Introduction to CNC Machining

Computer Numerical Control (CNC) machining has revolutionized the manufacturing landscape, particularly in the realm of metalworking. This advanced technology employs computer systems to control machine tools, leading to an unprecedented level of precision and efficiency that manual machining methods cannot achieve. CNC machining automates the process of shaping materials, which significantly enhances production capabilities, reduces human error, and increases overall output quality.

One of the most notable materials processed using CNC technology is aluminum. This metal is favored across various industries due to its light weight, strength, and excellent corrosion resistance. CNC machining allows for the intricate shaping of aluminum components, facilitating complex designs and tight tolerances that are essential in today’s advanced applications, from aerospace to automotive and beyond.

The significance of CNC machining lies in its ability to produce parts consistently and accurately, regardless of the scale of the production run. Unlike traditional machining methods, which can fluctuate in quality due to variables such as operator skill and fatigue, CNC systems operate with high repeatability. The integration of CAD (Computer-Aided Design) models with CNC technology ensures that manufacturers can rapidly transition from design to production, minimizing downtime and improving turnaround times.

Moreover, CNC machining optimizes the utilization of raw materials, minimizing waste through precise cutting techniques and efficient nesting strategies. The precision of CNC processes not only streamlines manufacturing workflows but also enhances the longevity and durability of finished products. With further advancements in technology, including multi-axis machining and automated tool changers, the potential applications of CNC aluminum machining continue to expand, making it a keystone in modern manufacturing practices.

Properties of Aluminum for CNC Machining

Aluminum is a widely utilized material in various industries, particularly due to its unique properties that make it especially suitable for CNC machining. One of the most significant characteristics of aluminum is its lightweight nature. Weighing about one-third of steel, aluminum is easier to handle and transport, which can lead to reduced costs in manufacturing and operational processes. This advantage is vital in sectors such as aerospace and automotive, where weight reduction directly contributes to improved performance and fuel efficiency.

Corrosion resistance is another crucial property of aluminum that enhances its suitability for CNC machining. Unlike many metals, aluminum naturally forms a protective oxide layer when exposed to air, which prevents oxidation and deterioration over time. This characteristic ensures that aluminum components maintain their integrity and appearance, making them ideal for applications in harsh environments, such as marine and chemical processing industries.

Moreover, aluminum exhibits excellent machinability thanks to its favorable thermal conductivity and lower cutting forces required during machining processes. These attributes significantly extend tool life and facilitate the production of intricate designs with accuracy. Different aluminum alloys, such as 6061 and 7075, possess varying machinability characteristics. For example, 6061 aluminum is favored for its good mechanical properties and weldability, making it suitable for general structural applications. In contrast, 7075 aluminum, known for its high strength, is widely used in demanding applications like aerospace components.

In summary, the lightweight nature, corrosion resistance, and exceptional machinability of aluminum make it an exemplary material for CNC machining. Furthermore, the diverse array of aluminum alloys available allows manufacturers to choose the most suitable variant according to specific requirements, enhancing the overall efficiency and effectiveness of the machining process.

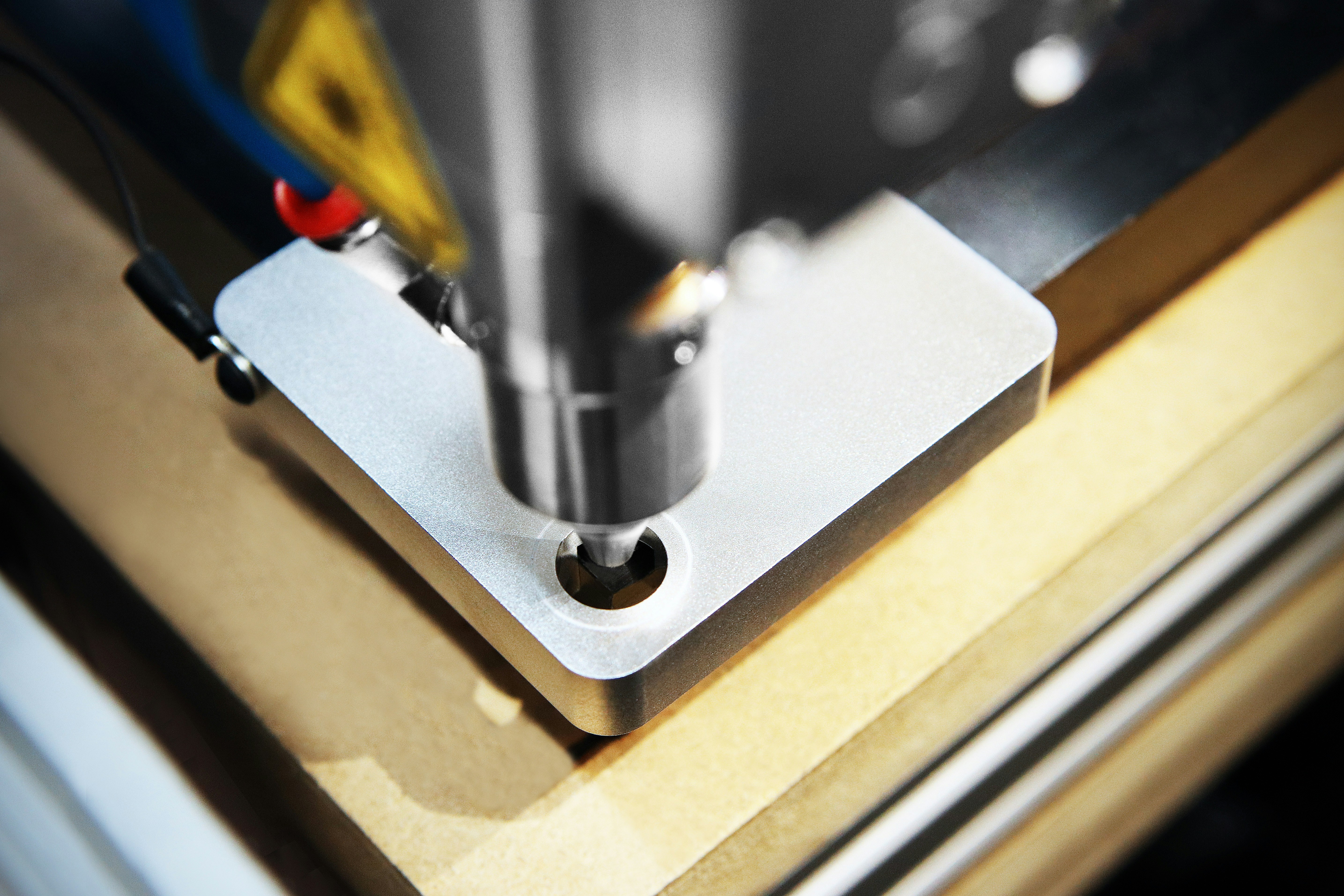

CNC Machining Process for Aluminum

The CNC (Computer Numerical Control) machining process for aluminum is a meticulously organized sequence of steps that ensures precision and efficiency in producing intricate aluminum components. The process begins with the design phase, where engineers utilize CAD (Computer-Aided Design) software to create detailed digital models of the desired parts. This stage is crucial as it establishes the specifications and geometries required for effective machining.

Once the design is finalized, the next step involves programming the CNC machine using CAM (Computer-Aided Manufacturing) software. This software translates the design into a language the CNC machine can understand, generating the necessary code that dictates the machine’s movements and operations. This programming phase is essential as it influences the accuracy and effectiveness of the machining process. Optimizing the toolpaths in the software can significantly reduce machining time while maintaining high levels of precision.

The tooling selection is the third critical stage in the CNC machining process. Choosing the appropriate cutting tools, such as end mills and drills, is vital for successfully machining aluminum. Factors to consider include the type of aluminum alloy, the complexity of the part, and the required surface finish. The right tools not only enhance productivity but also prolong the machine’s life, ensuring consistent quality in production.

Finally, the actual machining stage takes place, where the programmed CNC machine begins to cut the aluminum as per the specifications set in the design and programming phases. The machine executes precise movements, removing material in a controlled manner to achieve the desired shape and finish. This multi-step process underscores the importance of each phase in CNC machining for aluminum, demonstrating how technology aids in producing high-quality components with remarkable accuracy.

Tools and Techniques for CNC Aluminum Machining

In the realm of CNC aluminum machining, the choice of tools plays a pivotal role in achieving precision and efficiency. Various types of cutters are employed, each designed for specific applications and aluminum alloys. Among the most common tools are carbide end mills, which are favored for their durability and ability to maintain sharp edges, allowing for clean, precise cuts. These cutters are particularly effective when machining softer aluminum alloys. Additionally, high-speed steel (HSS) tools may be employed for lighter applications, though they are less common in high-volume scenarios due to their reduced lifespan compared to carbide tools.

Drill bits also carry significant importance in CNC machining. Twist drills are widely utilized for their versatility in boring holes in aluminum. Their design allows for effective chip removal and minimizes the risk of material binding. Furthermore, specially designed drill bits, such as those with a split point, can penetrate deeper and reduce walking on the surface, leading to enhanced accuracy.

The selection of the appropriate tool is crucial, particularly when working with various types of aluminum alloys, each exhibiting distinct characteristics. For example, a machinist may opt for a different end mill type or drill bit based on the alloy’s work-hardening tendency or tensile strength. As such, familiarity with the specific aluminum alloy being processed is essential to select the right tool to ensure optimal machining results.

Equally important are the techniques employed during the machining process. Optimizing parameters such as feed rate, spindle speed, and depth of cut can significantly improve efficiency and prolong tool life. A higher feed rate combined with appropriate speeds ensures that the material is removed effectively without sacrificing surface finish. Careful monitoring and adjustment of these parameters can lead to reduced cycle times and lower production costs, making the machining operation both productive and cost-effective.

Common Applications of CNC Machined Aluminum

CNC machined aluminum is recognized for its impressive versatility and strength, making it suitable for a broad range of applications across various industries. One prominent area where this material excels is in the aerospace sector. Given aluminum’s lightweight nature and excellent strength-to-weight ratio, it is frequently used in the production of aircraft components. These may include fuselage parts, wing skins, and internal structures, where reducing weight is crucial to enhancing fuel efficiency and overall performance.

In the automotive industry, CNC machined aluminum also plays an essential role. Manufacturers leverage its properties to create components that enhance vehicle performance and fuel efficiency. Parts such as engine blocks, transmission housings, and wheel rims are often made from aluminum due to its high thermal conductivity and corrosion resistance. Such features not only contribute to a vehicle’s performance but also extend its lifespan, making aluminum an ideal choice for modern automotive engineering.

The electronics industry similarly benefits from CNC machined aluminum, particularly in the design of components that require heat dissipation. Heat sinks, enclosures, and brackets made of aluminum are common, as they effectively manage heat and protect sensitive electronic parts. The lightweight and durable nature of aluminum also allows for compact designs, which is increasingly important in the era of miniaturization.

Furthermore, consumer products such as sporting goods, appliances, and tools often utilize CNC machined aluminum. Items like bicycles, power tools, and kitchenware all take advantage of aluminum’s lightweight properties along with its resistance to wear and tear. This wide-ranging applicability across multiple sectors underscores the pivotal role of CNC machined aluminum in contemporary manufacturing processes and product design.

Advantages of Using CNC for Aluminum Machining

CNC (Computer Numerical Control) machining has gained immense popularity in the manufacturing sector, particularly when it comes to machining aluminum. One of the primary advantages of using CNC for aluminum applications is the enhanced precision it offers. CNC machines operate with high accuracy, ensuring that even the most intricate designs can be executed with remarkable detail. This level of precision is critical in industries where tolerances are tight and quality control is paramount, such as aerospace and automotive manufacturing.

In addition to precision, CNC machining provides exceptional repeatability. Once a program is set and tested, the machine can replicate the same machining process repeatedly without deviations. This consistency is especially advantageous for producing large quantities of identical aluminum components, allowing manufacturers to maintain quality standards while optimizing production efficiency.

Furthermore, CNC machining significantly reduces production times compared to traditional manual machining methods. Automated processes can operate continuously, resulting in quicker turnaround times for projects. This efficiency not only leads to higher productivity but also allows businesses to meet tight deadlines and respond rapidly to market demands.

Another noteworthy benefit of CNC machining for aluminum is the ability to create complex shapes and designs that would be difficult or impossible to achieve manually. The advanced capabilities of CNC machines enable them to execute complicated geometries, including intricate cuts and three-dimensional contours, with ease. This versatility opens up a wide range of possibilities for product designers and engineers, allowing for innovative solutions that leverage aluminum’s lightweight yet strong properties.

Overall, the advantages of CNC machining for aluminum, including precision, repeatability, fast production times, and complex shape creation, position it as a superior choice in various manufacturing applications.

Challenges and Considerations in CNC Machining of Aluminum

CNC machining of aluminum presents several challenges that manufacturers must navigate to ensure precision and quality in their final products. One of the primary concerns in this process is tool wear. Aluminum, while softer than many other metals, can still lead to significant tool degradation, especially when machining at high speeds or using inappropriate cutting tools. The choice of tool material, geometry, and coatings directly impact the tool’s lifespan and machining effectiveness. It is essential for operators to monitor tool performance and replace or recondition tools as necessary to maintain quality.

Another critical factor in CNC aluminum machining is machining accuracy. Maintaining tight tolerances is vital, especially for components that will be assembled with other parts. Various factors can influence accuracy, including machine calibration, tool alignment, and the setup of the workpiece. Implementing regular maintenance schedules and calibrating CNC machines can substantially enhance machining precision, leading to better-fitting components and reduced rework.

Additionally, managing thermal effects is crucial during aluminum machining. The friction generated during the cutting process can produce significant heat, which may affect both the material properties of the aluminum and the performance of the cutting tools. Excessive heat can lead to thermal expansion of components, affecting the accuracy of machining operations and potentially leading to warping or other defects. To mitigate thermal issues, operators can employ techniques such as optimized cutting speeds, adequate coolant application, and toolpath strategies that minimize heat accumulation.

By addressing these challenges, manufacturers can enhance the CNC machining process of aluminum, resulting in superior quality components. Continuous evaluation and adaptation of machining strategies based on these considerations are essential for successful aluminum fabrication.

Future Trends in CNC Aluminum Machining

The landscape of CNC aluminum machining is continuously evolving, driven by advancements in technology and shifting market demands. One of the most significant trends is the increasing integration of automation into the machining processes. Through the use of robotic systems and automated workstations, manufacturers are able to enhance productivity and consistency. This automation not only streamlines operations but also reduces the risk of human error, thereby increasing the precision of aluminum components.

Another impactful trend is the application of artificial intelligence (AI) in CNC machining. AI algorithms can analyze vast amounts of data from machining operations, enabling manufacturers to optimize cutting parameters in real time. This results in greater efficiency and reduced waste, ultimately contributing to cost savings. Moreover, AI can help in predictive maintenance, allowing for the timely detection of equipment issues before they lead to costly downtimes. The adoption of AI solutions is expected to become more prevalent as companies seek competitive advantages in an increasingly automated market.

Innovations in material technology also play a crucial role in shaping the future of CNC aluminum machining. Lightweight and high-strength aluminum alloys are being developed to meet the demands of industries such as aerospace and automotive. These new materials require specialized machining techniques and more advanced tools, further driving research and development in the sector. Additionally, the exploration of additive manufacturing may lead to hybrid processes combining traditional CNC methods with 3D printing, offering unprecedented design flexibility and material efficiency.

In light of these trends, it becomes clear that the future of CNC aluminum machining is set to be characterized by greater efficiency, reduced costs, and enhanced capabilities. As manufacturers continue to adopt these innovative technologies, the industry will likely witness transformative changes that redefine standard practices and expand the possibilities for aluminum applications.

Conclusion: The Importance of CNC Aluminum in Modern Manufacturing

In recent years, the significance of CNC aluminum machining has escalated, reflecting its crucial role in the evolution of modern manufacturing. The precision, efficiency, and versatility offered by computer numerical control (CNC) technology have revolutionized the way aluminum components are produced, making them indispensable across various industries, including aerospace, automotive, and electronics.

The ability to achieve intricate designs with high tolerances enables manufacturers to create components that meet stringent standards. CNC aluminum machining not only enhances productivity but also reduces waste, contributing to more sustainable manufacturing practices. As industries continue to demand customization and rapid turnaround times, the relevance of CNC machining becomes ever more pronounced.

Ongoing innovations in CNC aluminum machining are pivotal for adapting to enhanced production requirements. The technologies are continually evolving, with advancements in automation, artificial intelligence, and additive manufacturing techniques further establishing the effectiveness of aluminum machining processes. Such improvements allow for increased operational efficiency, more complex designs, and the ability to produce lightweight yet durable components that are essential in today’s high-performance applications.

To remain competitive, manufacturers must prioritize the continual improvement of their CNC machining practices, ensuring they are equipped to respond to the unique needs of diverse sectors. The integration of advanced materials and sophisticated CNC systems not only maintains high-quality production but also fuels innovation, propelling the industry forward.

The ongoing development in CNC aluminum machining confirms its lasting impact on modern manufacturing, underlining its importance as a critical component. As new technologies emerge, it is vital for stakeholders to embrace these advancements to harness the full potential of CNC aluminum, ensuring progress and adaptability in an ever-evolving market landscape.