Introduction to Optical Parts Processing

Optical parts processing is a specialized field that involves the design, fabrication, and refinement of components that manipulate light for various applications. This discipline plays a crucial role in industries such as manufacturing, telecommunications, and healthcare, where the precision and quality of optical components can significantly impact functionality and performance. The importance of optical parts processing is underscored by its widespread use in developing advanced technologies like laser systems, fiber optics, and medical imaging devices.

In the manufacturing sector, optical components are integral in producing machinery that necessitates precision and high-quality optical elements, such as lenses, mirrors, and beam splitters. These components are essential for ensuring accuracy and efficiency in industrial processes. In telecommunications, processed optical components are fundamental to the transmission of data over fiber optic networks, facilitating high-speed internet and communication services. Furthermore, in the healthcare industry, optical parts are pivotal for imaging and surgical instruments, impacting patient diagnosis and treatment.

The applications of optical parts extend far beyond these sectors. For instance, enhancements in consumer electronics, including cameras and smartphones, rely heavily on advanced optical processing techniques to improve image quality and functionality. In addition, scientific research employs these refined optical components for various experiments and measurements, illustrating their versatility across domains.

Throughout this blog post, we will explore the intricate technologies and techniques utilized in optical parts processing. We will delve into topics such as precision glass molding, optical coating processes, and computer numerical control (CNC) machining. By examining these elements, we aim to provide a comprehensive understanding of how optical parts processing contributes to innovation and efficiency across multiple industries.

Types of Optical Components

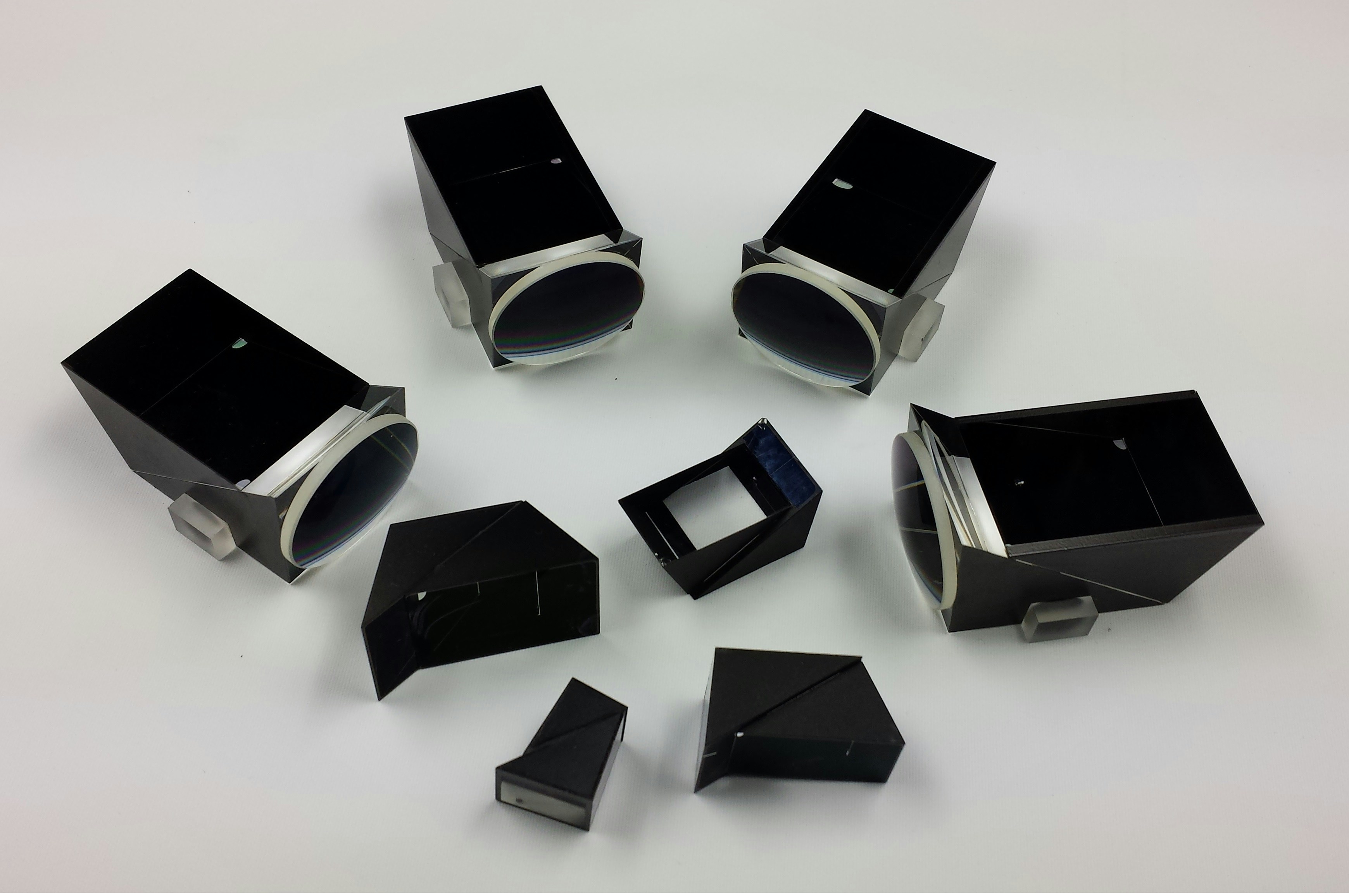

Optical components are essential elements in the field of optics, serving a wide range of functions that are crucial for various applications, from simple optical devices to complex systems in scientific research and telecommunications. The primary types of optical components include lenses, mirrors, prisms, and fiber optics, each playing a unique role in guiding, focusing, or transmitting light.

Lenses are transparent optical elements that manipulate light to converge or diverge rays. They are categorized into two main types: convex lenses, which focus light to a point, and concave lenses, which spread light out. These components are made from materials such as glass or plastic and are pivotal in applications like photography, eyeglasses, and optical instruments.

Mirrors, on the other hand, reflect light to create images. They can be flat or curved, with curved mirrors (concave and convex) typically used in applications requiring image formation or magnification. Materials commonly used for mirrors include polished metal and glass coated with reflective substances. Mirrors are critical in instruments like telescopes, lasers, and in various automotive and architectural applications.

Prisms are transparent optical components that refract light, changing its direction and wavelength. They are utilized for dispersion, beam splitting, or altering the polarization of light. Made from materials such as glass or acrylic, prisms are essential in applications ranging from spectroscopy to optical communication systems.

Lastly, fiber optics are specialized components that transmit light through flexible transparent fibers. They work on the principle of total internal reflection, enabling data transmission over long distances with minimal loss. Fiber optics are indispensable in telecommunications, medical devices, and networking due to their high efficiency and speed.

Materials Used in Optical Processing

The production of optical components relies heavily on a diverse array of materials, each offering unique properties essential for optimizing performance. Among the most commonly utilized materials are glass and plastics, along with various specialized coatings that further enhance the properties of these substrates.

Glass has long been a staple in optical parts processing due to its excellent transparency and ability to withstand high temperatures. Optical glass, in particular, features a high degree of purity, allowing for superior light transmission without significant distortion. Additionally, its rigidity provides structural integrity to optical components like lenses and prisms. However, glass is also heavier and more brittle, which can pose challenges during handling and installation.

On the other hand, plastic optics have garnered interest for their lightweight and impact-resistant characteristics. Materials such as polycarbonate and acrylic allow for a wide range of optical designs and lower production costs compared to traditional glass. Although plastics generally offer good optical clarity, they can be more susceptible to scratching and have a lower thermal stability, potentially limiting their application in high-stress environments.

Specialized coatings serve to amplify the properties of both glass and plastic materials. Anti-reflective coatings are critical in reducing light loss and enhancing transmission efficiency. Similarly, reflective coatings are vital for applications that necessitate efficient light management. A careful selection of the right coatings can mitigate the limitations of base materials, improving overall optical performance.

In the realm of optical parts processing, the choice of material significantly influences manufacturing processes and final product quality. Understanding the advantages and disadvantages of glass, plastic, and coatings allows for informed decisions that lead to enhanced optical components suitable for varying applications.

Processing Techniques for Optical Components

The production of optical components involves a variety of processing techniques that are crucial for ensuring the desired quality and performance of the final product. Among the most commonly used methods are grinding, polishing, coating, and shaping. Each technique has its own set of applications, advantages, and technological advancements that contribute to the evolution of optical parts manufacturing.

Grinding is typically the preliminary step in the processing of optical components. This technique involves the use of abrasive wheels to remove material and achieve the basic shape of the optical part. Innovations in diamond grinding technology have significantly improved the efficiency and precision of this method, allowing for tighter tolerances and finer surface finishes. Utilizing computer numerical control (CNC) systems, manufacturers can now produce intricate geometries and complex optical surfaces more reliably than ever.

Following grinding, polishing is employed to refine the surface quality further. This technique aims to achieve a smoother surface finish by employing finer abrasives and additives. Recent advancements in polishing methods, including the introduction of magnetorheological polishing and chemical-mechanical polishing, have enabled manufacturers to achieve optical-grade surfaces with minimal subsurface damage. These innovations have proven essential for applications demanding high optical performance, such as in lenses and mirrors used in advanced imaging systems.

Another vital aspect of optical components processing is the application of coatings. Optical coatings are essential for enhancing the performance of optical parts, improving properties like reflection, transmission, and durability. Modern techniques such as atomic layer deposition and sputter coating have expanded the capabilities of coating processes, allowing for the creation of multilayer coatings with precise control over thickness and material composition.

Finally, shaping techniques, including molding and machining, are employed to achieve the final dimensions and features of optical components. Recent technological advancements have led to more efficient and cost-effective molding techniques, significantly benefiting mass production scenarios. Overall, the interplay of these processing techniques highlights the complexity and intricacy of creating high-quality optical components, reflecting both the art and science involved in their production.

Precision Measurement and Quality Control

In the realm of optical parts processing, quality assurance is paramount. Achieving high standards requires rigorous precision measurement techniques and quality control methods. Various tools and methodologies play a vital role in ensuring that optical components adhere to the required specifications and perform optimally in their intended applications.

One of the key aspects of quality control in this domain is surface roughness measurement. The surface finish of optical components directly affects their performance, particularly in applications involving light transmission and reflection. Sophisticated instruments, such as optical profilers and surface roughness testers, are employed to provide detailed analyses of surface textures. These measurements allow manufacturers to verify that components meet the critical surface profiles necessary for high-performance optics.

Interferometry stands as another prominent technique in the precision measurement of optical parts. This method utilizes the principle of interference of light waves to evaluate both surface contours and thickness variations of optical materials. By comparing the interference patterns produced, engineers can detect minute deviations from the desired specifications, enabling high-accuracy evaluations. Interferometry is crucial, especially in the production of lenses and mirrors, where precision ensures the quality of imaging and optical performance.

Beyond these technical tools, visual inspection methods remain indispensable in the quality control process. Human expertise is utilized to identify potential defects such as scratches, bubbles, or inconsistencies on optical components. Although automated methods are increasingly employed for surface inspection, the human eye brings an essential layer of qualitative assessment that complements machine-generated data, ensuring that components not only meet quantitative standards but also exhibit the necessary craftsmanship.

In conclusion, precision measurement and quality control are integral to the optical parts processing industry. By incorporating advanced measurement tools and inspection techniques, manufacturers can uphold the quality and performance standards demanded by both industry and end-users.

Challenges in Optical Parts Processing

Processing optical parts entails a myriad of challenges that can significantly impact the quality and performance of the final products. One of the primary obstacles is achieving uniformity in production. Variability in raw materials, environmental conditions, and process parameters can lead to inconsistencies in dimensions and optical properties. This variability can result in a range of issues, including varying levels of transmission, aberrations, and an inability to meet strict specifications required for high-quality optical components.

Another challenge is the management of defects and imperfections during the optical parts processing. Common defects, such as scratches, pits, and subsurface damage, can arise from various stages of manufacturing, including grinding, polishing, and coating. The presence of these imperfections not only affects the aesthetic appeal but also compromises the optical performance of the components, leading to increased rejection rates and production costs. To combat this, technology advancements, such as automated inspection systems and real-time monitoring tools, are being employed to detect defects early in the process. These solutions facilitate immediate corrective actions, thus minimizing waste and rework.

Additionally, the complexity of designing custom optical components poses another set of difficulties. As industries increasingly rely on bespoke optical solutions, the demand for precision and accuracy escalates. Meeting these demands necessitates advanced computational methods and simulation software to predict optical behavior before fabrication. Moreover, the integration of materials science knowledge is essential in developing new optical materials that can withstand the rigors of processing without sacrificing performance.

In addressing these challenges, continuous investment in research and development is critical. By embracing new technologies and methodologies, manufacturers can enhance the efficiency and reliability of optical parts processing, ultimately leading to improved products that meet stringent quality standards.

Innovations in Optical Processing Technologies

Recent advancements in optical processing technologies have transformed the landscape of manufacturing and designing optical components. Among these innovations, laser processing has emerged as a pivotal technique due to its precision, speed, and versatility. Utilizing high-intensity lasers, manufacturers can achieve intricate patterns in materials, enhancing their optical properties. This method not only improves the quality of optical components but also reduces the production time significantly, leading to better efficiency and cost-effectiveness in manufacturing.

In addition to laser processing, digital fabrication methods have gained prominence in the realm of optical parts processing. Techniques such as 3D printing and microfabrication allow for intricate designs that were previously unattainable through traditional manufacturing methods. These innovations facilitate the creation of highly customized optical components tailored to specific applications. Furthermore, the integration of digital technologies streamlines the design process, enabling rapid prototyping and iterative improvements, which ultimately accelerate time-to-market for new optical devices.

Nanothermology is another significant area contributing to advancements in optical processing technologies. Through the manipulation of materials at the nanoscale, researchers can enhance the functionality of optical components, imparting desirable properties such as improved light absorption and better transmission efficiency. The applications of nanotechnology continue to expand, allowing for the design of novel materials that exhibit unique optical characteristics, paving the way for innovative products in industries ranging from telecommunications to medical devices.

Overall, the ongoing innovations in optical processing technologies are redefining the capabilities and performance of optical components. As laser processing, digital fabrication, and nanotechnology evolve, they pave the way for more efficient, cost-effective, and sophisticated optical solutions that cater to the ever-growing demands of modern applications.

Future Trends in Optical Parts Processing

As the optical parts processing industry continues to evolve, several significant trends are anticipated to shape its future. One of the foremost trends is the advancement in automation technologies. Manufacturers are increasingly adopting automated systems to streamline production processes, reduce human error, and enhance efficiency. Automation not only optimizes production lines but also enables greater precision in the fabrication of intricate optical components, essential for applications ranging from telecommunications to healthcare.

Another pivotal trend is the increasing integration of artificial intelligence (AI) in the processing of optical parts. AI technologies facilitate improved data analysis and decision-making, helping manufacturers to predict equipment failures, optimize maintenance schedules, and enhance production planning. Moreover, machine learning algorithms can analyze quality metrics, leading to real-time adjustments during the manufacturing process. This integration is expected to significantly increase production quality and reduce waste, presenting a vital advancement for the industry.

Furthermore, sustainability practices are becoming increasingly important in optical parts manufacturing. As environmental awareness grows, manufacturers are seeking to implement greener and more sustainable processes. This involves adopting eco-friendly materials, reducing energy consumption, and minimizing waste during optical parts processing. The shift towards sustainability not only addresses regulatory pressures but also meets the evolving expectations of consumers and stakeholders who favor environmentally responsible production methods.

Additionally, the rise of precision optics and customized solutions is likely to influence market dynamics. As industries demand more specialized optical components, manufacturers may increasingly focus on developing tailored solutions to meet specific requirements. Such a trend underscores the need for agility and innovation in optical parts processing, fostering a landscape ripe for new technologies and methodologies.

Overall, these emerging trends provide a glimpse into the future of optical parts processing, highlighting the possibilities for technological enhancements and sustainable practices that will define the industry in the coming years.

Conclusion

In reviewing the intricacies of optical parts processing, several pivotal points emerge that underscore its importance across varied industries. Optical parts, encompassing components such as lenses, mirrors, and prisms, serve as fundamental elements in the functionality of numerous devices ranging from consumer electronics to advanced scientific instruments. The methods employed in the processing of these optical components involve precise machining, surface treatment, and coating technologies, each contributing to the enhancement of performance and clarity. This amalgamation of techniques showcases the balance of art and science in creating efficient optical systems.

Moreover, the varying applications of optical parts processing across sectors like telecommunications, aerospace, and healthcare highlight the necessity for continuous innovation in this domain. As technologies evolve, so do the demands for higher precision, durability, and functionality in optical components. These advancements not only improve existing systems but also foster the development of new applications, thus sustaining the growth and relevance of optical processing techniques. The intersection of research, engineering, and technological development in this field is paramount for addressing the challenges posed by modern devices.

Encouraging an inquisitive mindset among professionals and enthusiasts alike is essential for maintaining a competitive edge in optical parts processing. Keeping abreast of emerging trends and techniques will empower individuals and organizations to adapt swiftly and effectively to the shifting technological landscape. Continuous learning and exploration within this discipline are not merely beneficial but essential for those seeking to master the art and science of optical components. As we look to the future, the implications of optical parts processing are vast, promising further advancements that will shape numerous aspects of our daily lives.