Understanding CNC Machining

CNC, or Computer Numerical Control machining, is a revolutionary manufacturing process that utilizes computer systems to control machine tools. CNC machining is integral across various industries, particularly in applications requiring high precision and accuracy, such as the medical field. At its core, CNC machining involves the automation of machine tools through computerized commands, which allows for detailed precision and uniformity in production. The CNC system interprets a computer-aided design (CAD) file, converting it into machine language commands that guide the tools through their operations.

The CNC machining process typically involves several steps. Initially, a design is created and then translated into a code format, usually G-code. This format informs the CNC machine about how to execute the necessary tasks, including tool paths, speeds, and movements. The machine then carries out the operation on raw materials using various tools, such as lathes, mills, and routers, resulting in intricately crafted components.

One of the key advantages of CNC machining lies in its ability to produce complex geometries and detailed components at scale without compromising precision. The technology eliminates many of the human errors associated with traditional machining, allowing for consistent results across multiple productions. In the medical industry, where components are often subject to stringent regulations regarding accuracy and reliability, the benefits of CNC machining become even more pronounced. Components such as surgical instruments, implants, and prosthetics must adhere to exacting tolerances to ensure patient safety and efficacy.

Furthermore, CNC machining can accommodate a variety of materials, including metals, plastics, and composites, making it highly versatile. As such, the application of CNC technology in the medical industry enhances not only manufacturing capabilities but also contributes to improving healthcare outcomes through the delivery of reliable, high-quality components.

Importance of Precision in Medical Devices

Precision is a cornerstone of the medical industry, particularly when it comes to the manufacturing of medical devices. The significance of precision lies not only in the technical specifications but in its broader implications for device performance, patient safety, and adherence to regulatory standards. In a field where errors can lead to dire consequences, the role of accurately engineered components cannot be overstated.

When medical devices are manufactured with precision CNC components, they exhibit improved functionality and reliability. For instance, surgical instruments that maintain strict tolerances are crucial during operations, where even a minuscule error can compromise the outcome. According to a study published in the Journal of Medical Devices, devices with deviations in precision were linked to a 20% increase in surgical complications. Such statistics highlight the profound impact that precision has on patient outcomes, underscoring the necessity for rigorous quality control and sophisticated manufacturing techniques.

Moreover, the importance of precision is magnified by regulatory requirements set forth by bodies such as the FDA. Compliance with these standards is non-negotiable, as it ensures that medical devices meet specific safety and effectiveness criteria. For instance, a precision failure in manufacturing could lead to devices being recalled, causing significant financial implications and undermining public trust in medical innovations. The industry has witnessed high-profile recalls, where minor inaccuracies led to unsafe devices being distributed, emphasizing the need for stringent adherence to precise manufacturing practices.

In sum, precision within the medical device sector is of utmost importance. It influences not just the performance of devices but also the overall safety and efficacy for patients. Continuous improvements in CNC technology have allowed for better precision, thus enhancing the quality of healthcare outcomes and ultimately saving lives.

Common CNC Components Used in Medical Devices

In the medical industry, precision and reliability are paramount, with CNC (Computer Numerical Control) components playing a crucial role in the fabrication of medical devices. These components are meticulously manufactured to meet stringent regulatory standards and are essential in ensuring the functionality and longevity of surgical instruments, implants, and diagnostic equipment.

Among the most commonly utilized CNC components in medical devices are surgical instruments. These instruments often include tools such as scalpels, forceps, and scissors, which are critical for performing precise surgical procedures. Typically crafted from medical-grade stainless steel or titanium, these materials confer durability and resistance to corrosion, thereby enhancing the longevity of the instruments. The meticulous machining processes involved in producing these components allow for sharp, precise edges and ergonomic designs, instrumental for successful medical outcomes.

Another essential category of CNC components found in the medical field includes implants. Components such as joint replacements and dental implants require high precision due to their direct interaction with biological tissues. These implants are often manufactured from specialized materials like biocompatible polymers and alloys, which not only provide strength and durability but also minimize the risk of adverse reactions in the body. The use of CNC technology in their production ensures that these implants can be tailored to achieve optimal fit and function.

Furthermore, diagnostic equipment is another vital category reliant on precision CNC components. Devices such as MRI machines, ultrasound equipment, and blood analysis instruments rely on finely tuned mechanical parts to deliver accurate results. Components crafted with intricate precision from high-quality materials help sustain the accuracy and reliability of these diagnostic tools, promoting better patient care outcomes.

The Manufacturing Process of Medical CNC Components

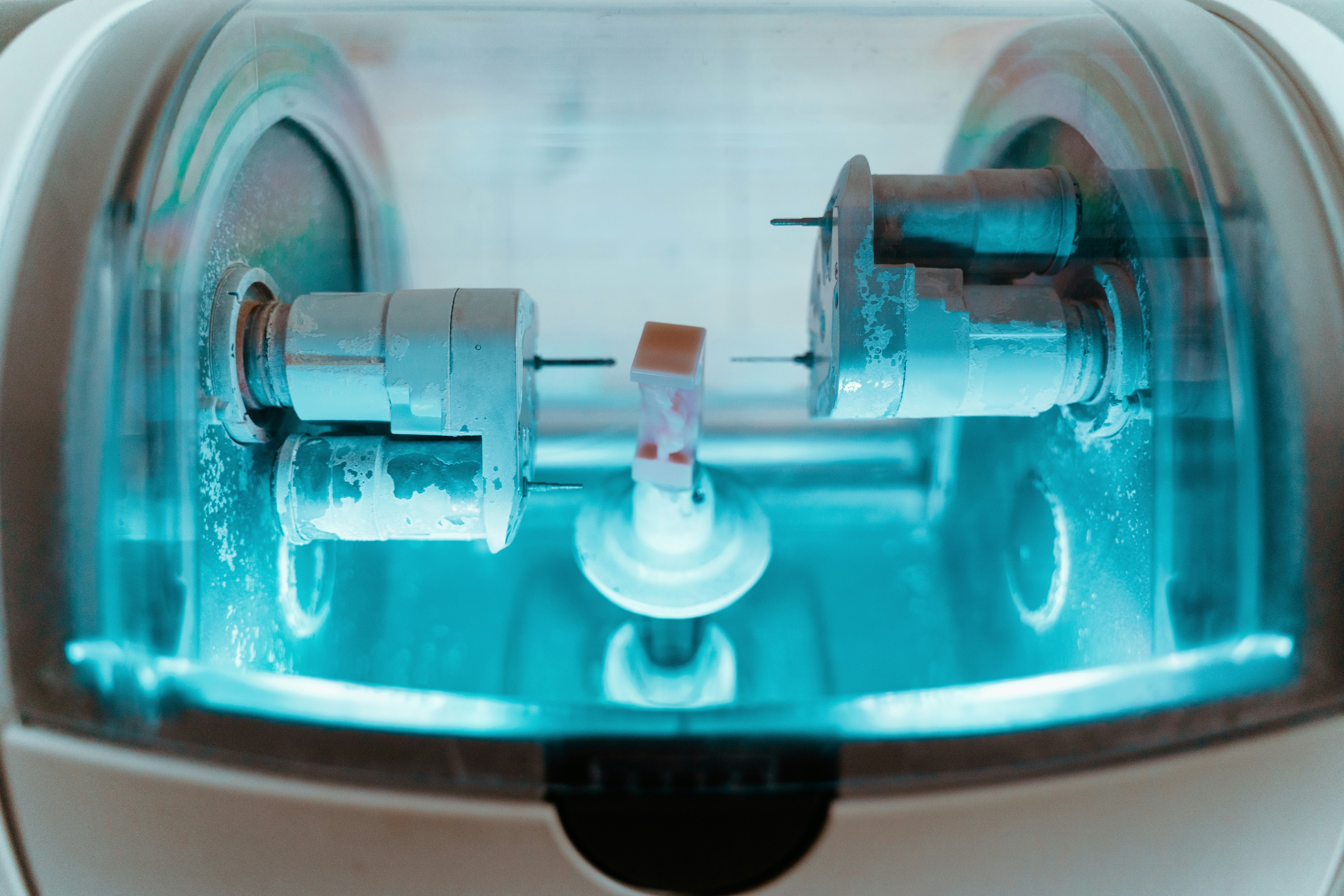

The manufacturing of CNC components for the medical industry involves a meticulous and multi-faceted process, ensuring that each component meets stringent health standards and performs reliably in critical applications. Initially, the journey begins with the design phase, where designers and engineers collaborate to develop detailed specifications tailored to specific medical needs. Using advanced CAD software, prototypes of the components are created, allowing teams to visualize and test the functionality before moving forward. This phase is crucial, as it sets the foundation for precision manufacturing.

Once the designs are finalized, the next step involves machining, which employs CNC (Computer Numerical Control) technology to produce the components from various materials such as titanium, stainless steel, or specialized polymers. CNC machines utilize precise movements to cut, mill, and grind materials into exact shapes and specifications. Each operation is carefully programmed to ensure that the components are manufactured according to the predefined tolerances necessary for medical applications. This aspect of manufacturing is paramount, as even the smallest deviation can lead to significant complications in medical devices.

After machining, the components undergo finishing processes that enhance their functionality and biocompatibility. Techniques such as polishing, anodizing, and coating are often employed to improve surface characteristics and protect against corrosion or biological reactions. Once these final touches are applied, rigorous quality control inspections are conducted. These inspections include dimensional checks, visual assessments, and functional tests to ensure that every piece adheres to stringent medical industry regulations and standards.

Through a combination of advanced technology, careful planning, and rigorous quality control, the manufacturing process of medical CNC components not only meets but often exceeds the demanding requirements of the healthcare sector, contributing to innovations in medical treatments and devices.

Quality Assurance and Regulatory Compliance

Quality assurance is a fundamental aspect of manufacturing precision CNC components in the medical sector. The safety and efficacy of medical devices heavily rely on components that meet stringent regulatory standards. One of the prominent frameworks guiding this is ISO 13485, which specifies requirements for a quality management system (QMS) that organizations must fulfill to demonstrate their ability to provide medical devices and related services that consistently meet customer and regulatory requirements. Adhering to such standards not only ensures that the components produced are of the highest quality but also boosts the organization’s credibility in the eyes of regulatory bodies and stakeholders.

The medical industry faces rigorous scrutiny, necessitating compliance with various regulations, such as the FDA’s Quality System Regulation (QSR) and the European Medical Device Regulation (MDR). These regulations are designed to ensure that medical devices are produced in a controlled environment, minimizing risks associated with product defects. Consequently, manufacturers of CNC components must implement effective quality control measures throughout the production process. This includes regular audits, validation of manufacturing processes, and thorough testing to ensure that all components fulfill both design specifications and regulatory requirements.

Furthermore, the integration of advanced technologies such as automated inspection systems plays an essential role in maintaining quality assurance. These systems enable real-time monitoring and testing of components, allowing for immediate identification and rectification of any deviations from acceptable standards. Utilizing such technologies not only enhances efficiency but also strengthens the trust between manufacturers and regulatory agencies concerning compliance. In this highly regulated landscape, it is crucial for manufacturers to prioritize quality assurance as a means to safeguard public health and contribute to the evolution of innovative medical solutions.

Innovations in CNC Technology for Medical Applications

The medical industry has experienced significant advancements in CNC machining technology, optimizing the performance and reliability of precision components. One notable innovation is the enhancement of software algorithms that increase the accuracy and efficiency of CNC machines. These advancements facilitate real-time monitoring and adjustments, ensuring that components are produced with unmatched precision. Such technological improvements grant manufacturers the ability to produce intricate designs that meet the stringent demands of medical applications.

Moreover, the introduction of cutting-edge materials has further transformed CNC machining processes in the medical field. Biocompatible materials, such as specialized polymers and alloys, are now widely used, ensuring that surgical instruments and implants not only perform effectively but also integrate seamlessly with human tissue. Through CNC machining, manufacturers can achieve complex geometries that were previously unfeasible using traditional manufacturing techniques. This capability allows for customized solutions tailored to individual patient needs, leading to enhanced medical outcomes.

Another area of innovation is the integration of additive manufacturing techniques with CNC technology. This hybrid approach allows for the rapid prototyping of components while maintaining the precision and quality associated with CNC machining. By combining subtractive and additive methods, the fabrication process becomes more versatile, enabling the production of lightweight and intricate structures suitable for a variety of medical applications, from orthopedic implants to dental devices.

Additionally, the adaptability of CNC machinery has been boosted through the incorporation of intelligent systems and automation. These advancements allow for greater flexibility in production runs, making it feasible to quickly switch between different manufacturing tasks without significant downtime. As medical needs evolve, such adaptability is critical, empowering manufacturers to respond efficiently to emerging requirements.

In summary, the integration of innovations in software, materials, and hybrid manufacturing techniques is revolutionizing precision CNC components in the medical industry. These advancements ensure that the demands for accuracy and efficiency in medical applications are met, paving the way for enhanced care and improved patient outcomes.

Case Studies of CNC Components in Medical Devices

The application of precision CNC components in the medical industry has transformed various medical devices, leading to enhanced performance and improved patient outcomes. A notable case is the development of orthopedic implants, where precision machined components have become integral. An orthopedic company utilized CNC technology to manufacture custom-fit joint replacements. The result was a significant reduction in surgery time and a faster recovery for patients, demonstrating how CNC components can be tailored to meet unique patient anatomies.

Another exemplary instance is found in the realm of surgical instruments. A leading manufacturer implemented CNC processes to produce highly intricate surgical tools, such as scissors and forceps. The precision achieved through CNC machining allowed for better ergonomic designs and enhanced operational efficacy. This not only improved the usability of the instruments but also ensured safety during surgeries, thereby contributing positively to patient care and outcomes.

In the field of diagnostic equipment, CNC components significantly improved ultrasound machines. A manufacturer employed CNC technology to create refined internal components, which enhanced the accuracy of imaging. By optimizing these crucial parts, the manufacturers achieved higher resolution images and reduced the time required for diagnosis. This underscores how precision CNC components are not just about output efficiency but are pivotal in improving the overall quality of healthcare.

Furthermore, the use of CNC milled components in infusion pumps exemplifies another successful application. These devices require highly calibrated parts to administer medication accurately and safely. The incorporation of precision CNC components allowed for tight tolerances and reliable performance, ensuring that patients receive exact dosages without error. Across these examples, it is evident that precision CNC components play a vital role in driving innovation within the medical field, ultimately leading to enhanced patient care and successful medical advancements.

Challenges in CNC Manufacturing for the Medical Sector

The manufacturing of CNC components for the medical industry presents a unique set of challenges that require careful consideration and adept handling. One significant issue pertains to the limitations of equipment and technology. In this sector, precision is paramount, as even the smallest deviation can lead to serious implications for patient safety. Many manufacturers may struggle with older machinery that lacks the necessary precision and capabilities, hindering their ability to meet stringent medical standards.

Maintaining precision is further complicated by the varying environmental conditions under which CNC machining takes place. Factors such as temperature fluctuations and humidity can influence the machining process, impacting the integrity of the components produced. Manufacturers need to implement rigorous environmental controls and invest in advanced tooling and fixtures that can accommodate these variables, ensuring consistent quality and reliability in their output.

Additionally, navigating the complex regulatory landscapes associated with the medical industry adds another layer of challenge. Strict guidelines from regulatory bodies, such as the FDA, dictate the manufacturing processes and the documentation required to ensure compliance. This can be particularly daunting for manufacturers unfamiliar with the medical sector’s regulations. To address these challenges, manufacturers must invest in training their staff to understand compliance requirements and maintain thorough documentation throughout the manufacturing process.

Potential solutions include adopting advanced CNC technologies that offer enhanced precision and flexibility, as well as conducting regular equipment maintenance to ensure optimal performance. Furthermore, collaborating with regulatory experts can streamline processes and facilitate a clearer understanding of the requirements. By focusing on these best practices, manufacturers can mitigate challenges in CNC manufacturing, leading to the production of high-quality components that meet the demands of the medical industry.

The Future of Precision CNC Components in the Medical Industry

The landscape of the medical industry is evolving at an unprecedented pace, driven largely by advancements in technology and a growing demand for personalized healthcare solutions. As such, the future of precision CNC components is set to play a pivotal role in this transformation. Medical professionals and manufacturers are increasingly recognizing the importance of tailored medical devices that cater to individual patient needs. This shift towards personalized medicine necessitates the utilization of CNC components that can be produced with high precision, thus ensuring optimal performance and safety.

Furthermore, the advent of 3D printing technology is facilitating a revolution in how medical components are designed and manufactured. Combining CNC machining with additive manufacturing opens a multitude of possibilities, allowing for the production of complex geometries that were once deemed impossible with traditional techniques. This synergy not only enhances the customization potential for medical devices but also streamlines the production process, ultimately reducing lead times and costs. As 3D printing becomes more integrated into the manufacturing ecosystem, precision CNC components will also evolve to complement these advancements, ensuring that rigorously high standards are met.

Another trend worth noting is the increasing focus on biocompatibility for precision CNC components. As medical devices are often in direct contact with biological tissues, the demand for materials that adhere to regulatory standards is critical. The development of innovative, biocompatible materials will drive CNC machining techniques to adapt and optimize processes, thereby ensuring that the components produced contribute effectively to patient health and recovery.

In conclusion, the future of precision CNC components in the medical industry is promising. With the trends of personalized medicine and 3D printing leading the charge, the ability of CNC technology to adapt will be crucial in addressing the evolving challenges of healthcare, all while maintaining the highest levels of precision and quality assurance.