Introduction to Optical Parts Machining

Optical parts machining is a specialized process that involves the fabrication of components essential for the manipulation and control of light. This field plays a pivotal role in several high-tech industries, such as telecommunications, aerospace, and medical technology. As the demand for advanced optical systems continues to grow, the significance of precise optical parts machining becomes increasingly pronounced. The ability to manufacture optical components with high precision directly influences the performance and reliability of systems in these sectors.

In telecommunications, optical components are crucial for the development of fiber optics and photonic devices. These components facilitate high-speed data transmission, enabling the modern communication infrastructure that supports everything from internet services to mobile communications. Similarly, in the aerospace sector, optical parts are integral for navigation systems, satellite imaging, and environmental monitoring. The reliability and accuracy of these optical devices can significantly impact the safety and efficiency of aerospace operations.

Moreover, in the medical technology field, optical components are essential in various diagnostic and therapeutic devices, such as endoscopes, imaging systems, and laser treatment equipment. The precision of optical machining directly affects the functionality and effectiveness of these medical devices, which can have substantial consequences for patient care and medical efficacy. However, the machining of optical parts presents unique challenges, including the need for high tolerance levels, surface finish quality, and material selection.

As this guide progresses, it will delve into the primary objectives and challenges associated with optical parts machining, highlighting best practices and innovations in the field. Understanding these aspects is crucial for professionals and companies striving to excel in the dynamic landscape of optical component production.

Understanding Optical Materials

Optical parts machining relies heavily on the selection of suitable materials, as these directly influence the performance and durability of optical components. The three predominant materials utilized in the manufacture of optical components are glass, plastic, and ceramics, each exhibiting unique properties that suit different applications within the optical industry.

Glass is one of the most traditional materials used for optical components. Its excellent transparency to a range of wavelengths and exceptional optical properties, such as low dispersion and high refractive index, make it an ideal choice for lenses and prisms. Furthermore, the machinability of glass can be optimized through the application of specific grinding and polishing techniques, which enhance its surface quality. However, glass can be prone to chipping and cracking during machining, necessitating careful handling and precise tools.

In contrast, plastic materials, such as acrylic and polycarbonate, provide an alternative to glass with their lightweight and impact-resistant qualities. These materials exhibit less brittleness than glass, translating to easier machining processes. With advancements in polymer technology, certain plastics can match the optical quality of glass while being easier to mold into complex shapes, making them suitable for applications where design flexibility is crucial. However, factors such as thermal expansion and sensitivity to UV degradation must be considered when selecting plastic for optical applications.

Ceramics represent another category of materials that offer unique benefits for optical system fabrication. With high hardness and durability, ceramics can withstand extreme conditions, making them suitable for challenging environments. The machining of ceramics, however, can be more complex due to their brittleness, necessitating specialized tools and techniques. The high refractive index of certain ceramics enhances their capability in optical applications, particularly in high-performance or specialized optical systems.

Choosing the right material for optical parts machining is integral to achieving optimal performance. Each material’s specific properties dictate its suitability based on the optical design requirements, the intended application, and the machining processes involved.

Machining Techniques for Optical Components

Machining optical components requires precision and finesse, given the stringent standards dictating optical performance. Several techniques are employed in the manufacture of these parts, each offering unique advantages, limitations, and applications.

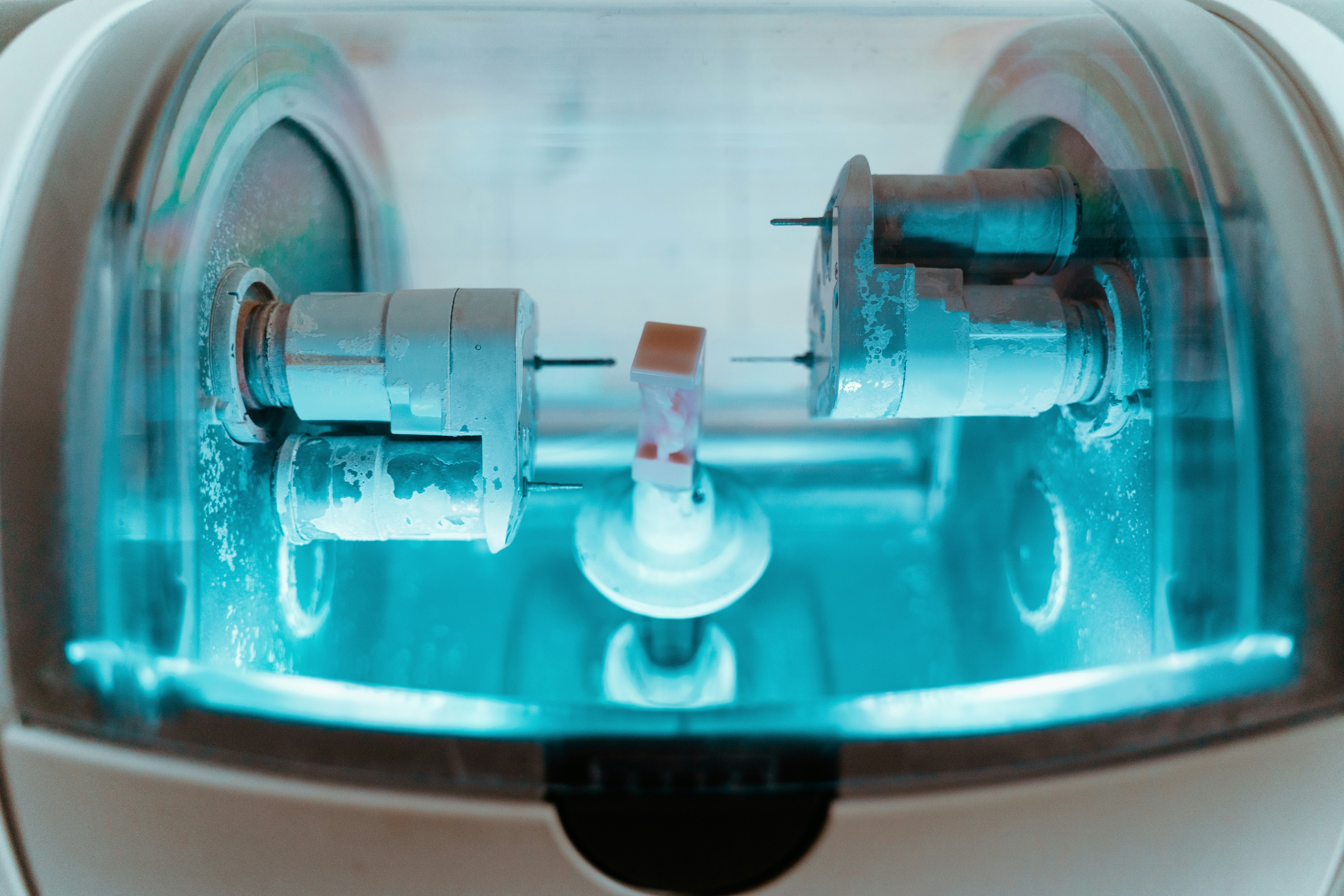

Grinding is a fundamental technique used to achieve the desired shape and finish on optical components. It involves the use of abrasive wheels or belts to remove material. This method is particularly effective for generating complex geometries needed in lenses and mirrors. The main advantage of grinding lies in its ability to shape materials quickly and with high accuracy. However, it may introduce surface roughness, necessitating subsequent polishing to obtain a flawless finish. Typical applications include the initial shaping of glass lenses and prisms.

Polishing is a critical process for enhancing the optical quality of components. This technique uses fine abrasive materials, either in a slurry or on a soft pad, to create a smooth, reflective surface. The primary advantage of polishing is its capacity to improve transmittance and reduce scattering, which is vital for applications in cameras, microscopes, and telescopes. The limitation of polishing, however, is that it cannot significantly alter the shape of the component; it is more suited for final finishing. Sustained control of the polishing process is essential to avoid material removal that leads to distortion.

Laser processing represents a modern approach to machining optical parts. This technique utilizes focused laser beams for various applications, including cutting, engraving, and surface modification. The precision of laser processing allows for intricate designs and fine details to be achieved without physical contact. Its main advantage is the ability to process a wide range of materials, notably those difficult to machine using traditional methods. However, the initial investment in laser technology can be substantial, making it less accessible for small-scale operations. Typical applications include the creation of complex optical patterns and micro-features on lenses and filters.

Precision Measurement in Optical Machining

Precision measurement is a critical component in the field of optical machining, as it directly impacts the quality and performance of the optical components produced. Establishing exact tolerances is essential for ensuring that finished parts meet the stringent requirements of optical applications. To achieve this precision, a variety of sophisticated tools and technologies are employed, including interferometry and optical metrology.

Interferometry is one of the most widely used techniques in optical machining. This method leverages the principles of wave interference to measure the geometric characteristics of optical parts with remarkable accuracy. By analyzing the interference patterns produced when coherent light waves interact, it is possible to detect even the smallest deviations from the desired dimensions. This technique plays a vital role in assessing surface flatness and figure, which are crucial for optical performance.

Optical metrology encompasses a range of technologies designed to measure the parameters of optical components accurately. These include methods that monitor surface roughness, curvature, and alignment. High-end optical measurement systems can analyze the entire surface of a component, providing insights into micro-level variations that could affect optical performance. The integration of advanced data processing software allows for real-time adjustments during the machining process, enhancing both speed and accuracy.

Despite the advancements in precision measurement technologies, challenges remain. Factors such as environmental conditions, equipment calibration, and human error can all contribute to inaccuracies. Special measures must be undertaken to mitigate these risks, including regular calibration of measuring instruments, maintaining stable measurement environments, and thorough training for operators.

Overall, the importance of precision measurement in optical machining cannot be overstated. As the demand for high-quality optical components continues to grow, the development and refinement of measurement techniques will be paramount in meeting industry standards and customer expectations.

Quality Control in Optical Parts Production

Quality control is a critical aspect of optical parts machining, ensuring that the components produced meet rigorous industry standards. The complexity of optical components necessitates precise inspection techniques and protocols tailored to their specific characteristics. During the machining process, various measurements and tests are conducted to assess the dimensional accuracy, surface quality, and optical performance of the parts. This includes the use of advanced equipment such as coordinate measuring machines (CMM), interferometers, and optical profilers, which provide essential data about the components’ attributes.

One of the primary objectives of quality control in optical parts production is to detect defects early in the manufacturing process. Common defects include scratches, pits, or aberrations that can significantly impact the component’s performance. Non-destructive testing methods, such as visual inspections, laser scanning, and surface roughness testing, play a pivotal role in identifying these issues without compromising the integrity of the parts. By implementing such measures, manufacturers can ensure that only components meeting the criteria are forwarded for final assembly.

Moreover, adherence to established quality standards, such as ISO 9001, is crucial. These standards guide manufacturers in creating effective quality management systems that govern all phases of production, from the initial design to post-production assessments. Continuous monitoring through statistical process control (SPC) helps maintain a consistent quality level across production runs. Implementing feedback loops where data gathered from inspections are analyzed facilitates the ongoing improvement of machining processes.

In summary, the effectiveness of quality control measures in optical parts machining cannot be overstated. Through a combination of precise inspection techniques, adherence to industry standards, and proactive defect detection, manufacturers can achieve high-quality optical components that meet the evolving demands of the industry. This systematic approach not only enhances product reliability but also strengthens customer confidence in the optical parts produced.

Recent Advances in Optical Machining Technology

In recent years, there has been a significant evolution in optical machining technology, largely due to advancements in CNC machining, automation, and the development of innovative materials. These innovations have been instrumental in enhancing efficiency, precision, and overall quality in the manufacturing of optical components.

CNC (Computer Numerical Control) machining has become increasingly sophisticated, allowing for greater accuracy and repeatability in the crafting of optical parts. New algorithms and software have enabled complex geometries to be machined with extreme precision, thereby meeting the stringent tolerances often required in optical applications. For instance, the use of 5-axis CNC machining has expanded the capabilities of manufacturers, allowing them to produce intricate shapes and curves that were previously challenging or impossible to achieve.

Automation plays a crucial role in the latest optical machining advancements. The integration of robotics and automated systems reduces human error and minimizes production time, enabling manufacturers to produce optical components at a higher rate. Automated quality control systems are another noteworthy development, employing advanced sensors and machine learning algorithms to inspect parts during production. This process significantly improves the consistency of products while minimizing waste through precise adjustments made on-the-fly.

Moreover, advances in material science have led to the introduction of new composites and polymers specifically designed for optical applications. These materials often exhibit superior optical properties and durability compared to traditional materials, which grants manufacturers greater flexibility in their product designs. Case studies show successful implementations of such materials in the creation of high-performance lenses and other optical components that demand reliable performance under varying conditions.

Overall, the recent advances in optical machining technology provide a solid foundation for enhancing the production of high-quality optical components, setting the stage for future innovations within the industry.

Applications of Optical Parts Machining

Optical parts machining plays a pivotal role across various industries, contributing significantly to the precision and performance of numerous applications. One of the prominent sectors benefiting from this technology is telecommunications. High-performance optical components, such as lenses and prisms, are essential for fiber optic systems, which enable rapid data transmission over long distances. For instance, companies in this field utilize optical machining techniques to produce components that enhance signal quality and reduce losses, thereby boosting the efficiency of communication networks.

Another key area where optical parts machining excels is in the medical device industry. Here, precision optical components, including endoscopic lenses and surgical optics, are crucial for enhancing visualization during procedures. Techniques such as diamond turning and CNC machining facilitate the manufacturing of high-quality optical elements that meet stringent medical standards. These advancements not only improve the performance of medical devices but also contribute to patient safety and surgical outcomes by providing clearer images and better precision.

Consumer electronics also heavily rely on optical parts machining. With the rise of augmented reality (AR) and virtual reality (VR) technologies, there is an increasing demand for high-definition optics in devices like smartphones and gaming systems. Optical machining enables the production of lightweight, compact, and high-resolution lenses that significantly enhance user experience. For example, companies invest in optical machining to create display windows and camera lenses that optimize performance while minimizing distortion and color aberration.

Aerospace is yet another industry that utilizes optical parts machining for critical applications. Components such as sensors and camera systems are essential for navigation and surveillance. The precision achieved through optical machining ensures that these parts operate effectively under extreme conditions. The ability to create intricate, lightweight designs with enhanced optical properties leads to improved performance and reliability in aerospace technologies.

Challenges in Optical Parts Machining

Optical parts machining is a sophisticated process that presents numerous challenges, which can significantly impact the quality and precision of the final product. A primary challenge in this field is managing manufacturing tolerances. Optical components require tight tolerances to ensure proper functionality, particularly in applications such as telecommunications and medical devices. Even minor deviations can lead to substantial performance issues, necessitating rigorous quality control processes throughout the machining workflow.

Another significant challenge arises from material limitations. Optical materials, including glass and certain plastics, exhibit unique properties that can complicate the machining process. These materials may be brittle, making them prone to cracking or chipping during machining operations. Additionally, the choice of material can influence the effectiveness of the machining technique employed, making it imperative to understand the material characteristics and select suitable tools and methods accordingly.

Ensuring surface quality is also a crucial aspect of optical parts machining. The surface finish is critical for optical components as it affects light transmission and reflection properties. Imperfections such as scratches or uneven surfaces can interfere with optical performance. To mitigate such issues, advanced finishing techniques and careful handling during production are essential. Employing techniques such as polishing and coating can enhance surface quality, ensuring the optical parts meet required specifications.

To overcome these challenges, it is important to adopt best practices in optical parts machining. Implementing proper equipment maintenance, utilizing high-quality tools, and continuously training personnel can help improve machining accuracy and production efficiency. Additionally, integrating state-of-the-art technologies, such as computer-aided design (CAD) and computer numerical control (CNC) machining, can streamline processes and enhance precision, thereby facilitating better outcomes in the production of optical components.

The Future of Optical Parts Machining

The landscape of optical parts machining is poised for significant transformation as we move into the next decade. Emerging technologies, such as artificial intelligence (AI) and machine learning, are expected to play a crucial role in revolutionizing manufacturing processes. These technologies can enhance precision and efficiency, leading to faster production cycles and reduced errors. As manufacturers adopt AI-driven systems, they can anticipate machine failures before they occur, optimizing maintenance and minimizing downtime, which is essential for the high-stakes environment of optical components.

Market demands are also a driving force behind the evolution of optical parts machining. The rise in industries requiring advanced optics, such as telecommunications, aerospace, and healthcare, indicates a robust need for more sophisticated optical components. As these sectors advance, they require manufacturers to produce parts with higher complexity and tighter tolerances. This shift will prompt the adoption of advanced machining techniques, including additive manufacturing and precision micro-machining, which will enable the production of intricate designs that traditional methods may struggle to achieve.

Furthermore, sustainability practices are becoming increasingly integral to manufacturing. The optical parts machining industry must address environmental concerns and embrace eco-friendly practices. This includes the implementation of energy-efficient machinery, the reduction of waste through new materials and methods, and the recycling of optical components at the end of their life cycle. By prioritizing sustainability, manufacturers not only meet regulatory requirements but also align with consumer expectations for environmentally responsible production.

In summary, the future of optical parts machining is set to be characterized by high-tech innovations, heightened market demands, and a commitment to sustainable practices. Companies that invest in these areas will likely lead the industry, offering enhanced capabilities and meeting the evolving needs of their clients effectively.