Introduction to Acrylic Machining

Acrylic, also known as polymethyl methacrylate (PMMA), is a versatile thermoplastic that is widely utilized across numerous industries. Renowned for its clarity and resilience, acrylic boasts a light transmission rate of approximately 92%, making it an ideal substitute for glass in various applications. This lightweight material provides excellent weather resistance, durability, and ease of fabrication, which has led to its widespread adoption in sectors ranging from signage and displays to automotive and aerospace components.

There are several types of acrylic available, each offering distinct properties apt for specific applications. Cast acrylic is known for its superior optical clarity and is frequently favored in applications requiring high visual quality, such as retail displays and aquariums. In contrast, extruded acrylic is more economical and is often used for sheet applications like interior signs and glazing solutions. Additionally, variations such as colored or frosted acrylics can be employed to enhance aesthetics or visual effects in design projects.

The significance of acrylic machining cannot be overstated, as the efficiency and precision of the manufacturing process directly influence the quality of the final product. Various machining techniques, such as laser cutting, CNC routing, and polishing, are essential for achieving desired shapes and finishes in acrylic components. Understanding these techniques is crucial for engineers and manufacturers to optimize production efficiency and material utilization, ensuring that the unique properties of acrylic are fully realized. With its diverse applications and essential role in manufacturing, a comprehensive understanding of acrylic machining is indispensable for professionals across multiple industries.

Understanding Acrylic: Types and Properties

Acrylic, a widely utilized plastic, is known for its exceptional clarity and versatility. It is available in multiple types, primarily categorized into cast acrylic and extruded acrylic. Each type possesses distinct properties that make them suitable for various applications.

Cast acrylic is produced by pouring liquid methyl methacrylate (MMA) into a mold, which undergoes polymerization. This process results in a material with superior clarity, higher optical properties, and fewer internal stresses. Consequently, cast acrylic is often preferred in applications requiring optical precision, such as signage, displays, and aquariums. Furthermore, cast acrylic boasts excellent resistance to UV rays, ensuring that its clarity is maintained even with prolonged exposure to sunlight.

On the other hand, extruded acrylic is created through a continuous process in which MMA is forced through an extruder, resulting in a sheet that is easy to fabricate. Although extruded acrylic is typically more affordable and widely accessible, it may not offer the same level of clarity as its cast counterpart. However, it excels in applications that demand easy thermoforming and machining. Structures like windows and skylights often benefit from extruded acrylic due to its robustness and ease of processing.

Both types of acrylic are marked by remarkable durability, making them highly resistant to shattering compared to traditional glass. This property, combined with their lightweight nature, further enhances their utility in various settings. Additionally, acrylic’s ability to be easily fabricated using common machining techniques adds to its attractiveness; it can be cut, drilled, and shaped to meet specific design requirements.

In summary, understanding the differing types and properties of acrylic is essential for selecting the appropriate material for a given application. The combination of clarity, durability, UV resistance, and ease of processing solidifies acrylic’s position as a preferred choice in many industries.

Machining Techniques for Acrylic

Acrylic, known for its clarity and versatility, requires specialized machining techniques to achieve high-quality results. Among the most popular methods are CNC machining, laser cutting, and routing, each with unique advantages and limitations.

CNC machining involves using computer-controlled machines to cut, shape, and finish acrylic components with remarkable accuracy. This method is highly suitable for intricate designs and produces complex geometries with ease. The precision achievable through CNC machining is unmatched, making it ideal for applications where exact dimensions and fine detail are crucial. However, a potential drawback is the initial investment in machinery and setup, which can be relatively high.

Laser cutting is another effective technique for machining acrylic. This method utilizes a focused beam of light to melt or vaporize the material along a defined path. Laser cutting is known for producing clean edges and intricate patterns without the need for extensive post-processing. Additionally, it is capable of handling projects quickly, reducing production time. Nonetheless, laser cutting may sometimes lead to thermal distortion, particularly at the edges, and requires careful calibration to prevent such issues.

Routing is a more traditional approach that involves using a rotating tool to remove material from the acrylic surface. This method is versatile and can produce both straight and curved cuts. Routing can achieve a smooth surface finish; however, it typically results in a slower processing speed compared to CNC machining or laser cutting. Moreover, care must be taken to avoid tool marks, which can compromise the aesthetic qualities of the finished product.

In conclusion, selecting the proper machining technique for acrylic is essential in achieving the desired precision and quality. Each method offers unique capabilities and limitations, making it crucial for manufacturers to evaluate their specific requirements before proceeding.

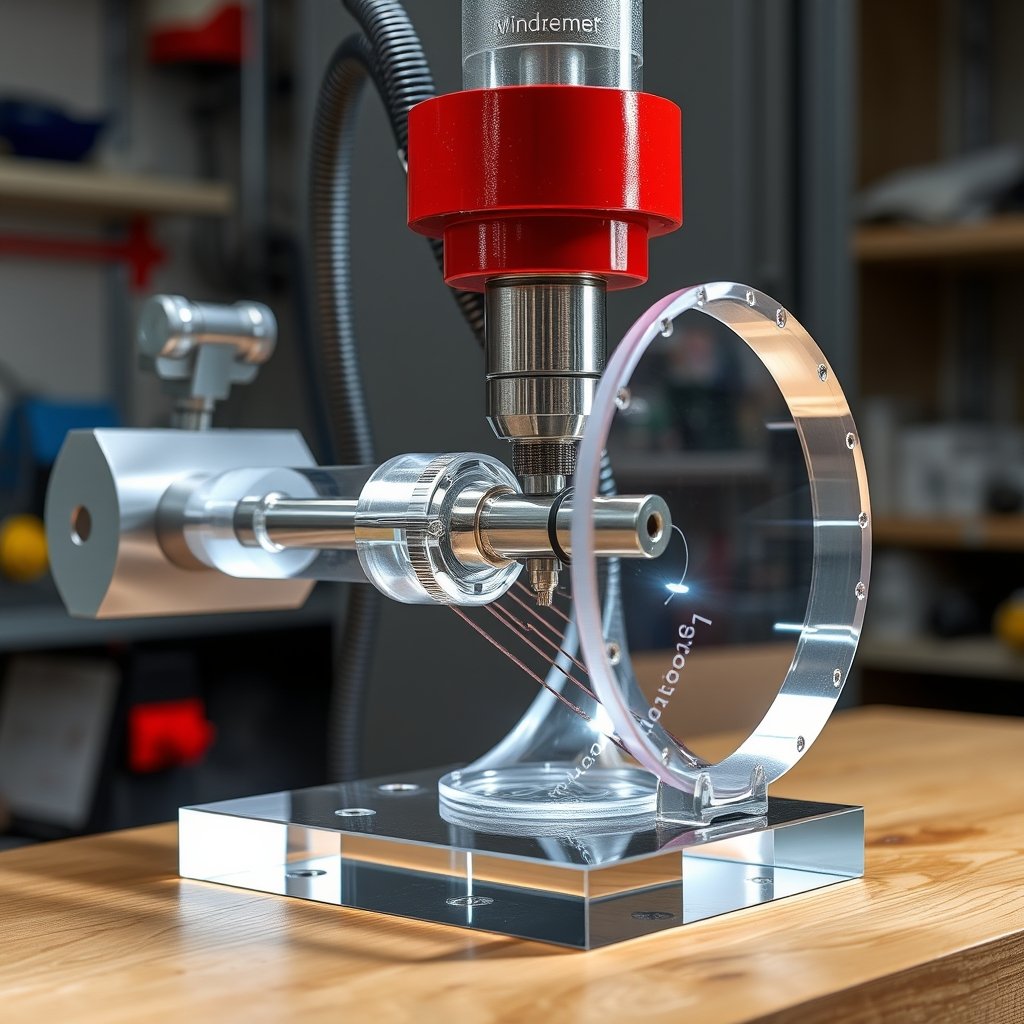

Tools and Equipment for Acrylic Machining

Acrylic machining requires precision and the use of specialized tools to achieve optimal results. Among the most essential tools for this process are drill bits, blades, and CNC machines. Each of these tools plays a critical role in ensuring clean cuts and finely finished edges in the acrylic material.

When it comes to drill bits, selecting the right type for acrylic is crucial. Standard metal drill bits can cause cracking and chipping in acrylic due to their aggressive cutting action. Instead, it is advisable to use bits specifically designed for plastics, such as twist bits or brad-point bits that feature sharp cutting edges and a precise tip. These types of drill bits create a cleaner hole, helping to prevent damage to the edges of the acrylic being machined.

Blades are another significant consideration in acrylic machining. For cutting sheets of acrylic, saw blades with a high tooth count and fine serration are preferred. Table saws, band saws, or jigsaws equipped with specialized acrylic blades will perform exceptionally well. The correct blade reduces the likelihood of melting the acrylic due to friction and ensures that cuts are smooth and accurate, which is essential when aiming for a precise fit in final assembly.

CNC (Computer Numerical Control) machines have revolutionized the way acrylic is machined, offering unparalleled precision and efficiency. When using a CNC machine, it is important to ensure it is equipped with the right tooling, such as specialized end mills or router bits designed for plastics. The machine’s settings, including speed and feed rates, should align with the thickness and type of acrylic to avoid melting and ensure optimal performance.

In summary, the tools and equipment selected for acrylic machining directly influence the quality of the final product. Understanding the specific needs of the acrylic material and the intended machining technique will guide the selection of appropriate drill bits, blades, and CNC machines, leading to effective and successful acrylic machining outcomes.

Best Practices for Acrylic Machining

The machining of acrylic materials requires a strategic approach to ensure optimal performance and quality outcomes. Setting up machinery correctly is the first step in this process. It is essential to use sharp cutting tools specifically designed for acrylic to achieve clean cuts and minimize the risk of chipping. Carbide tools are typically recommended as they provide excellent durability and cutting precision.

When optimizing machine settings, one must consider the speed and feed rate of the machining process. A high spindle speed is generally preferred, as it can produce smoother finishes and reduce the likelihood of melting the acrylic. However, it is vital to strike a balance, as overly high speeds can cause excessive heat and lead to material deformation. Therefore, conducting test cuts on scrap pieces can help determine the most effective settings tailored to the specific acrylic grade being utilized.

Handling acrylic sheets with care is another critical aspect of best practices in acrylic machining. Maintain cleanliness by regularly cleaning the work area and equipment to eliminate dust and debris that may scratch the acrylic surface. Always wear appropriate personal protective equipment (PPE), including safety glasses and gloves, to safeguard against splintered acrylic shards during the machining process.

Implementing safety measures not only protects the operator but also enhances operational efficiency. Regular preventive maintenance of machinery, such as lubricating moving parts and checking for wear and tear, is essential to maintain optimal functioning. By adhering to these best practices, operators can ensure a safe working environment while achieving high-quality results when machining acrylic materials.

Common Challenges in Acrylic Machining and Solutions

Acrylic machining presents several challenges that can affect the quality of the finished product. Among the most common issues encountered are cracking, chipping, and melting of the material. Understanding these challenges is essential for machinists to achieve optimal results and maintain the integrity of acrylic components.

Cracking is one of the primary challenges when working with acrylic. This can occur due to excessive stress, improper tool selection, or inadequate machining speed. To mitigate cracking, it is crucial to use sharp tools specifically designed for acrylic machining. These tools create clean cuts and minimize stress on the material. Additionally, maintaining an appropriate feed rate and cutting speed helps reduce heat buildup, which can lead to crack formation.

Chipping is another issue commonly associated with acrylic machining. This can happen when the cutting tool lacks sharpness or when the machining technique is not properly executed. To minimize chipping, it is recommended to employ up-cut end mills, which assist in pulling the material upwards during the cutting process. Moreover, securing the acrylic sheet firmly to avoid vibration will help enhance surface quality and decrease the likelihood of chipping.

Melting often occurs due to excessive heat generated during the machining process. Acrylic has a relatively low melting temperature, and if not managed correctly, this can lead to a softened or deformed product. To prevent melting, reducing the spindle speed and increasing the feed rate can help distribute heat more efficiently. Furthermore, using coolant or water during machining can significantly assist in managing temperature and improving the integrity of the acrylic.

By understanding these common challenges and implementing effective solutions, machinists can enhance their acrylic machining processes and achieve high-quality results. Awareness of the issues related to cracking, chipping, and melting, along with practical troubleshooting tips, will allow for a smoother machining experience and improved output quality.

Applications of Machined Acrylic Products

Machined acrylic products have found widespread applications across various industries, leveraging their unique properties such as transparency, lightweight nature, and ease of fabrication. One of the most prominent uses of machined acrylic is in the signage industry. Businesses utilize acrylic for creating both indoor and outdoor signs due to its durability and aesthetic appeal. Companies like Starbucks and McDonald’s commonly use illuminated acrylic signs that enhance visibility and attract customers, demonstrating how these products can effectively promote brand identity.

Similarly, in the field of displays, acrylic is highly favored for retail applications. Machined acrylic display cases are often used to showcase merchandise, providing a clear view while protecting products from dust and damage. High-end jewelry stores frequently employ acrylic displays to highlight their items, thus enhancing the shopping experience. The versatility of acrylic also extends to exhibitions, where it is used for creating innovative and engaging display stands that capture attention.

Lighting is another area where machined acrylic products excel. With their ability to diffuse light, acrylic fixtures are frequently employed in both residential and commercial settings. For instance, contemporary lighting designs incorporate acrylic panels and components to achieve a modern look while ensuring efficient light distribution. In museums, acrylic is used to create protective barriers around sensitive exhibits, allowing for illumination without compromising safety.

Additionally, the architectural sector benefits from machined acrylic in various applications such as skylights, facades, and partitions. For example, architects are increasingly employing acrylic sheets in building designs to enhance natural light while maintaining an energy-efficient environment. This trend illustrates the adaptability of acrylic in modern architecture, making it an invaluable resource.

Overall, the diverse applications of machined acrylic products underscore their versatility and effectiveness in multiple industries, exemplifying how innovation in machining techniques can lead to remarkable outcomes in functionality and design.

Environmental Considerations in Acrylic Machining

The process of acrylic machining, while beneficial for various applications, does have notable environmental implications that warrant careful consideration. Acrylic materials, commonly known as polymethyl methacrylate (PMMA), are widely recognized for their versatility and aesthetic appeal. However, the production and machining of acrylic can lead to waste generation, which poses a challenge to sustainable practices.

During the machining process, shavings and cut-offs are often produced, contributing to solid waste. This waste can accumulate, particularly in industrial settings, unless proper management systems are in place. It is essential for organizations engaged in acrylic machining to adopt practices that minimize waste. One effective strategy includes the implementation of closed-loop systems that recycle excess acrylic material, thereby reducing the volume of waste generated. This not only conserves resources but also mitigates the financial burden associated with waste disposal.

Furthermore, many facilities are commencing initiatives aimed at recycling acrylic waste back into the supply chain. This not only addresses waste management issues but also lessens the environmental impact associated with the production of new acrylic materials. Engaging with recycling partners who specialize in acrylic products can streamline this process, allowing businesses to turn potential waste into valuable resources. It is imperative for businesses in this sector to stay informed about local recycling options and the types of acrylic that can be effectively recycled.

The adoption of sustainable practices in acrylic machining further encompasses energy-efficient technologies and techniques. Utilizing modern CNC machinery, for instance, can enhance precision while consuming less energy compared to older models. Thus, companies are encouraged to evaluate their operational processes critically, identifying opportunities for reducing their ecological footprint. In doing so, they not only comply with regulatory requirements but also contribute positively to global sustainability efforts.

Conclusion and Future Trends in Acrylic Machining

In summary, this comprehensive guide has explored the numerous techniques, benefits, and applications of acrylic machining, highlighting its significance across various industries. Acrylic machining offers unparalleled versatility, allowing for the production of intricate designs while maintaining high optical clarity and durability. The primary techniques discussed, such as laser cutting, CNC machining, and precision routing, exemplify the efficiency and effectiveness of acrylic processing.

Looking ahead, the future of acrylic machining is poised for transformative advancements. As industries increasingly seek sustainable and eco-friendly options, potential changes in material formulations are likely to emerge. Researchers are exploring bio-based acrylic alternatives that minimize environmental impact while retaining desirable properties, such as transparency and impact resistance. This shift could lead to a new standard in acrylic materials, aligning with the growing emphasis on sustainable manufacturing practices.

Moreover, innovations in machining technology will further enhance the capabilities of acrylic machining. The integration of artificial intelligence and machine learning into CNC machining processes may lead to greater precision, reduced waste, and increased overall efficiency. Automated systems could significantly streamline production lines, allowing for rapid prototyping and mass customization in various applications, including signage, displays, and consumer products.

As the demand for high-quality acrylic components continues to rise in sectors like automotive, healthcare, and architecture, it is essential for manufacturers to stay informed about the latest trends and technologies. Embracing these advancements not only ensures competitive advantage but also fosters innovation within the industry. The evolution of acrylic machining promises to open new avenues for creativity and functionality, making it a captivating field to watch in the coming years.