Introduction to Optical Parts Machining

Optical parts machining is a specialized manufacturing process focused on creating high-precision components essential for optical applications. The significance of this technique extends across various industries such as aerospace, telecommunications, and medical devices. As technology advances and the demand for advanced optical systems increases, the production of precision optical parts has emerged as a critical area of development.

At its core, optical parts machining deals with the fabrication of components like lenses, mirrors, and prisms that influence light behavior. The primary principles involve cutting, grinding, and polishing materials such as glass and specialized ceramics, ensuring that the surfaces are flawless and meet stringent optical specifications. Achieving the required geometrical tolerances and surface finish is paramount, as even minor imperfections can lead to significant degradation in optical performance.

The increasing reliance on high-quality optical components in industries such as aerospace reflects the pivotal role of advanced optics in enhancing safety and efficiency. For instance, advanced optical systems are integral to aircraft navigation and communication devices. Similarly, within the telecommunications sector, optical fibers and related components enable high-speed data transmission, making robust and precise optical parts crucial for modern infrastructure.

In the medical field, optical components play a vital role in diagnostic equipment and surgical instruments. The demand for precision optical parts that facilitate clearer imaging and enhanced functionality has spurred innovations in machining processes, allowing manufacturers to meet the rigorous standards required for these applications.

As industries continue to evolve, the need for sophisticated optical parts machining techniques remains an imperative pursuit. The intersection of innovation and precision in this domain is reshaping the landscape of optical technologies, thereby underscoring the importance of understanding effective machining processes.

Key Materials Used in Optical Parts Machining

Optical parts machining involves the precise fabrication of components that play crucial roles in various fields, including telecommunications, healthcare, and manufacturing. Among the key materials employed in this process are glass, ceramics, and polymers, each offering unique properties that make them suitable for optical applications.

Glass materials, such as borosilicate and optical glass, are favored for their exceptional light transmission capabilities and stability. They possess a high refractive index, allowing for efficient lens performance. Additionally, glass exhibits remarkable resistance to environmental factors, such as temperature fluctuations and chemical exposure. However, machining glass poses challenges due to its brittleness and the risk of surface cracking, necessitating the use of specialized tools and techniques to achieve the desired precision without compromising the material’s integrity.

Ceramics, including materials like aluminum oxide and zirconia, are also prominently used in optical parts machining. Ceramics are known for their high durability, excellent temperature resistance, and low thermal expansion, making them ideal for applications requiring stability under varying conditions. Their rigidity allows for the creation of finely detailed features in optical components. However, similar to glass, machining ceramics can be complex due to their hardness. The use of advanced machining techniques, such as laser cutting or diamond grinding, is usually required to yield high-quality results.

Furthermore, polymers, such as polycarbonate and acrylic, have become increasingly popular due to their lightweight nature and ease of machining. These materials are typically easier to shape and mold compared to glass and ceramics. They possess good light transmission properties and are often used in applications where shatter resistance is critical. Nonetheless, the susceptibility of polymers to scratching and UV degradation must be addressed through appropriate coatings and treatments during the machining process. Each material presents its own set of challenges and advantages, necessitating a thorough understanding of their properties for optimal optical parts machining.

Machining Techniques for Optical Components

The production of optical components requires precision and intricate processes that are tailored to achieve the desired specifications. Several machining techniques, namely grinding, polishing, and laser machining, play crucial roles in creating high-quality optical parts.

Grinding is one fundamental technique used in optical machining. This method employs abrasive wheels to remove material from the surface of the optical component. The grinding process can create a variety of surface finishes and geometries, making it versatile for different optical applications. Tools such as diamond grinding wheels are often used to ensure a high level of precision. However, grinding can introduce surface irregularities if not controlled properly, necessitating subsequent processes like polishing to enhance the optical quality.

Polishing is another vital technique. It is designed to achieve the fine surface finish that optical components require. This process employs fine abrasives to refine the surface, eliminating any minor irregularities left from grinding. Tools involved in polishing may include cloth wheels and cerium oxide for achieving a high gloss finish. One of the primary advantages of polishing is its ability to enhance light transmission through the optical materials. Nevertheless, it can be time-consuming and requires careful monitoring to avoid overshooting the desired specifications.

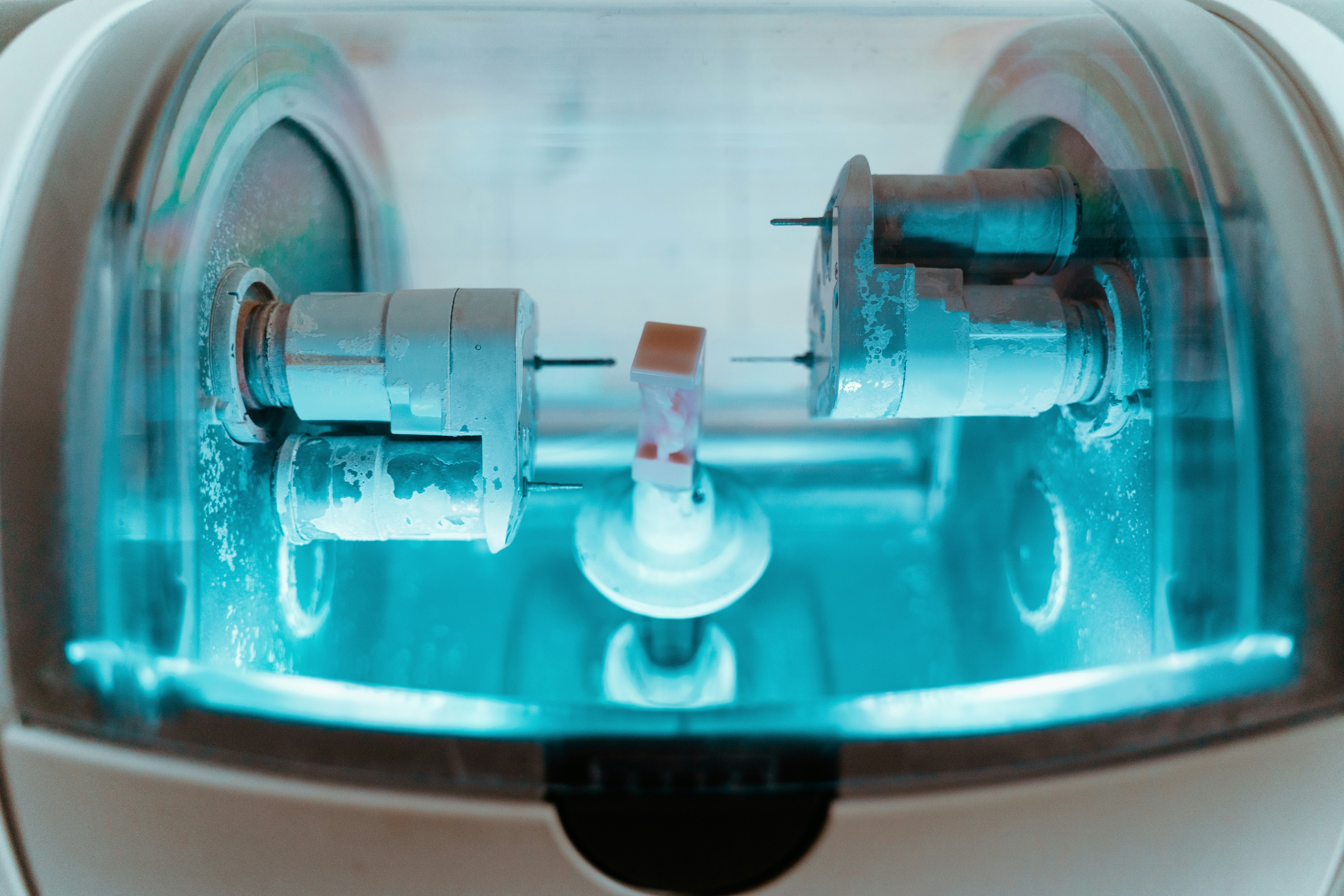

Laser machining has emerged as a modern alternative for producing optical components, particularly for intricate designs that cannot be easily achieved through traditional methods. This technique utilizes high-energy laser beams to remove material with precision. The advantage of laser machining lies in its ability to produce complex geometries quickly and with minimal heat-affected zones. Although often considered a costlier method, the precision and speed it offers may justify the investment in certain applications.

In summary, grinding, polishing, and laser machining are essential techniques in the fabrication of optical components, each offering distinct advantages and limitations that should be considered when selecting the appropriate method for specific optical designs.

Quality Control in Optical Parts Machining

The realm of optical parts machining necessitates a rigorous approach to quality control to ensure the precision and functionality of manufactured components. Given the critical role optical parts play in various applications, engineers employ a multitude of measures and standards to uphold quality throughout the entire machining process. This involves meticulous planning, monitoring, and testing at each stage to guarantee that the components meet stringent performance expectations.

One essential measure in quality control is the assessment of surface roughness. This characteristic significantly influences the optical performance of components, as it affects light transmission and reflection properties. Engineers utilize specialized equipment, such as surface profilometers, to quantitatively analyze the texture of the produced surfaces. The surface roughness is meticulously controlled to adhere to predefined standards, ensuring that the optical characteristics remain intact, thereby optimizing the functionality of the end products.

Another critical aspect is the testing of the refractive index. This measurement is vital as it directly impacts the light’s behavior as it passes through optical materials. Instruments like interferometers are commonly employed for this purpose, allowing engineers to measure refractive indices with high precision. Maintaining a consistent refractive index across various batches of production is imperative for ensuring reliable performance in practical applications.

Interference testing methods also play a crucial role in the quality assurance process. These techniques help identify minute defects and deviations in optical components that could compromise their effectiveness in real-world environments. Engineers often employ interferometric testing to visualize surface quality and determine adherence to design specifications.

Ultimately, the implications of quality control in optical parts machining extend beyond the manufacturing floor. High-quality components lead to superior performance in various applications, from consumer electronics to scientific instruments. Therefore, maintaining strict quality standards is essential to deliver products that meet or exceed industry expectations.

Challenges and Solutions in Optical Parts Machining

Machining optical parts presents a unique set of challenges that can significantly impact the quality and precision of the final product. One of the primary challenges in this domain is the formation of surface defects. Any imperfection on the surface of an optical component, such as scratches or pits, can lead to a substantial decline in optical performance, affecting factors like transmission, reflection, and overall image quality. Thus, manufacturing processes must be carefully controlled to minimize these defects, particularly in the final polishing stages.

Maintaining tight tolerances is another critical hurdle in optical parts machining. Optical components often require exceptionally precise dimensions, with tolerances in the order of micrometers. Achieving such precision necessitates the use of sophisticated machining techniques and tools, such as computer numerical control (CNC) machines equipped with specialized optics capabilities. Continuous monitoring and adjustment during the machining process are essential to ensure that dimensional specifications are met without compromising optical clarity.

The brittleness of common optical materials, such as glass and certain ceramics, adds complexity to the machining process. These materials are prone to chipping or cracking when subjected to traditional machining techniques. To mitigate this risk, newer technologies, such as laser machining and ultra-precision diamond turning, have gained popularity. These methods not only enhance precision but also reduce material stress during machining, thereby preserving material integrity.

Advancements in technology also play a vital role in overcoming these challenges. The integration of artificial intelligence and machine learning into the machining process has proven beneficial, as these technologies can predict potential issues before they arise, allowing for real-time adjustments. Enhanced tooling solutions, including diamond-coated tools that provide superior wear resistance, further contribute to improved production quality and efficiency in optical parts machining.

Applications of Machined Optical Parts

Machined optical parts play a vital role in numerous industries, providing the precision and quality required for effective performance in various applications. One of the most prominent areas where these components are utilized is in camera systems. The high-quality lenses and prisms, made through intricate machining processes, ensure clarity and sharpness in images, benefitting both amateur and professional photographers alike. This precision is crucial for modern cameras, which often integrate complex optical features such as autofocus and image stabilization, further enhancing user experience.

Another significant application of machined optical parts is found in microscopes. Optical components like objectives and ocular lenses are meticulously crafted to deliver unparalleled magnification and resolution, enabling scientists and researchers to explore the microscopic world with remarkable accuracy. This is especially important in medical and biological fields, where clear visualization of specimens can lead to important discoveries and advancements in diagnostics and treatment.

Telescopes also rely heavily on machined optical parts. Components such as mirrors and lenses are manufactured to exact specifications to facilitate the observation of distant celestial objects. The precision in machining optical elements ensures that telescopes can gather more light, thus providing clearer and more detailed images of planets, stars, and galaxies. This application not only aids astronomers in their research but also enhances the experience for amateur stargazers.

Moreover, laser systems extensively use machined optical components to direct and focus laser beams accurately. In industries ranging from manufacturing to telecommunications, precision machined optics play an essential role in ensuring effective operation and safety. The development of high-quality optical parts facilitates the advancement of laser technology, further driving innovations across multiple sectors.

Each of these applications underscores the importance of precision machining in the production of optical components, which ultimately leads to improved performance and technological advancements across industries.

Future Trends in Optical Parts Machining

The field of optical parts machining is poised for significant advancements in the coming years, driven by new materials, automation, robotics, and additive manufacturing techniques. These innovations are set to enhance precision, efficiency, and versatility within the industry, thus reshaping how optical components are produced.

One of the most exciting trends is the increasing utilization of advanced materials. As the demand for higher performance optical components grows, the industry is exploring versatile materials such as polymer optics, glass ceramics, and nano-coatings, which allow for improved durability and optical quality. These materials enable manufacturers to meet diverse application requirements across sectors, including telecommunications, aerospace, and healthcare.

Complementing the shift in materials is the rise of automation and robotics in optical parts machining. Automated processes can significantly reduce production times and costs while improving accuracy and consistency. The integration of artificial intelligence (AI) with robotics not only facilitates finer adjustments during machining but also enables predictive maintenance, minimizing downtime. This trend demonstrates a significant move towards smart manufacturing practices that enhance operational efficiency and adaptability in production environments.

Moreover, additive manufacturing is gaining traction as an alternative to traditional machining methods. 3D printing technologies allow for the rapid production of complex optical geometries with reduced waste, paving the way for custom solutions that were once deemed impractical. The ability to manufacture intricate designs on-demand will greatly benefit industries looking to innovate rapidly while adhering to sustainability goals.

As these trends converge, the future of optical parts machining will be characterized by enhanced capabilities and solutions that address the evolving needs of various industries. It is imperative for companies to stay abreast of these developments to maintain a competitive edge in this dynamic landscape.

Case Studies: Successful Optical Parts Machining Projects

Optical parts machining is a sophisticated field that involves the precise fabrication of components used in a variety of applications, from lenses to prisms. Examining successful projects can provide insights into the challenges faced and the strategies employed to overcome them. Below, we explore several notable case studies that exemplify excellence in optical parts machining.

One prominent case involved the production of high-precision lenses for an aerospace application. The initial challenge was achieving exceptional surface quality, as the lenses were required to maintain stringent optical specifications to ensure proper functionality in high-altitude environments. To address this, the team employed advanced CNC machining techniques, coupled with specialized coatings, that minimized surface irregularities. The successful completion of this project not only met the aerospace standards but also demonstrated the feasibility of using innovative machining methods for producing optical components under complex requirements.

Another noteworthy project featured the grinding and polishing of custom prisms utilized in medical imaging equipment. The challenge was the need for tight tolerances and minimal light scattering to improve image clarity. To achieve this, the machining team implemented a systematic approach that involved iterative testing and adjustments to eliminate defects. They also explored new abrasives and polishing techniques, which led to an enhanced finish on the prisms. Ultimately, the project significantly improved the equipment’s performance, showcasing how adaptive machining practices can result in superior optical parts.

Lastly, a case involving the manufacture of a unique optical filter for scientific research illustrates another aspect of optical parts machining. The initial difficulties arose from the filter’s specific wavelength requirements, demanding precise material selection and thickness. The team utilized laser machining and multi-layer coating technologies to ensure that the final product not only met the designated specifications but also led to advancements in research capabilities. This case demonstrates the versatility of machining techniques in addressing specialized optical needs.

Conclusion

In the rapidly evolving landscape of technology, optical parts machining has emerged as a pivotal discipline, vastly impacting numerous industries ranging from telecommunications to healthcare. Throughout this blog post, we have explored the diverse techniques and processes integral to machining optical components, emphasizing their significance in enhancing product performance and accuracy. The precision required in crafting optical elements such as lenses and mirrors cannot be overstated, as these parts play a vital role in the functionality of optical systems.

Additionally, we have addressed the challenges faced by professionals in this field. Issues such as material selection, the intricacies of surface finish, and maintaining tight tolerances are critical factors that machinists must navigate. The continuous demand for improved optical performance in devices amplifies the urgency for innovative machining solutions. Thus, the development of advanced machining technologies and techniques remains essential in overcoming these obstacles. For instance, innovations such as ultra-precision machining and computer-controlled processes represent significant advancements that enhance efficiency and accuracy in producing optical components.

As industries grow increasingly reliant on optical technologies, the importance of mastering optical parts machining cannot be overlooked. It serves not only as a foundation for various applications but also as a catalyst for future innovations that aim to push the boundaries of what is technologically possible. The pursuit of excellence in optical machining practices encourages ongoing research and development, highlighting the dynamic nature of this field. Ultimately, understanding the nuances of optical parts machining will empower professionals to contribute to the ever-expanding horizons of technology, ensuring a continuous forward momentum in precision optics.

I went over this website and I think you have a lot of excellent information, saved to my bookmarks (:.

Do you have a spam issue on this site; I also am a blogger, and I was curious about your situation; we have created some nice methods and we are looking to swap techniques with others, please shoot me an email if interested.