Introduction to CNC Machining

CNC machining, which stands for Computer Numerical Control machining, represents a significant advancement in manufacturing technology. This process utilizes computer systems to control machine tools, enabling the automated production of components with precision and consistency. In contrast to traditional machining methods, where manual input is necessary to guide the machine tools, CNC machining is fully automated, allowing for higher efficiency and a reduction in human error. This is particularly beneficial in the automotive industry, where the demand for precise and durable parts is paramount.

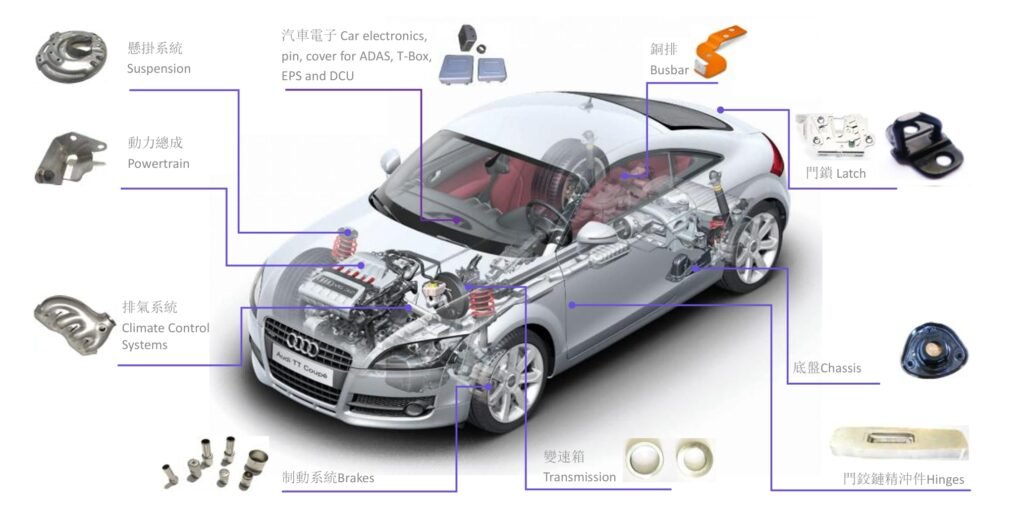

The utilization of CNC machines has transformed how automotive components are manufactured, allowing for intricate designs and complex geometries that would be virtually impossible to achieve through manual methods. Components such as engine blocks, transmission housings, and custom brackets can now be manufactured with high levels of accuracy, which is essential for performance and safety. Furthermore, CNC machining offers significant benefits in terms of repeatability; once a design is programmed into the machine, it can produce identical parts consistently, ensuring uniform quality across all components.

In addition to precision, CNC machining enhances the flexibility of production processes. Manufacturers can quickly switch between different designs and adapt to changing market demands without the need for extensive manual retooling. This adaptability is critical in an industry known for its rapid technological advancements and evolving consumer preferences. The integration of CNC machining into the automotive manufacturing process not only streamlines production but also aids in reducing waste and improving overall efficiency.

As we delve deeper into the various aspects of CNC machining for automotive parts, it is evident that this technology plays a pivotal role in revolutionizing the industry, making it an essential focus for manufacturers seeking to enhance their competitive edge.

Key Benefits of CNC Machining in the Automotive Industry

The utilization of CNC machining in the automotive industry brings forth numerous benefits that significantly enhance manufacturing processes. One of the most notable advantages is improved precision. CNC machines operate with minimal tolerances, producing parts with a level of accuracy that is difficult to achieve through traditional manufacturing methods. This precision is crucial for automotive components where even the slightest deviation may lead to performance issues or safety concerns.

In addition to precision, CNC machining enhances efficiency in automotive production. The ability to automate complex machining processes allows for faster turnaround times, enabling manufacturers to meet tight deadlines and respond swiftly to market demands. This automation not only streamlines production but also reduces the need for extensive manual labor, leading to lower operational costs. Consequently, many automotive companies are increasingly integrating CNC machining to optimize their workflow and improve overall productivity.

Cost-effectiveness is another significant benefit of adopting CNC machining for automotive parts. Although the initial investment in CNC technology may be substantial, the long-term savings often justify the expenditure. The reduction of material waste during the machining process coupled with the capability to produce multiple components in a single setup minimizes production costs. Furthermore, CNC machining allows for the creation of complex geometries that might be challenging or impossible to achieve using traditional manufacturing techniques, resulting in innovative designs that can enhance vehicle performance and aesthetics.

Moreover, CNC machining contributes to better competition within the automotive sector. By enabling faster production times, reduced material waste, and enhanced design flexibility, manufacturers can offer high-quality parts at competitive prices. This adaptability helps automotive companies stay ahead in a rapidly evolving market, fostering continual advancement in technology and manufacturing practices.

Types of CNC Machines Used in Automotive Manufacturing

CNC machining has become integral to the automotive industry, providing precision and efficiency in the production of various automotive parts. Several types of CNC machines are commonly employed to cater to the diverse needs of automotive manufacturing, each with its unique applications, features, and suitability for different components.

One of the most prevalent types is the CNC mill. These machines utilize rotary cutters to remove material from a workpiece, allowing for intricate designs and complex geometries. CNC mills are particularly useful in manufacturing engine components such as cylinder heads and intake manifolds. Their ability to produce high-precision parts ensures that manufacturers can maintain stringent quality standards across the automotive supply chain.

Another vital machine in the automotive sector is the CNC lathe. Unlike mills, lathes are designed to shape materials by rotating the workpiece against a stationary cutting tool. This machine is especially effective in producing cylindrical parts, which are essential in automotive applications. Typical components fabricated using CNC lathes include axle shafts, pistons, and valve stems. The precision offered by CNC lathes helps meet the demanding performance requirements of modern vehicles.

CNC routers are also gaining traction in the automotive industry. These machines excel at cutting and shaping materials such as plastics, composites, and wood. Although primarily used in producing prototypes and interior parts, CNC routers are increasingly being integrated into the manufacturing of custom automotive features. The flexibility of CNC routers allows for unique designs that can enhance the aesthetic appeal of vehicles.

In conclusion, the variety of CNC machines utilized in automotive manufacturing, including mills, lathes, and routers, exemplifies their crucial role in producing high-quality parts. By understanding the specific applications and strengths of each type, automotive manufacturers can optimize their production processes and meet the evolving demands of the industry.

Materials Commonly Used in CNC Machining of Automotive Parts

CNC machining has transformed the manufacturing process, particularly in the automotive sector, allowing for greater precision and efficiency. A variety of materials are utilized in CNC machining, each selected for its unique properties that cater to specific applications in automotive parts production. Among the most common materials are aluminum, steel, titanium, and plastics, each offering distinct advantages.

Aluminum is widely favored due to its lightweight nature and excellent corrosion resistance, contributing to improved fuel efficiency in vehicles. Its thermal and electrical conductivity also makes it suitable for parts such as engine components and transmission housings. Moreover, aluminum is easy to machine, enabling manufacturers to achieve tight tolerances and complex geometries, which are essential in the automotive industry.

Steel, on the other hand, is renowned for its strength and durability. It is often chosen for structural components that require high strength-to-weight ratios, such as chassis and suspension parts. The ability to alloy steel with elements like chromium and nickel enhances its performance, making it versatile for various applications. CNC machining of steel parts allows for increased accuracy, essential for components that must withstand significant stress and strain during operation.

Titanium, while more expensive, provides exceptional strength while remaining lightweight. These properties make it ideal for high-performance vehicles and aerospace applications within the automotive sector. Titanium’s resistance to extreme temperatures and corrosion further solidifies its position as a preferred material for engine components, exhaust systems, and other critical parts.

Plastics are increasingly utilized in CNC machining owing to their lightweight properties and ability to be molded into intricate shapes. They are often found in non-structural components, such as interior fittings and housings, where a balance between performance and appearance is required. The diverse range of plastics available allows manufacturers to select materials that meet specific functional and aesthetic needs.

The CNC Machining Process: Step-by-Step

The CNC (Computer Numerical Control) machining process is a highly precise manufacturing technique widely utilized in the automotive industry for producing intricate parts. This process comprises multiple essential steps, each contributing to the overall quality and accuracy of the final product. From initial design to the finishing touches, each phase is critical in achieving the desired outcomes.

The first step in the CNC machining process is design and programming. Designers utilize CAD (Computer-Aided Design) software to create detailed 3D models of the automotive parts. Once the designs are approved, they are converted into CNC code, a language that the machine can interpret. This step is vital, as accurate programming ensures that the part will be machined according to the specifications, maintaining the high standards required in the automotive sector.

Following programming, the setup phase begins, where the CNC machine is prepared for operation. This includes selecting appropriate tools, installing fixtures, and calibrating the machine to guarantee precision. It’s during this phase that important quality control measures are implemented. Operators inspect tools and verify that the machine is aligned correctly, which minimizes the risk of errors during machining.

The actual machining process follows setup, involving the removal of material from the workpiece to create the desired shape. The CNC machine operates with high-speed rotary tools, which precisely cut and shape the material according to the programmed instructions. Throughout this process, continuous monitoring ensures adherence to specifications, making adjustments if necessary to uphold quality standards.

Finally, the finishing phase involves polishing and inspecting the produced automotive parts. Additional processes, such as heat treating or surface finishing, may also be employed to enhance durability and aesthetics. Each of these steps illustrates the crucial role of precision within CNC machining, safeguarding the integrity of automotive components while embodying the advancements in manufacturing technology.

Challenges and Limitations of CNC Machining for Automotive Parts

CNC machining has significantly transformed the landscape of automotive manufacturing, offering precise production capabilities and efficiency. However, this advanced technology does not come without its challenges. One of the most pressing hurdles is the issue of machine downtime, which can occur due to various reasons, including mechanical failures or the need for routine maintenance. Such interruptions can result in reduced productivity and increased costs, ultimately affecting the overall competitiveness of manufacturers in the automotive sector.

Another challenge lies in the complexities of programming CNC machines. While these systems allow for high levels of precision and the ability to create intricate designs, the programming process itself can be daunting. Many manufacturers require specialized software and knowledgeable personnel to develop effective CNC machining programs tailored to their specific automotive parts. The learning curve associated with these technologies means that companies may face delays and inefficiencies during the initial implementation phase.

In addition to machine downtime and programming challenges, initial setup costs for CNC machining can be prohibitively high. Purchasing the machines, tools, and requisite software often demands significant capital investment, which can be a substantial barrier for smaller automotive manufacturers. Furthermore, maintaining these systems requires continuous investment in the form of ongoing training for skilled operators. The demand for highly trained personnel can lead to talent shortages, complicating the operational dynamics of businesses that rely on CNC machining.

Despite these challenges, advancements in technology and training programs are emerging to mitigate these issues. For instance, manufacturers are investing in predictive maintenance solutions to reduce machine downtime and enhance productivity. Additionally, user-friendly software interfaces and comprehensive training packages are being developed to ease the programming complexities associated with CNC machining. These innovations hold promise for overcoming the limitations currently faced by the automotive sector.

Future Trends in CNC Machining for Automotive Applications

The automotive industry is on the verge of a significant transformation, driven largely by advancements in CNC (Computer Numerical Control) machining. A pivotal trend is the integration of automation, which enhances production efficiency and reduces labor costs. With the advent of smart manufacturing technologies, CNC machines are becoming more sophisticated, employing robotics and artificial intelligence (AI) to streamline the machining process. This amalgamation facilitates faster production cycles and increased precision, vital elements in meeting the high demands of the automotive sector.

Furthermore, the concept of Industry 4.0 is manifesting itself in CNC machining. This new era is characterized by the interconnectivity of machines and systems, allowing real-time data exchange and decision-making. CNC machines equipped with IoT (Internet of Things) capabilities can monitor their performance and predict maintenance needs, thereby substantially decreasing downtimes. Such predictive maintenance ensures that the automotive manufacturing process remains consistent and highly efficient, ultimately resulting in lower production costs for automotive companies.

Another significant trend is the growing utilization of advanced materials in CNC machining processes. Lightweight materials, such as carbon fiber and aluminum alloys, are increasingly being adopted in automotive applications to improve fuel efficiency and overall vehicle performance. CNC machining allows for precise shaping and finishing of these materials, making it easier for manufacturers to achieve the specific design requirements necessary for modern vehicles. Additionally, the development of composite materials could further revolutionize automotive parts, leading to enhanced durability and resistance to wear and tear.

As the automotive manufacturing landscape evolves, the aforementioned trends will not only boost efficacy in CNC machining but will also foster innovation, driving manufacturers to develop more reliable and efficient vehicles. The integration of these future trends is poised to redefine the boundaries of automotive production, showcasing the potential of CNC machining in an increasingly competitive industry.

Case Studies of Successful CNC Machining in the Automotive Sector

CNC machining has emerged as a transformative technology in the automotive sector. The following case studies illustrate how various manufacturers have successfully integrated CNC machining to address unique challenges while enhancing their production capabilities.

One notable case involves a leading automotive manufacturer that sought to improve the precision of engine components. The company faced issues related to dimensional accuracy and variability in parts, which were critical for performance. By implementing advanced CNC machining techniques, the manufacturer was able to create more precise engine components with significantly tighter tolerances. This shift not only led to enhanced vehicle performance but also reduced waste and scrap rates, achieving a 20% cost reduction in the manufacturing process.

Another compelling case study showcases an electric vehicle (EV) manufacturer that required lightweight, high-strength parts to optimize efficiency. Traditional manufacturing methods often resulted in heavier components that hindered performance. The manufacturer turned to CNC machining to produce intricate, complex geometries from advanced materials such as aluminum and composites. This innovation allowed them to develop parts lighter than their counterparts while maintaining superior strength. Consequently, the manufacturer reduced the overall weight of their EVs, leading to improved range and energy efficiency.

Furthermore, a luxury automotive brand faced challenges in maintaining consistency across limited-run vehicles. The production of bespoke components often resulted in longer lead times and higher costs. By utilizing CNC machining, the brand was able to produce custom parts rapidly while ensuring quality and consistency across its production line. The implementation of CNC solutions facilitated a turnaround time decrease by 40%, achieving both operational efficiency and customer satisfaction with timely deliveries.

These case studies highlight the diverse applications of CNC machining within the automotive industry. From enhancing the precision of critical components to enabling the production of lightweight parts and improving operational efficiencies, CNC technology has proven to be an invaluable asset for manufacturers striving to innovate and excel in a competitive market.

Conclusion: The Impact of CNC Machining on Automotive Parts Manufacturing

CNC machining has emerged as a fundamental technology in the automotive industry, reshaping the landscape of parts manufacturing. This advanced process allows for the production of highly precise components, an essential requirement in the fast-evolving automotive sector. As vehicles become more sophisticated, integrating features such as electric propulsion and advanced safety systems, the demand for precision-engineered parts continues to grow. CNC machining stands at the forefront by providing the accuracy and repeatability necessary to meet these modern automotive demands.

Moreover, CNC machining enhances the efficiency of the manufacturing process. Traditional methods are increasingly being replaced due to their limitations in producing complex geometries and tight tolerances. CNC technology significantly reduces production times while improving part quality, thus decreasing waste and cost. This efficiency translates into quicker turnaround times for manufacturers, ultimately benefiting the consumer with reduced transition times from concept to market. With these advancements, CNC machining not only supports current automotive needs but also aligns with future trends towards sustainability and innovation.

The ongoing investment in CNC technologies signifies a commitment to advancing automotive manufacturing capabilities. As new techniques and materials are developed, CNC machining will likely become even more integral to producing high-performance components and environmentally friendly vehicles. The automotive industry, in its transition toward electric and autonomous vehicles, will benefit immensely from the precision and adaptability that CNC machining can offer. Looking ahead, collaboration between automotive engineers and CNC experts will be crucial in driving this revolution forward, fostering innovation and ensuring that manufacturers can meet the challenges of the future.

Contact me to get the best price.Work with me and I will support you to make more profit.

Welcome your inquiry.

Whatsapp:+86 18912662699

Email:gu@wanledecnc.com

Our website:https://wanledecnc.com/