technologies, which ensure consistent and repeatable results. Furthermore, regular maintenance of machinery can prevent issues that might compromise accuracy.

In summary, while machining metal parts comes with inherent challenges such as tool wear, material waste, and tolerance achievement, these issues can be effectively addressed. Through the adoption of proper planning, the integration of advanced technologies, and best practices within the machining industry, manufacturers can enhance the quality and efficiency of their processes.

Future Trends in Machined Metal Parts

The machined metal parts industry is undergoing significant transformations driven by technological advancements, market demands, and environmental considerations. One prominent trend is the push towards sustainability. With an increasing global focus on eco-friendly practices, manufacturers are adapting their processes to reduce waste and energy consumption. This shift is evident in the adoption of recycling methods and the use of environmentally friendly lubricants, ultimately contributing to a reduced carbon footprint in the production of machined components.

Another notable trend is the increased utilization of new materials. Traditional metals like aluminum and steel are being complemented and sometimes replaced with advanced alloys and composites that offer superior properties, such as enhanced strength-to-weight ratios, corrosion resistance, and improved machinability. This expansion in material options allows engineers and designers to create more innovative and efficient products, ranging from aircraft parts to automotive components. As industries continue to evolve, the demand for specialized materials in machined metal parts is projected to rise.

Furthermore, automation and artificial intelligence are playing a crucial role in the future of machining. The integration of smart technologies is enhancing production efficiency and precision. Automated machining processes reduce human error and streamline operations, while AI algorithms can optimize machining parameters in real-time, contributing to lower production costs and faster turnaround times. These technologies not only improve quality but also provide manufacturers with the agility needed to respond to changing market demands.

In conclusion, the machined metal parts industry is poised for transformative changes shaped by sustainability, new materials, and the integration of automation and AI. Keeping an eye on these trends will be essential for stakeholders to remain competitive and responsive to future challenges and opportunities in this dynamic field.