Introduction to Optical Parts Machining

Optical parts machining is a specialized manufacturing process focused on producing high-precision components integral to a wide range of optical systems. This intricate process involves the shaping and finishing of materials to create optical components such as lenses, prisms, mirrors, and filters. Precision is paramount in optical parts machining, as even minor deviations can significantly impact the performance of the optical system in which these components are utilized.

The significance of optical parts machining extends across various industries, with telecommunications, medical devices, and consumer electronics being some of the most notable fields. In telecommunications, machined optical parts play a crucial role in fiber optic systems, where they facilitate data transmission over long distances with minimal signal loss. The accuracy of optical components directly influences the efficiency and reliability of communication networks, making high-quality machining essential.

Similarly, in the medical industry, optical components are utilized in devices such as endoscopes and imaging systems. The precision achieved through optical parts machining ensures that these devices provide accurate diagnostics and effective treatments. Furthermore, consumer electronics continue to evolve with the inclusion of advanced optical technologies in cameras, screens, and augmented reality devices, necessitating superior optical parts that can be produced through meticulous machining processes.

Different types of optical components can be manufactured, utilizing various materials, including glass, plastics, and specialized coatings to enhance reflectivity and transmissivity. The manufacturing of these components involves advanced techniques such as grinding, polishing, and coating, all of which require a keen attention to detail and experience. As industries continue to advance, optical parts machining remains a cornerstone of innovation, pushing the boundaries of what is possible in optical technology.

The Materials Used in Optical Parts Machining

Optical parts machining involves a variety of materials, each selected for their unique properties and suitability for specific applications. Among the most commonly utilized materials are glass, plastics, and crystalline substances. These materials are chosen based on essential characteristics, such as refractive index, durability, and ease of machining, which play crucial roles in the performance of optical devices.

Glass, particularly optical glass, is one of the most widely used materials in the machining of optical components. Its excellent optical clarity and high thermal stability make it ideal for lenses and other optical elements. The controllable refractive index of glass allows for the precise design of optical systems. However, the machining of glass presents challenges due to its brittleness, which can cause chips and fractures during fabrication. To mitigate these risks, advanced machining techniques such as diamond turning and ultra-precision grinding are employed.

Plastics, such as polycarbonate and acrylic, have gained popularity in optical machining due to their lightweight nature and resistance to impact. These materials provide flexibility and can be processed more readily than glass, resulting in reduced manufacturing costs. While their optical clarity is often sufficient for many applications, they typically have a lower refractive index and can be more susceptible to scratching and environmental degradation. To address these issues, coatings that enhance durability and reduce reflections are frequently applied.

Crystalline materials, such as quartz and sapphire, are used in specialized optical applications where extreme durability and thermal stability are required. These materials possess unique optical properties that make them suitable for high-precision optics and sensors. However, the machining of crystalline materials can be challenging due to their hardness, necessitating the use of specialized tools and techniques to achieve optimal results.

Machining Methods for Optical Components

The production of optical components necessitates precision and accuracy, qualities that are achieved through various machining methods. Among those, grinding, polishing, and CNC machining are the predominant techniques utilized for creating high-quality optical parts.

Grinding is a material removal process that utilizes an abrasive wheel to shape optical components. This method is particularly effective in achieving a desired dimension and surface finish, making it ideal for the initial shaping of glass or other optical materials. One of the key advantages of grinding is its ability to remove material quickly while maintaining precise tolerances. However, it can also lead to surface imperfections if not carefully controlled, thus requiring subsequent processes to achieve the final finish.

Polishing, on the other hand, focuses on enhancing the surface finish of optical components after the grinding phase. This method employs fine abrasives and a suitable lubricant to smooth the surface, ultimately resulting in a high degree of clarity essential for optical applications. While polishing is crucial for achieving the desired optical quality, it is a time-consuming process that requires skilled operators to monitor and adjust parameters to prevent defects. The effectiveness of polishing significantly impacts the performance of optical systems, emphasizing its importance in the machining workflow.

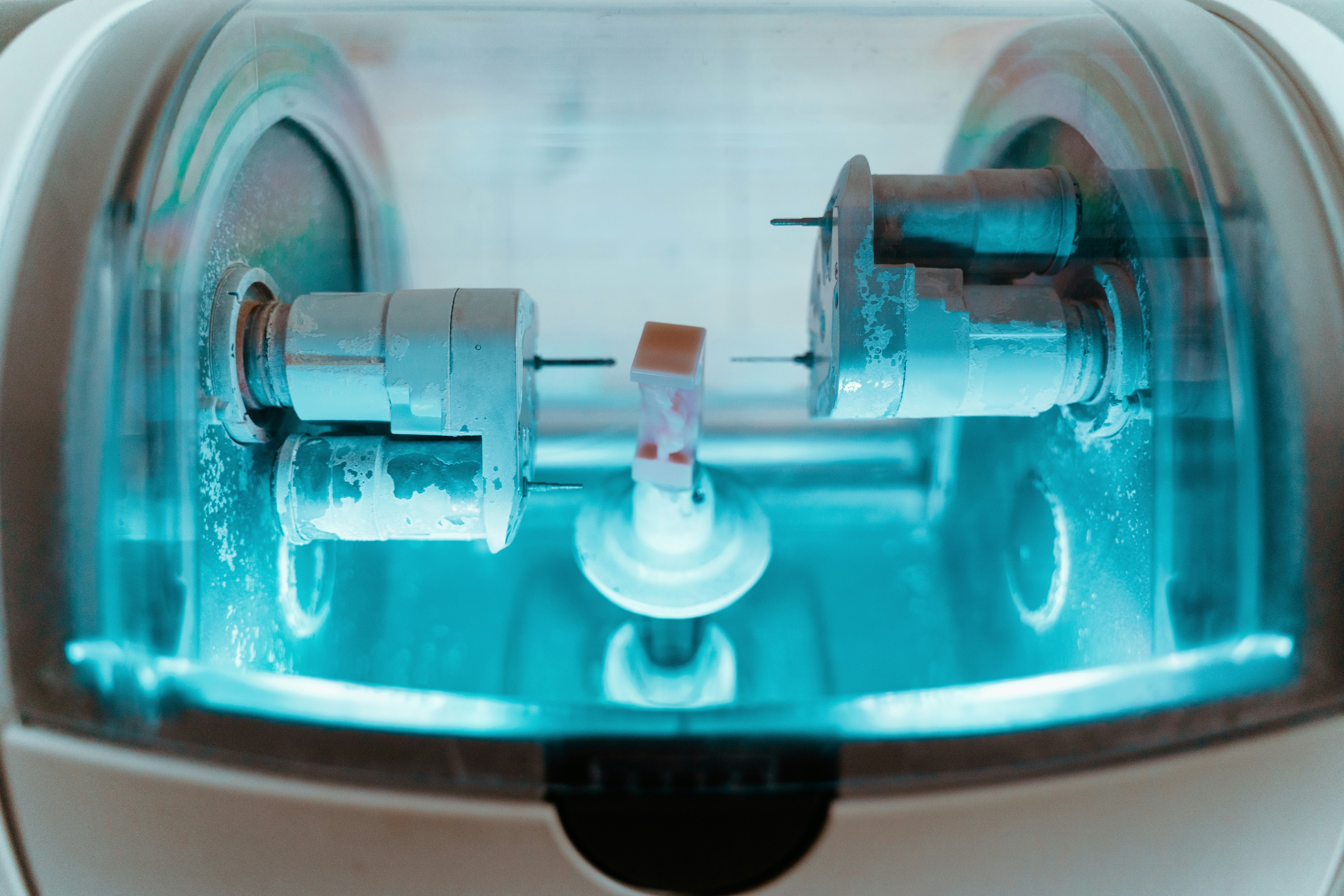

Lastly, CNC machining has emerged as a game-changer in the production of optical parts. This computer-controlled method allows for the precise shaping and finishing of components with high repeatability and minimal human error. One of the most significant advantages of CNC machining is its ability to produce complex geometries with tight tolerances, catering to the specific requirements of advanced optical systems. However, the initial setup costs and programming complexity can be potential limitations for smaller operations.

In summary, each machining method—grinding, polishing, and CNC machining—offers unique advantages and challenges that contribute to the final quality of optical parts. Selecting the appropriate method depends on the specific requirements of the optical application, necessitating a careful assessment of each technique’s capabilities and limitations.

The Role of Technology in Optical Parts Machining

Advancements in technology have significantly transformed the field of optical parts machining, enhancing precision, efficiency, and productivity. One of the critical developments is the integration of computer-aided design (CAD) software, which allows engineers and designers to create precise digital models of optical components. This innovation streamlines the initial design process, enabling a more accurate representation of the intended product and facilitating adjustments before physical production begins.

Additionally, machine automation has revolutionized the machining processes involved in producing optical parts. Automated machinery equipped with advanced control systems can carry out complex manufacturing tasks with a level of speed and consistency that surpasses traditional methods. This level of automation not only reduces human error but also enables manufacturers to operate at a larger scale, thereby increasing overall production capacity. The precision achieved through automation is particularly crucial for optical components, where even minor deviations can significantly impact functionality.

The rise of artificial intelligence (AI) is another technological advancement affecting the machining of optical parts. AI algorithms can analyze production data in real-time to optimize machining parameters, predict maintenance needs, and enhance quality control measures. This integration of AI into the manufacturing process results in reduced downtime, lower costs, and improved product quality, all essential factors in the competitive optical components market.

Emerging technologies, such as 3D printing, are poised to influence the future of optical parts manufacturing further. This innovative approach enables the production of intricate optical geometries that were previously difficult or impossible to achieve with conventional machining techniques. As 3D printing continues to evolve, it is expected to facilitate rapid prototyping and customization of optical components, allowing manufacturers to meet specific client needs more effectively.

Quality Control in Optical Parts Machining

Quality control is a paramount concern in the manufacturing of optical components, where precision and accuracy are non-negotiable. The integrity of optical parts directly impacts their performance in various applications, necessitating robust inspection methods and quality assurance processes. In this regard, advanced measurement techniques play a crucial role in ensuring that optical surfaces conform to stringent specifications.

One of the most significant techniques employed in the quality control of optical parts is interferometry. This method leverages the principles of light interference to detect surface irregularities on optical components. By comparing the test surface to an ideal reference surface, interferometry can quantify deviations with remarkable precision. This capability makes it an essential tool for manufacturers to ensure that their optical components maintain the required flatness and surface quality, which are vital for optimal functionality.

Another important measurement technique is surface profilometry, which provides detailed information about the topography of the optical surfaces. Using either contact or non-contact methods, surface profilometers capture the roughness and texture of the surface being analyzed. This data is critical not only for assessing the quality of the optical parts but also for informing manufacturing processes to minimize defects in future productions.

Compliance with industry standards and certifications further bolsters the quality assurance processes in optical parts machining. Adhering to recognized standards, such as ISO 10110 for optical elements or ISO 9001 for quality management systems, ensures that the manufacturing processes consistently meet customer expectations and regulatory requirements. Certification bodies often conduct audits and assessments, providing a level of assurance that the optical components manufactured are reliable and meet the rigorous demands of various applications.

Challenges in Optical Parts Machining

Optical parts machining involves a variety of challenges that manufacturers must navigate to produce high-quality optical components. One of the most significant issues encountered is material brittleness. Materials commonly used in optical machining, such as glass and certain types of ceramics, are often brittle. This brittleness can lead to chipping, cracking, or even complete breakage during machining processes. To mitigate these risks, manufacturers must employ precise machining techniques, such as employing slower feed rates and using cooled tools to minimize heat generation and reduce stress on the material.

Another common challenge is maintaining dimensional tolerances. Optical components frequently require tight tolerances to ensure proper alignment and functionality within optical systems. Achieving these tolerances is essential but can be difficult due to the nature of the materials and the complexities of the machining process. Utilization of advanced tooling, rigorous process controls, and regular calibration of machines can drastically improve the precision of machined parts. Implementing statistical process control can also help in monitoring the machining process and ensuring dimensional accuracy is consistently achieved.

Surface quality is a further critical concern in optical parts machining. Optical components must often have exceptionally smooth surfaces to prevent scattering of light and ensure optimal performance. Achieving a high surface finish typically requires additional processes such as polishing, which can add complexity and time to the manufacturing cycle. Employing appropriate abrasives and polishing techniques, along with proper machine settings, can greatly enhance surface quality while minimizing the risk of defects. By focusing on these key challenges—material brittleness, dimensional tolerances, and surface finish—manufacturers can develop effective strategies that ensure the production of high-quality optical components while optimizing efficiency in the machining process.

Applications of Machined Optical Parts

Machined optical parts serve a crucial role across various industries, making their applications diverse and far-reaching. One of the most prevalent uses of these components can be seen in the production of lenses for cameras and eyewear. For cameras, precision-crafted lenses are essential for capturing sharp and vibrant images, where even minute imperfections can affect the overall quality. Similarly, in eyewear, lenses must be shaped with the utmost accuracy to ensure optimal vision correction. This showcases how optical parts machining directly contributes to both artistic expression in photography and clarity in personal vision.

Another significant application of machined optical parts is found in mirrors used within optical instruments. These mirrors must be manufactured to exacting standards to achieve the required reflectivity and optical performance. In telescopes and microscopes, for example, precision mirrors enhance the ability to observe distant celestial bodies or minute biological specimens. This highlights the critical nature of optical parts machining in fields such as astronomy and biology, underscoring the importance of accuracy and reliability.

Furthermore, machined optical parts are integral to the development of components for lasers and fiber optics. Lasers rely on various optical elements to focus and direct light, essential for applications ranging from industrial cutting tools to medical devices. In fiber optics, precision-engineered connectors and lenses are vital to ensuring effective light transmission over long distances. This role of optical parts machining has catalyzed advancements in communication technologies and health care, making it a foundational element of modern innovation.

In summary, the applications of machined optical parts are vast, significantly impacting industries such as photography, eyecare, astronomy, and telecommunications. The precision involved in the manufacturing of these components is indispensable for the functionality and advancement of numerous technological fields.

The Future of Optical Parts Machining

The field of optical parts machining is poised for significant advancements as new technologies emerge and industry demands evolve. One of the primary trends anticipated in the near future is the integration of advanced materials in the manufacturing process. Traditional materials, such as glass and plastic, will likely be joined by innovative composites and ceramics, which could improve the performance and durability of optical components. These new materials may enhance optical clarity, thermal stability, and resistance to wear, which will ultimately expand the applications for which optical parts can be used.

Furthermore, automation is projected to play a crucial role in the future of optical parts machining. With the increasing incorporation of robotic systems and artificial intelligence, manufacturers may experience enhanced precision, consistency, and efficiency in their production processes. Automated machining regulations will likely facilitate the mass production of complex optical elements, thereby reducing lead times and lowering costs. Additionally, real-time monitoring systems can help maintain quality control throughout the manufacturing stages, ensuring that products meet the stringent requirements that the optical industry demands.

Sustainability practices are also becoming increasingly relevant in optical parts machining. As global awareness of environmental issues heightens, industry players are expected to adopt greener practices. This includes implementing recycling methods for excess materials, reducing waste throughout the manufacturing process, and utilizing energy-efficient machines. Such sustainable approaches not only benefit the environment but may also enhance a company’s reputation and improve customer loyalty.

As consumer demands shift toward more innovative and sustainable products, the optical parts machining industry must evolve accordingly. Continuous innovation will be crucial in responding to these demands, whether through advancements in technology, materials, or practices. By embracing these trends, the sector can secure a competitive edge and address the dynamic needs of the marketplace effectively.

Conclusion

In this comprehensive guide, we have explored the intricacies of optical parts machining, illuminating its vital role in various modern technological applications. Through a thorough examination of the processes involved, we have established that optical machining is not merely a manufacturing technique but a critical contributor to precision in industries ranging from telecommunications to medical devices.

We have discussed essential methodologies such as diamond turning and precision grinding, highlighting how these methods contribute to the production of high-quality optical components. The importance of these processes becomes evident when considering the precise specifications required for components that serve in advanced optical systems. Moreover, we emphasized that continuous innovation in optical parts machining is paramount. Advances in technology and materials can significantly enhance the capabilities and performance of optical products, thus meeting the escalating demands of various fields.

The quality of manufacturing processes in optical machining cannot be overstated. Quality assurance measures, including thorough inspections and adherence to stringent standards, are essential to ensure that the produced components maintain the requisite specifications and performance criteria. As industries increasingly rely on optics, the need for precise and reliable optical parts becomes even more crucial.

In conclusion, the field of optical parts machining stands at the forefront of modern technology, influencing a variety of applications that shape our daily lives and professional environments. We encourage further exploration of this discipline, as understanding its principles will not only enhance awareness but also foster advancements that may lead to groundbreaking innovations in numerous sectors. As technology continues to evolve, so too should our exploration and knowledge of the critical processes that underpin it.