The Future of Manufacturing: Innovations in Turning Injection Molding

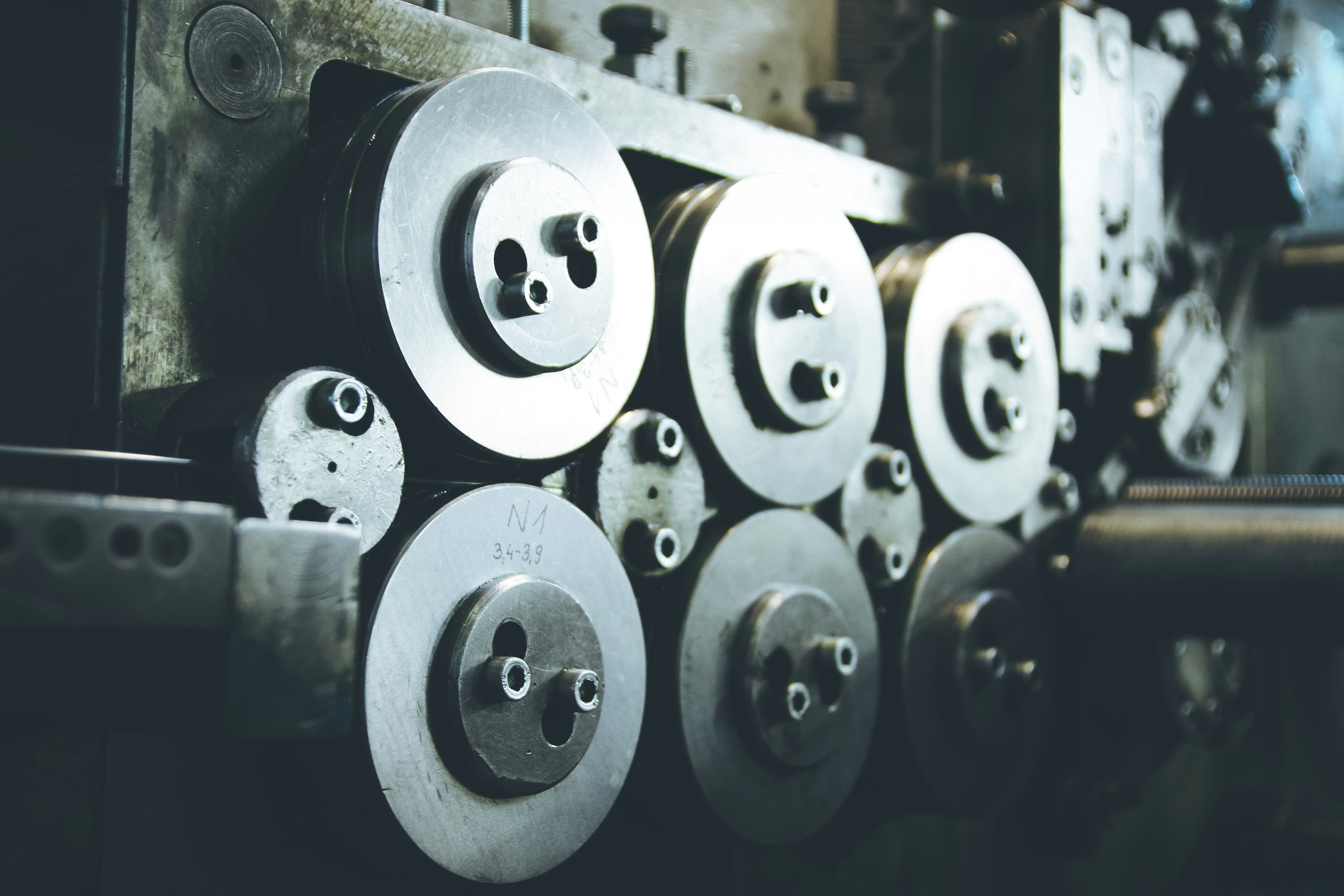

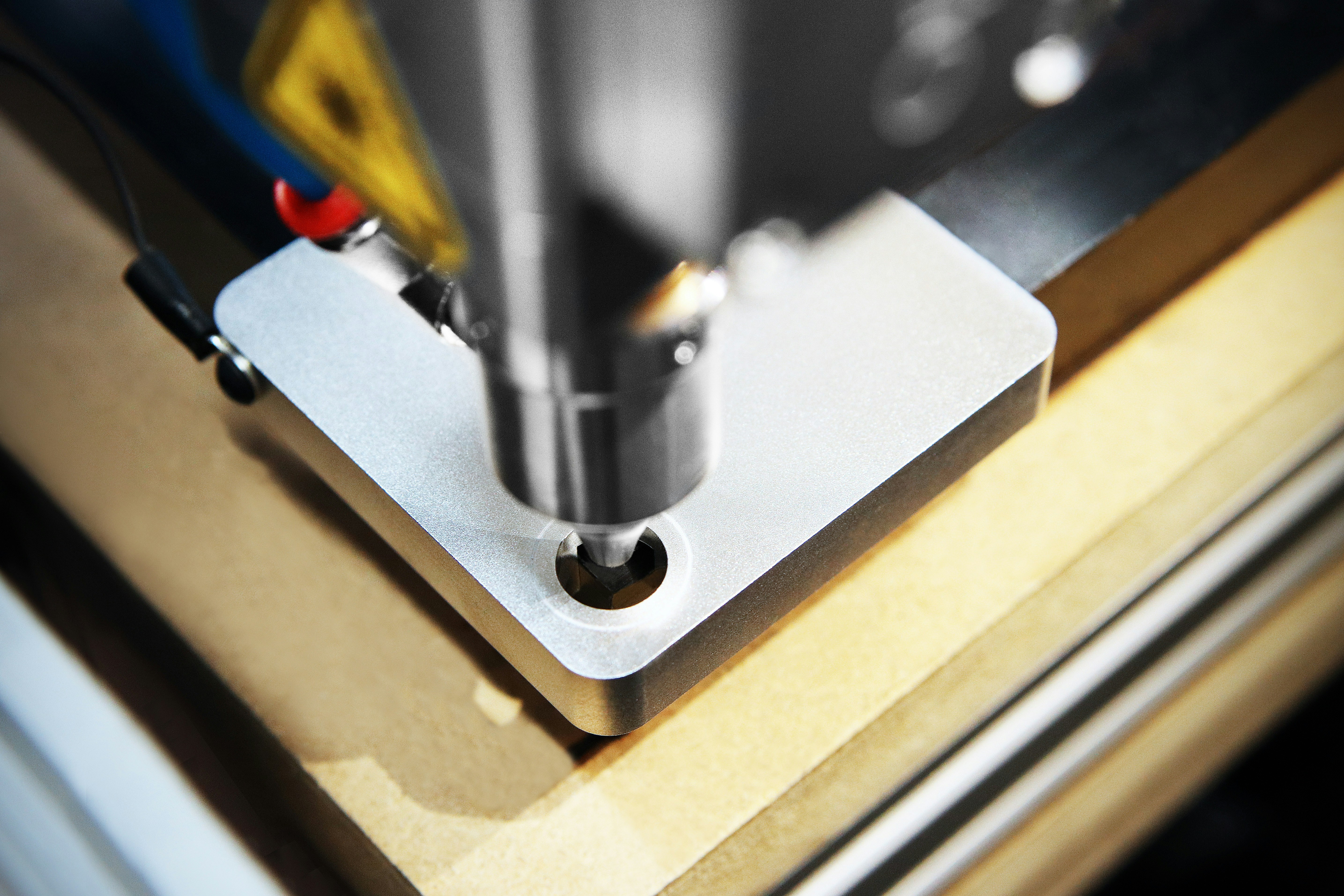

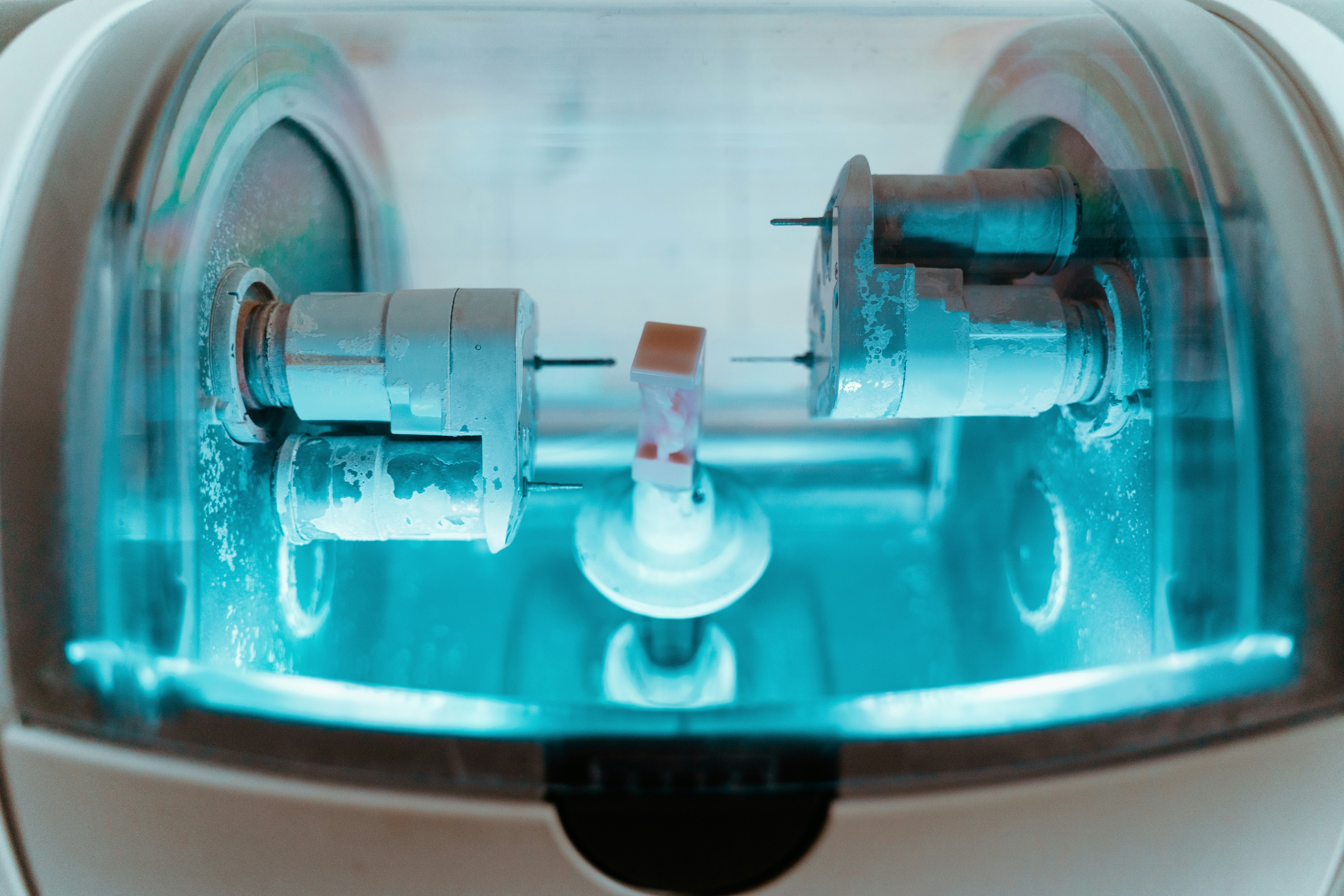

Introduction to Injection Molding Injection molding is a manufacturing process that involves injecting molten material into a mold to create parts or products. This technique has become a cornerstone of modern manufacturing due to its efficiency and ability to produce high volumes of accurate, intricate parts. The origins of injection molding can be traced back […]

The Future of Manufacturing: Innovations in Turning Injection Molding Read More »