Introduction to Swiss CNC Machining

Swiss CNC machining, a sophisticated manufacturing technique, originated in the late 19th century in Switzerland. This innovative approach was developed to meet the demands of the watchmaking industry, where precision and accuracy are paramount. The unique capabilities of Swiss CNC machining have since evolved, enabling it to meet a wide array of industrial needs. Unlike traditional machining methods, this technique utilizes a sliding headstock that allows the material to be fed through the lathe, allowing for the efficient production of intricate components.

One of the standout characteristics of Swiss machining is its ability to create highly complex and precise parts through a process characterized by multiple axes of movement. Typically, Swiss CNC lathes operate on a minimum of three axes—longitudinal, cross, and vertical—but many modern machines can function on five or more axes. This multi-axis capability allows manufacturers to produce intricate geometries and tight tolerances that would be challenging to achieve with conventional machining techniques.

The range of industries benefiting from Swiss CNC machining is extensive, with significant applications in the aerospace, medical, and automotive sectors. In aerospace, the need for lightweight yet durable components aligns perfectly with the capabilities of Swiss machining, allowing for the production of complex parts that meet stringent safety and performance standards. Meanwhile, the medical field relies on the high precision offered by this technology to manufacture surgical instruments and implants with exceptional accuracy. In the automotive industry, Swiss machining is utilized for producing essential components that require tight tolerances to ensure optimal vehicle performance.

Overall, Swiss CNC machining represents a pinnacle of precision engineering, continually adapting to advance manufacturing technologies. Its origins in watchmaking have set the foundation for a versatile technique with far-reaching implications across various sectors, thus solidifying its importance in the contemporary manufacturing landscape.

Understanding the Process of Swiss CNC Machining

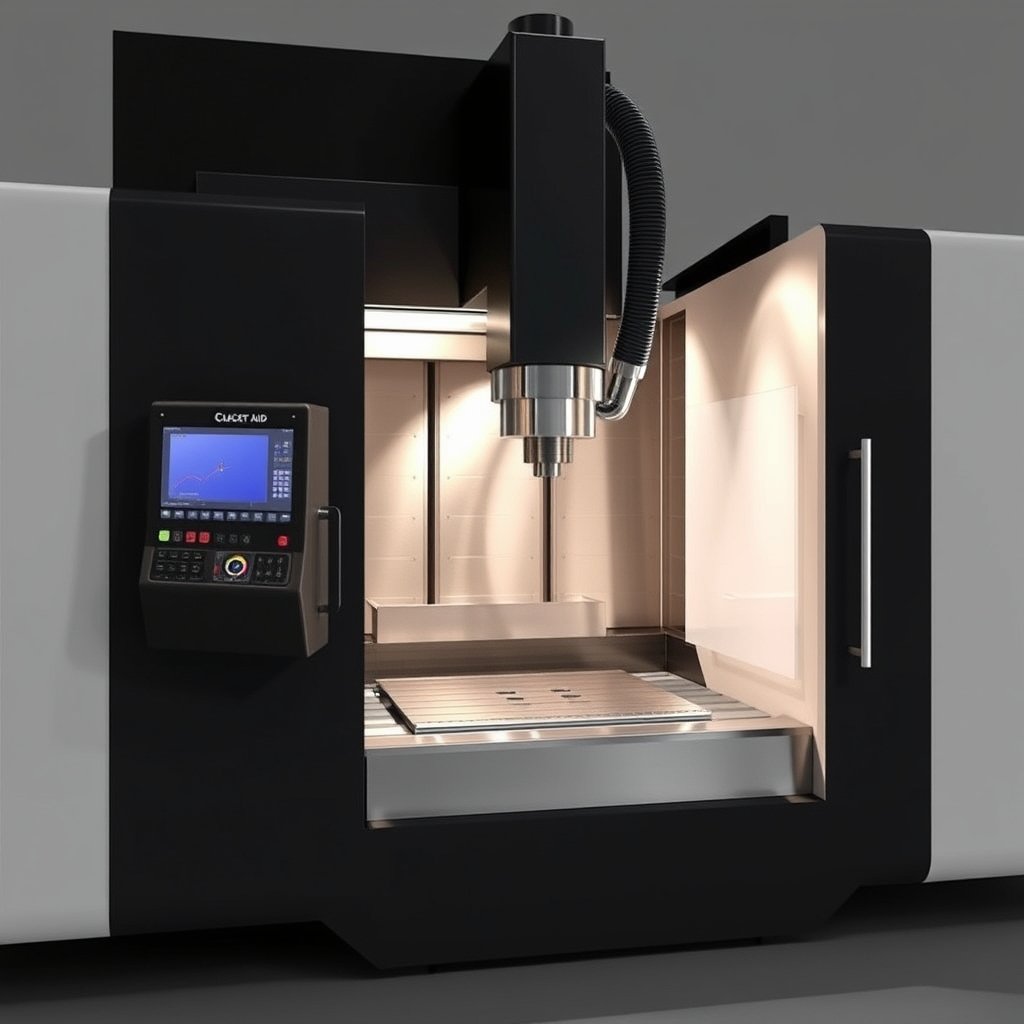

Swiss CNC machining, renowned for its high precision and efficiency, operates through a series of intricate processes that transform raw materials into meticulously crafted finished components. At the heart of this process lies the CNC lathe, specifically designed for precision turning operations. The CNC lathe incorporates several components, such as the spindle, tool holder, and workpiece holder, all of which play crucial roles in ensuring accuracy and stability during machining.

The spindle is the component that rotates the workpiece, allowing for the necessary turning and shaping. Attached to the spindle, the tool holder securely houses various cutting tools, which can be swapped out depending on the required operation. This flexibility enhances the machining process, as multiple tools can be accessed without needing to halt production. The workpiece is meticulously positioned, utilizing a sliding mechanism that facilitates movement along multiple axes.

In Swiss CNC machining, the positioning of both the workpiece and tools is governed by computer numerical control (CNC) technology. This technology ensures that movements are executed with extreme precision, guided by pre-programmed instructions. This capability allows for the creation of complex geometries and tight tolerances, essential in industries such as aerospace and medical device manufacturing.

Moreover, cooling systems are integral to Swiss machining, helping maintain optimal temperatures during the cutting process. These systems typically utilize a combination of coolant fluids that reduce friction and heat, thereby prolonging tool life and enhancing the quality of the finished product. The interplay of these components and systems underscores the advanced technology of Swiss CNC machining, showcasing its role in modern manufacturing.

Advantages of Swiss CNC Machining

Swiss CNC machining represents a significant advancement in the field of precision engineering, offering numerous advantages over traditional machining methods. One of the most notable benefits is the increased precision and accuracy that Swiss CNC machines provide. These machines utilize a unique sliding headstock design, which allows for the production of highly detailed components with minimal variability, even at extremely tight tolerances. This level of precision is essential in industries such as aerospace, automotive, and medical, where even the slightest deviation can lead to significant complications.

In addition to precision, Swiss CNC machining offers enhanced production speed. The continuous feed and automatic tool-changing capabilities of these machines enable them to work on multiple components simultaneously, significantly reducing cycle times. This efficiency translates to higher output without compromising quality, making Swiss machining an attractive option for manufacturers looking to meet increasing demands for high-volume production while maintaining stringent standards.

Furthermore, Swiss CNC machining contributes to reduced material waste. Traditional machining techniques often involve excessive material removal, leading to increased scrap. Conversely, Swiss machining is characterized by its efficient use of materials, as it typically involves the use of bar stock, which allows for near-net shape production. This approach not only conserves materials but also reduces costs associated with waste disposal and procurement.

Another advantage is the capability of Swiss CNC machining to produce complex geometries and intricate designs that are challenging to achieve with conventional methods. The versatility of these machines allows for the creation of intricate patterns and features within a single setup, optimizing the Machining process and further contributing to efficiency. Overall, the benefits of Swiss CNC machining make it a pivotal technology in the realm of precision engineering, positioning itself as a superior choice for various manufacturing applications.

Common Applications of Swiss CNC Machining

Swiss CNC machining has become a cornerstone in various industries due to its unmatched precision and adaptability. One prominent sector benefiting from this technology is aerospace. In aerospace engineering, components such as fuel injectors, turbine blades, and other intricate parts require a high level of accuracy and consistency. Swiss machining provides the ability to produce these components with tight tolerances, ensuring safety and efficiency in flight operations.

Another crucial application of Swiss CNC machining is in the manufacture of medical devices. The medical sector demands components that not only meet stringent regulatory standards but also exhibit exceptional quality. Examples include surgical instruments, implants, and diagnostic equipment, all of which often require complex geometries and flawless surface finishes. Companies in this industry have increasingly turned to Swiss machining to fulfill these needs, resulting in improved patient outcomes and operational efficiencies.

The automotive industry also plays a significant role in utilizing Swiss CNC machining. Precision-engineered parts such as valve stems, transmission components, and fuel systems are essential for vehicle performance and safety. Swiss machining’s capability to produce small batches of highly complex parts makes it an ideal choice for automotive manufacturers aiming to innovate while minimizing production costs.

Case studies illustrating the successful implementations of Swiss CNC machining highlight its versatility. For instance, a company specializing in medical devices achieved a 30% reduction in production time by integrating Swiss CNC technology into its manufacturing process. Similarly, an aerospace component manufacturer reported enhanced quality control and reduced waste through the precision capabilities of Swiss machining. These examples underscore the critical role that Swiss CNC machining plays across various sectors, driving progress and quality in modern manufacturing.

Materials Used in Swiss CNC Machining

Swiss CNC machining is renowned for its ability to achieve precision and detail in manufacturing complex geometries. The choice of materials plays a significant role in the performance of the machining process. Metals such as aluminum, brass, and stainless steel are commonly used due to their favorable machinability and structural properties. Each of these materials possesses unique characteristics that influence the machining operations and final product quality.

Aluminum, for instance, is lightweight yet strong, making it an ideal choice for industries that prioritize reducing weight without sacrificing structural integrity. Its excellent thermal conductivity also enables efficient heat dissipation during machining, contributing to longer tool life. Brass, on the other hand, is favored for applications requiring corrosion resistance and aesthetic finishes. Its machinability is superior, allowing for intricate designs with a smooth surface finish, often utilized in plumbing fittings and decorative items.

Stainless steel is another widely used material in Swiss CNC machining, recognized for its high resistance to corrosion and heat. While it presents challenges due to its toughness, advancements in tooling and machining strategies have made it manageable, allowing for the production of durable components suitable for the medical and aerospace industries.

Besides metals, various plastics are also used in Swiss CNC machining, such as nylon, polycarbonate, and acrylic. These materials offer versatility and can be ideal for producing lightweight, non-conductive components. The selection of the right material is crucial for successful machining outcomes; it directly affects factors such as tool wear, cutting speeds, and overall production costs.

When selecting a material for specific applications, manufacturers should consider factors such as mechanical properties, environmental conditions, and processing methods. Understanding the attributes of each material can facilitate informed decisions, ultimately enhancing production efficiency in Swiss CNC machining.

Choosing a Swiss CNC Machining Service Provider

When selecting a Swiss CNC machining service provider, it is essential to carefully consider several key factors to ensure you partner with a reputable company capable of meeting your precision engineering requirements. One of the primary factors is the provider’s experience in the industry. Companies with a robust history in Swiss CNC machining are more likely to possess the expertise needed to deliver high-quality results consistently. Look for service providers that have a proven track record and a portfolio showcasing their previously completed projects.

Another important factor is the technological capabilities of the provider. Swiss CNC machining requires advanced machinery and software, so it is crucial to assess whether the service provider has modern equipment that can handle your specific production needs. Inquire about the types of materials they can work with and the precision tolerances they can achieve. A provider that stays updated with the latest technology is often better equipped to deliver quality services.

Certification and compliance with industry standards also play a significant role in choosing a Swiss CNC machining partner. Ensure that the service provider has the necessary certifications, such as ISO 9001, which indicates a commitment to quality management systems. This can serve as an assurance of their dedication to maintaining high standards in their operations.

Additionally, customer reviews can provide valuable insights into the reliability and quality of a machining service provider. Look for testimonials from past clients to gauge their satisfaction and the overall performance of the vendor. It is also advisable to ask potential providers pertinent questions, such as their lead times, pricing structure, and policies regarding quality control.

Lastly, be vigilant for red flags such as lack of transparency about processes, inflated pricing without justifications, and poor communication skills. Taking the time to thoroughly evaluate these factors will help ensure that your selected Swiss CNC machining service provider aligns with your expectations and project requirements.

Trends and Innovations in Swiss CNC Machining

Swiss CNC machining has experienced significant transformation in recent years, primarily driven by technological advancements and emerging trends. One of the most notable shifts is the integration of automation within the machining process. Automating tasks not only enhances efficiency but also reduces human error, enabling manufacturers to achieve greater precision and consistency. Automated systems can manage repetitive tasks, allowing skilled operators to focus on more complex functions that require critical thinking and expertise.

Another prominent trend is the incorporation of artificial intelligence (AI) into Swiss CNC machining operations. AI technologies facilitate smarter decision-making throughout the production cycle. For instance, predictive maintenance powered by AI algorithms can anticipate equipment failures before they occur, minimizing downtime. Additionally, machine learning can optimize machining parameters in real-time, which can significantly improve product quality and production speed. As data analytics becomes more sophisticated, the ability to analyze trends and adapt machining processes accordingly will create a competitive advantage for manufacturers.

Moreover, the development and utilization of advanced materials play a crucial role in the evolution of Swiss CNC machining. Manufacturers can now work with tougher, lighter materials that present unique challenges and opportunities in machining processes. These materials often require specialized cutting tools and techniques, pushing the envelope for precision engineering. As companies explore these advanced substances, they may find new applications and markets, further driving innovation in the industry.

Looking ahead, the future of Swiss CNC machining appears promising, with continuous advancements set to reshape the landscape. Ongoing research and development initiatives will likely introduce even more sophisticated technologies aimed at enhancing operational efficiency and precision. As these trends unfold, staying informed about the latest innovations will be essential for businesses aiming to maintain a competitive edge in precision engineering.

Challenges in Swiss CNC Machining

Swiss CNC machining offers numerous benefits such as precision and efficiency, yet it is not without its challenges. One prevalent issue is the high setup costs associated with this technology. Initial investment in Swiss CNC machinery can be substantial, often requiring expensive equipment and tooling to ensure optimal performance. This financial barrier can deter smaller manufacturers from adopting this advanced machining method, thus limiting their competitive edge in precision engineering.

Another significant challenge is the complexity of programming Swiss CNC machines. Unlike traditional machining, where operations may be more straightforward, Swiss CNC involves intricate tool paths and configurations. The programming demands a thorough understanding of both the software and the machine, necessitating training and experience. As a result, companies may face difficulties in finding qualified personnel who can effectively program and operate Swiss CNC machinery, potentially leading to production delays and inefficiencies.

The need for skilled operators further compounds these challenges in Swiss CNC machining. These operators must possess a wide range of technical competencies, from interpreting engineering drawings to troubleshooting complex issues that may arise during the machining process. Without a strong base of skilled labor, maintaining the high-quality production standards that Swiss CNC machining is known for can be precarious.

To mitigate these challenges, companies can implement various strategies. Investing in employee training programs can cultivate a knowledgeable workforce capable of navigating the complexities of Swiss CNC machining. Additionally, organizations may benefit from collaborating with experienced engineers or consultants who can streamline the setup and programming processes. Adopting best practices in machine maintenance can also enhance efficiency, thereby reducing downtime and production costs. By addressing these obstacles, manufacturers can harness the full potential of Swiss CNC technology, ensuring sustained quality and precision in their operations.

Conclusion: The Future of Swiss CNC Machining

Swiss CNC machining has emerged as a cornerstone of modern precision engineering, playing an integral role in numerous industries, including aerospace, automotive, and healthcare. The unique capabilities of Swiss machining, characterized by its ability to produce complex geometries and achieve high tolerances, have positioned it as a preferred method for manufacturers aiming to meet ever-growing demands for precision, efficiency, and innovation. As we look to the future, several trends are poised to shape the evolution of Swiss CNC machining.

One significant factor influencing the future of Swiss CNC machining is the continual advancement of technology. With the integration of artificial intelligence and machine learning into manufacturing processes, companies can expect increased automation and improved workflow efficiency. This technological integration will allow Swiss CNC machines to optimize production schedules, reduce downtime, and maintain high-quality standards with minimal human intervention.

Furthermore, the globalization of supply chains and the increasing emphasis on sustainability are setting the stage for Swiss CNC machining to adapt and evolve. Manufacturers are seeking ways to minimize waste and energy consumption, and Swiss machines, known for their precise material management, align well with these sustainability goals. The ongoing commitment to reducing the environmental impact of machining processes is likely to lead to innovations that enhance the resource efficiency of Swiss CNC operations.

In addition, the demand for customization and short production runs is growing, driven by shifts in consumer preferences and market dynamics. Swiss CNC machining, with its flexibility to rapidly reconfigure setups for varied specifications, will continue to be essential in meeting these heightened expectations for tailored solutions.

In conclusion, the future of Swiss CNC machining appears robust, marked by technological advancements, heightened sustainability efforts, and an adaptive approach to meet dynamic market needs. As the industry embraces these changes, Swiss machining will undeniably remain at the forefront of precision engineering, setting the standard for excellence across multiple sectors.