Understanding Optical Parts and Their Applications

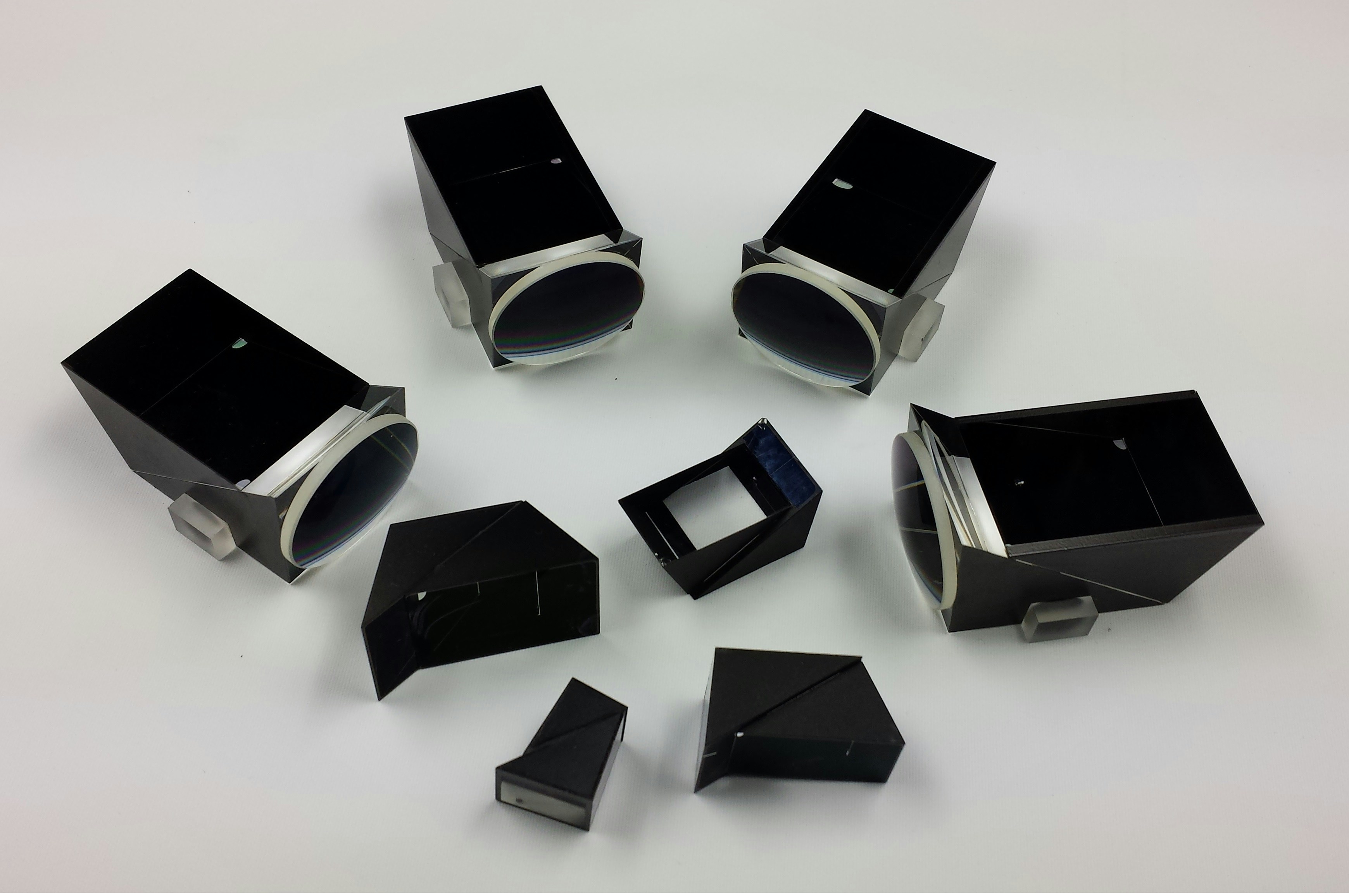

Optical parts are fundamental components utilized in a myriad of applications, particularly in the fields of telecommunications, healthcare, and consumer electronics. These components, which include lenses, prisms, and mirrors, are designed to manipulate light in various ways, enabling the efficient transmission, modification, and reception of optical signals. The precise functionality of these optical parts hinges significantly on the properties of the materials from which they are fabricated, primarily glass and polymers. Each material exhibits distinct optical characteristics, such as refractive index and dispersion, which directly influence the performance of the assembled components.

In telecommunications, optical fibers rely on well-engineered optical components to transmit data over long distances with minimal loss. Lenses are particularly crucial in focusing and collimating light, thereby enhancing the efficiency of data transmission. The healthcare sector leverages optical parts in diagnostic and surgical equipment, where precision optics like mirrors and lenses are essential for accurate imaging and procedures. For instance, endoscopes utilize a combination of optical components to deliver high-quality images from within the human body, allowing for effective diagnosis and treatment.

Consumer electronics have also seen a significant evolution in the incorporation of optical parts. Modern devices such as smartphones and cameras employ advanced lenses and mirrors to enhance image quality and performance. The optical performance of these components is paramount, as consumers increasingly demand high-resolution imaging features. This creates a growing market for high-quality optical components that must be processed with exacting precision.

The processing of optical parts involves sophisticated techniques to ensure that the desired optical properties are met. As industries continue to expand, the necessity for superior-quality optical components becomes more critical, warranting ongoing advancements in the processing technologies for these essential materials. The rise of industries reliant on precision optics emphasizes the importance of understanding the fundamental properties and applications of optical parts.

Key Processing Techniques for Optical Parts

Optical parts manufacturing involves various processing techniques that play a critical role in determining the quality and performance of the final product. Among the most essential techniques are grinding, polishing, coating, and laser cutting, each with its distinct advantages and applications.

Grinding is a fundamental technique used to shape optical components to precise dimensions. This process utilizes abrasive materials to remove material from the surface of the optical parts. The level of precision achieved through grinding is crucial, especially for lenses and mirrors that require specific curvatures for optimal optical performance. While grinding can yield high accuracy, it also has limitations, such as potential surface damage and the need for subsequent polishing to achieve the desired finish.

Polishing follows grinding and serves to enhance the surface finish of optical parts. This technique employs finer abrasives and often includes the use of polishing compounds to achieve a reflective surface. The polishing process is essential for optical components, especially lenses, as it directly affects light transmission and clarity. However, achieving uniformity across larger components can be challenging and requires careful control of parameters such as pressure and speed.

Coating is another crucial technique in optical parts processing, involving the application of thin films to enhance functionality. Optical coatings can provide benefits such as anti-reflective properties, reduction of glare, and increased durability. The complexity of coating application methods, such as vacuum deposition or sputtering, can influence the performance of the coated parts. While coatings significantly improve the performance of optical components, they may also require special handling and environmental considerations during application.

Finally, laser cutting has become an increasingly popular method in the manufacturing of optical parts. This technique utilizes focused laser beams to cut materials with high precision and minimal mechanical stress. Laser cutting is especially advantageous for generating complex geometries and shapes in optical components. Despite its advantages, it is essential to manage the heat affected zone to prevent altering the optical properties of the materials being processed.

In conclusion, understanding the various processing techniques used in optical parts manufacturing is vital for optimizing the quality and performance of optical components. Each method, whether it is grinding, polishing, coating, or laser cutting, contributes uniquely to the final product’s functionality and effectiveness in its intended application.

Innovative Technologies in Optical Parts Processing

The field of optical parts processing has witnessed significant advancements driven by innovative technologies. Among these, automation plays a pivotal role in enhancing both precision and efficiency in the manufacturing process. The introduction of Computer Numerical Control (CNC) machines has revolutionized manufacturing capabilities, allowing for the precise shaping and molding of optical components. These machines, which operate on pre-programmed software, enable manufacturers to produce intricate designs with a high degree of accuracy, ultimately leading to improved product quality and consistency.

In addition to CNC machines, the use of robotic arms in optical parts processing has become increasingly prevalent. These robotic systems are designed to handle complex tasks that would otherwise require extensive human labor. They can perform repetitive and detailed operations, such as assembly and quality inspection, with remarkable speed and precision. By integrating robotics into manufacturing workflows, companies can optimize production rates and allocate human resources to more strategic tasks, thus enhancing overall operational efficiency.

Additionally, the development of new materials and surface treatments has transformed the optical components landscape. Anti-reflective coatings, for instance, are now essential in minimizing light reflection on lenses, ensuring greater light transmission and improved visual clarity. Such advancements enable optical parts to perform better under varied lighting conditions and enhance the user experience significantly. Moreover, photoresists have emerged as crucial materials in the manufacturing of optical components, as they facilitate the production of intricate patterns necessary for high-quality optics.

These technological innovations collectively contribute to improved production capabilities, enabling manufacturers to meet the growing demand for high-performance optical components. By leveraging automation, advanced materials, and innovative surface treatments, the optical parts processing industry is poised for a future marked by increased efficiency and precision.

Future Trends and Challenges in Optical Parts Processing

The optical parts processing industry is witnessing a transformation driven by emerging trends that prioritize sustainability and the adoption of eco-friendly materials. As consumer awareness regarding environmental issues increases, manufacturers are compelled to integrate greener practices into their production processes. The push towards sustainability includes the utilization of biodegradable materials and the implementation of energy-efficient technologies, thereby reducing the overall carbon footprint of optical products. This trend not only caters to the environmentally conscious consumers but also aligns with regulatory requirements aimed at minimizing environmental impact.

However, balancing sustainability with the high standards of quality expected in optical components poses a significant challenge. Mass production often raises concerns regarding consistency and reliability, which are paramount in the industry. Manufacturers must innovate and refine their processes to ensure that eco-friendly practices do not compromise the quality of optical parts. This requires ongoing research and development efforts, as well as the adoption of advanced technologies such as automation and artificial intelligence. These technologies can streamline production while maintaining the high precision required in the optical field.

Additionally, evolving consumer demands are reshaping the landscape of optical parts manufacturing. Customers today seek personalized and customizable optical solutions, which necessitates a shift away from traditional one-size-fits-all approaches. To meet these shifting expectations, companies must embrace agile manufacturing techniques and invest in flexible production systems that can quickly adapt to varying requirements. This represents a significant challenge for established companies, but it also opens up avenues for innovation and competitive differentiation.

Ultimately, the optical parts processing industry stands at a crossroads, where the need for sustainability, quality assurance, and adaptability to consumer preferences converge. Continuous innovation will be crucial to navigate the complexities of these trends and to address the challenges that arise, ensuring that the future of optical technologies remains bright and forward-thinking.