Introduction to CNC Machining in the Pharmaceutical Industry

Computer Numerical Control (CNC) machining has revolutionized various industries, particularly the pharmaceutical sector, where precision and compliance are paramount. This advanced manufacturing process utilizes computer software to control machinery and tools, allowing for unparalleled accuracy in producing complex parts. In the pharmaceuticals industry, where consistency and quality are crucial, CNC machining plays an integral role in ensuring that components meet rigorous standards.

The relevance of CNC machinery in pharmaceutical manufacturing lies in its ability to streamline production processes. With the capacity to create intricate designs with minimal human intervention, CNC machining reduces the potential for errors that could compromise product integrity. By automating the machining process, manufacturers can increase output efficiency and maintain a consistent quality level, which is essential for meeting the high demands of the marketplace.

Moreover, CNC machining aligns with the stringent regulatory requirements governing the pharmaceutical industry. Compliance with these regulations is critical, as failure to adhere to established standards may result in severe repercussions. CNC technology enables manufacturers to deliver products that conform to specifications by precisely executing designs that reflect the exact dimensions and tolerances specified.

This precise engineering capability not only enhances product quality but also minimizes waste, thus increasing the overall sustainability of pharmaceutical manufacturing. Additionally, the ability to produce prototypes quickly and with high fidelity allows for faster product development cycles, which is vital in an industry characterized by rapid innovation and frequently changing regulations.

In essence, CNC machining serves as a vital component in the pharmaceutical sector, providing a means of achieving high standards of precision while simultaneously meeting the demanding regulatory challenges that define the industry.

Benefits of CNC Machining for Pharmaceutical Components

CNC (Computer Numerical Control) machining has revolutionized the production of pharmaceutical components, offering various advantages that enhance both the efficiency and reliability of manufacturing processes. One of the most significant benefits is enhanced accuracy. Since CNC machines operate through precise programming, they can achieve tolerances down to a few microns, which is critical in the pharmaceutical industry where the precision of components can directly impact the effectiveness of medical products.

Alongside improved accuracy, CNC machining greatly reduces lead times. Traditional machining can be time-consuming, but CNC machining automates the manufacturing process, enabling rapid prototyping and quicker production runs. This efficiency allows pharmaceutical companies to respond timely to market demands, ensuring they can deliver products to patients without unnecessary delays.

Scalability is another crucial advantage offered by CNC machining. Once a design is programmed into the system, it can be replicated with minimal adjustments, seamlessly transitioning from small-scale production to mass production. This capability is particularly beneficial in the pharmaceutical sector, where companies must frequently scale up production to meet changing demands or launch new products.

Moreover, consistency in manufacturing is paramount for pharmaceutical components to ensure safety and effectiveness. CNC machining provides repeatability throughout the manufacturing process, making it easier to maintain product specifications across all units produced. This consistency is vital, especially in producing parts for medical devices or drug delivery systems that require uniformity to function correctly.

In summary, the benefits of CNC machining—enhanced accuracy, reduced lead times, scalability for mass production, and improved consistency—make it an invaluable method in the manufacturing of pharmaceutical components. By leveraging these advantages, companies can ensure they meet regulatory standards while remaining competitive in a highly regulated industry.

Types of Pharmaceutical Parts Manufactured via CNC Machining

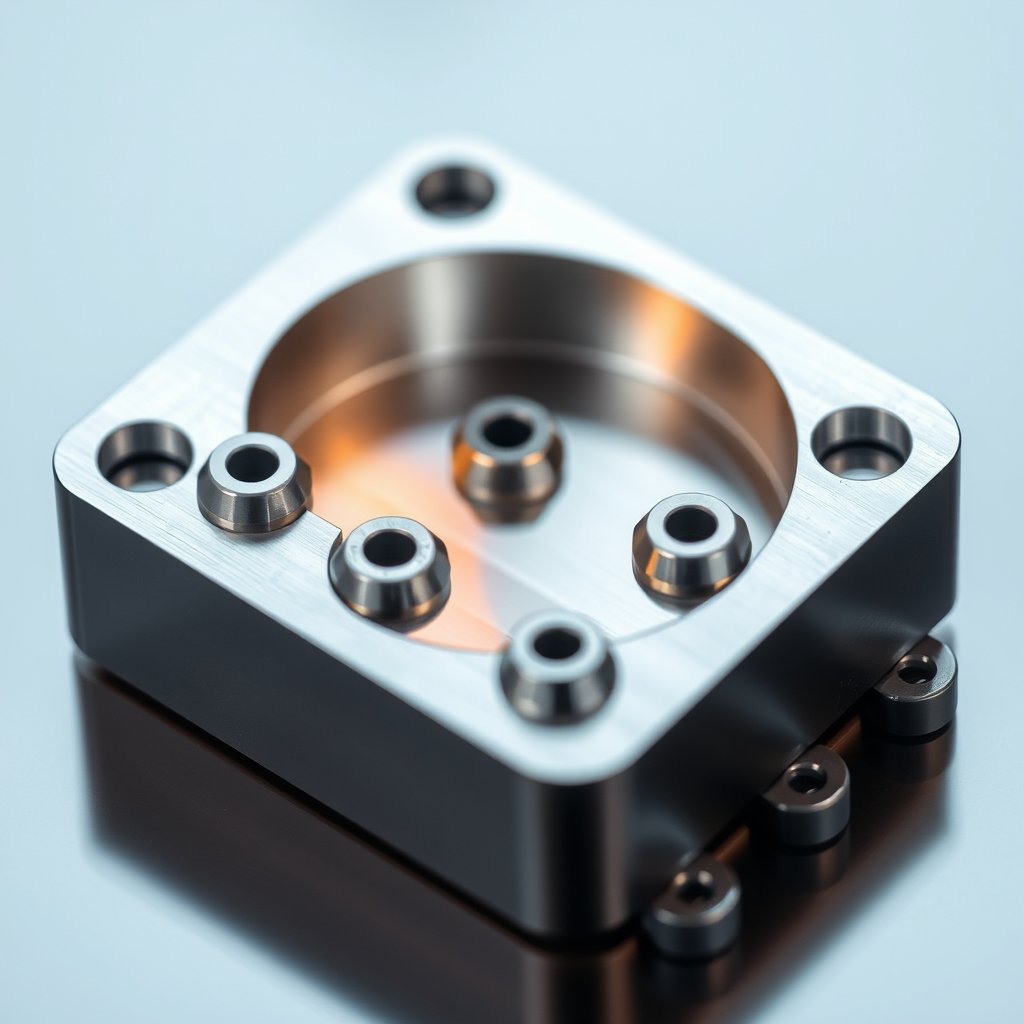

CNC machining plays a pivotal role in the production of various pharmaceutical parts, ensuring precision and adherence to stringent industry standards. This technology is employed for manufacturing an array of components, including drug delivery systems, surgical instruments, lab equipment, and packaging machinery parts. Each category has specific design specifications and functional requirements tailored to meet the needs of the pharmaceutical sector.

Drug delivery systems, such as syringes, inhalers, and transdermal patches, are often crafted using CNC machining. The precision of this process allows for the creation of intricate features that ensure accurate dosages, maximized efficacy, and improved patient compliance. The choice of materials, including medical-grade plastics and metals, further enhances the system’s performance while adhering to regulatory guidelines.

Surgical instruments are another crucial category where CNC machining is frequently utilized. Instruments like scalpels, forceps, and retractors require high precision and durability to maintain sterile conditions and flawless execution in surgical procedures. The manufacturing process often involves the use of stainless steel or titanium due to their strength and biocompatibility, ensuring that the instruments withstand rigorous usage while minimizing risks of infection or mechanical failure.

Lab equipment components, including test tubes, pipettes, and centrifuge parts, are essential for pharmaceutical research and development. CNC machining enables the production of these components with high tolerances and repeatability, facilitating reliable laboratory results. The materials used often include glass, plastic, and corrosion-resistant metals, selected based on the specific application requirements.

Packaging machinery parts, such as conveyor belts and sealing mechanisms, are vital for the safe and efficient packaging of pharmaceutical products. CNC machining can create custom components that enhance the performance and efficiency of packaging lines, ensuring protection against contamination and maintaining product integrity. The reliable fabrication of these parts contributes significantly to the overall productivity of the pharmaceutical manufacturing process.

Materials Used in CNC Machining for the Pharmaceutical Industry

CNC machining serves as a critical method in the manufacturing of pharmaceutical parts, where the selection of appropriate materials is paramount. The pharmaceutical industry demands a high level of precision and compliance with stringent regulations, and therefore, the materials chosen for CNC machining must meet specific criteria. Among the most commonly utilized materials are stainless steel, various types of plastics, and biocompatible materials.

Stainless steel is frequently employed due to its excellent durability and resistance to corrosion. It can withstand high-temperature sterilization processes, making it an ideal choice for manufacturing devices such as syringes, surgical instruments, and various equipment used in drug formulation. The mechanical properties of stainless steel, combined with its ability to be easily cleaned and sterilized, ensure compliance with industry standards.

Plastics also play a vital role in CNC machining for pharmaceuticals. Materials such as polycarbonate, polyvinyl chloride (PVC), and polypropylene are often used due to their lightweight properties, chemical resistance, and versatility. These plastics can be engineered to meet specific needs, including transparency, flexibility, and resistance to harsh chemicals. They are particularly useful in disposable applications and low-cost components.

Biocompatible materials are another category that holds significance in this industry. These materials are specifically designed to be safe for use in medical applications, minimizing any adverse reaction when in contact with biological systems. Polymers like polylactic acid (PLA) and other specialized compounds ensure that the end products not only meet performance standards but also adhere to safety requirements mandated by regulatory bodies.

In conclusion, the choice of materials in CNC machining for pharmaceutical applications is dictated by the requirements of durability, chemical resistance, and regulatory compliance. This careful selection process ensures the production of reliable and efficient pharmaceutical components, ultimately contributing to the advancement of healthcare solutions.

The Role of Precision and Tolerances in Pharmaceutical Machining

In the highly regulated pharmaceutical industry, the need for precision in manufacturing processes cannot be overstated. CNC machining plays a pivotal role in achieving the stringent tolerances required for pharmaceutical parts. This technology allows manufacturers to produce components that meet exact specifications, crucial for ensuring efficacy and safety in pharmaceutical applications.

Pharmaceutical parts often require tight tolerances, defined as the allowable limits of variation in dimensions and other characteristics. These tolerances guarantee that components function correctly within complex systems, directly impacting drug formulation and delivery. For instance, the precise manufacture of syringe components ensures accurate dosage, while the meticulous creation of implantable devices can dramatically affect patient outcomes. As such, even minute deviations can lead to significant issues, including product recalls or regulatory violations.

Advanced CNC machining technologies are equipped with high-resolution tools and software capable of monitoring and adjusting processes in real-time. These innovations not only enhance the accuracy of machined parts but also optimize efficiency, reducing the likelihood of errors during production. By utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, manufacturers can produce intricate geometries and complex shapes that are often required in pharmaceutical applications.

The integration of quality control measures further supports the quest for precision. Techniques such as laser scanning and coordinate measuring machines (CMM) allow for thorough inspection of finished parts, ensuring they conform to the defined tolerances. This meticulous quality assurance process is integral for maintaining compliance with industry regulations and safeguarding patient health.

Ultimately, achieving tight tolerances through CNC machining is not merely about maintaining production standards; it is about ensuring product performance and safety in the pharmaceutical sector. The fusion of advanced technology and rigorous manufacturing practices underscores the importance of precision in creating effective and safe pharmaceutical parts.

Regulatory Considerations in CNC Machining for Pharmaceuticals

The pharmaceutical industry operates under stringent regulatory frameworks to ensure product safety, efficacy, and quality. As companies engage in CNC machining for pharmaceutical parts, it is paramount that they adhere to these regulations, primarily set forth by agencies such as the Food and Drug Administration (FDA). The FDA provides guidelines that govern all aspects of pharmaceutical manufacturing, insisting on a rigorous approach to any process involved in the production of medicinal products.

One critical aspect of these regulations is the Good Manufacturing Practices (GMP), which stipulate that manufacturers must operate in a controlled environment to minimize risks related to contamination, mix-ups, and errors. CNC machining processes must be meticulously designed and executed to meet GMP standards, ensuring that the equipment used is capable of producing parts that are not only precisely manufactured but also compliant with the required specifications. The precision offered by CNC machining plays a vital role in achieving the level of detail required for pharmaceutical components like syringes or vials, which are essential for proper drug administration.

Moreover, proper documentation is a vital regulatory consideration in this sector. Each step of the CNC machining process must be documented to provide transparency and traceability. This ensures that the operations can be verified and validated, demonstrating compliance with regulatory standards. Manufacturers must also ensure that their quality management systems are robust enough to handle audits and inspections, which are common in this highly regulated landscape.

In conclusion, understanding and integrating regulatory considerations into CNC machining processes is not just about compliance but also about maintaining the highest standards of product quality and safety in the pharmaceutical industry. The interplay of precise engineering and strict regulations underscores the significance of CNC machining as an essential component in the manufacture of pharmaceutical parts.

Quality Control and Inspection Processes

In the realm of CNC machining for pharmaceutical parts, the importance of stringent quality control and thorough inspection processes cannot be overstated. Given the highly regulated nature of the pharmaceutical industry, ensuring that each part meets precise specifications is critical to the overall safety and efficacy of healthcare products. The implementation of robust quality control measures facilitates compliance with industry standards and governmental regulations.

Inspection techniques are pivotal to achieving the desired level of accuracy and precision in CNC machined components. Common methods include visual inspections, dimensional checks using calibrated measuring tools, and advanced technologies such as coordinate measuring machines (CMM). Visual inspections serve as the first line of defense, enabling operators to detect surface defects and other anomalies. Dimensional checks ensure that every part adheres to predetermined specifications, while CMM provides a comprehensive assessment of complex geometries through 3D scanning.

Testing standards further reinforce quality assurance in the manufacturing of pharmaceutical parts. Adhering to international standards such as ISO 13485 ensures that the manufacturing process aligns with best practices in quality management systems specifically tailored for medical devices. Routine audits, alongside regular proficiency testing, confirm that manufacturers consistently deliver products that are compliant with these stringent criteria.

Moreover, automation plays a pivotal role in elevating the quality assurance processes within CNC machining. Automated inspection systems can perform real-time monitoring and analysis throughout the machining process, reducing human error and enhancing accuracy. By integrating technologies such as artificial intelligence and machine learning, manufacturers can identify potential defects earlier, allowing for immediate corrective actions. This proactive approach contributes significantly to maintaining high-quality standards consistently across all pharmaceutical parts produced.

Future Trends in CNC Machining for the Pharmaceutical Industry

The pharmaceutical industry is undergoing substantial transformation driven by advancements in technology, and CNC machining is at the forefront of these changes. As the demand for precision and efficiency increases, several future trends are poised to reshape how pharmaceutical parts are manufactured. One of the leading trends is the integration of Artificial Intelligence (AI) and machine learning into CNC machining processes. These technologies facilitate predictive maintenance, optimize machining parameters, and enhance quality control. By analyzing data from various machining operations, AI can identify patterns and suggest improvements, thereby augmenting overall productivity. This data-driven approach not only minimizes the likelihood of errors but also enables manufacturers to achieve consistent and high-quality results, which are critical in a regulated industry.

Another pivotal trend in CNC machining is the adoption of Industry 4.0 practices. This encompasses a shift towards smart manufacturing, where interconnected machines, systems, and processes communicate and collaborate seamlessly. In the pharmaceutical sector, Industry 4.0 enables real-time monitoring and adjustments during machining operations, thereby ensuring compliance with stringent regulatory requirements. Additionally, the use of IoT (Internet of Things) devices can enhance traceability throughout the production process, allowing for better tracking of materials and processes.

Innovations in materials and processes are also set to play a significant role in the future of CNC machining for pharmaceutical applications. The demand for biocompatible materials is on the rise, as pharmaceutical manufacturers seek to develop parts that meet specific regulatory standards. Advances in additive manufacturing and hybrid machining techniques are expanding the possibilities for creating complex geometries and improving material efficiency. These developments ensure that the industry can meet the evolving needs of drug delivery systems and other critical applications.

In conclusion, the future of CNC machining in the pharmaceutical industry appears bright, characterized by AI integration, Industry 4.0 practices, and innovative materials. As these trends evolve, they will undoubtedly enhance the precision and efficiency of manufacturing processes, aligning with the industry’s commitment to high standards of quality and safety.

Conclusion: The Impact of CNC Machining on Pharmaceutical Efficiency

As we have examined throughout this discussion, CNC machining has emerged as a vital technology in the pharmaceutical industry, driving notable improvements in both efficiency and product quality. The precision engineering capabilities that CNC machining offers play a critical role in ensuring that pharmaceutical parts meet stringent regulatory standards. This technology allows manufacturers to produce components with exceptional accuracy, minimizing the potential for errors that could adversely affect patient safety.

Moreover, the ability to quickly and efficiently produce complex geometries via CNC machining streamlines the manufacturing process. This efficiency not only reduces lead times but also enhances overall productivity. By integrating CNC machining into their operations, pharmaceutical companies can rapidly respond to market demands, adjusting production levels in real-time without compromising quality or compliance with regulatory requirements.

In addition to improving efficiency, CNC machining contributes to consistent product quality. The automation and computer-controlled nature of the processes ensures that every unit produced adheres to the same precise specifications. This level of consistency is essential in the pharmaceutical arena, where product variability can lead to significant health implications and legal repercussions. Furthermore, with advancements in CNC technology, manufacturers are continuously able to refine their processes, resulting in better materials utilization, lower waste generation, and reduced operational costs.

In conclusion, the strategic implementation of CNC machining in the pharmaceutical sector not only facilitates enhanced manufacturing capabilities but also underscores the importance of innovation in meeting industry challenges. By prioritizing precision and efficiency, CNC machining stands as a pivotal element in modern pharmaceutical manufacturing, ultimately fostering a landscape where patient safety and product excellence are paramount.