Introduction to Swiss CNC Machining

Swiss CNC machining, also known as Swiss-type turning, is a specialized manufacturing process that has gained significance in the production of precision components. This method originated in Switzerland in the late 19th century, initially designed for the production of small, intricate parts such as watch components. Its unique approach to machining allows for the creation of highly detailed and accurate parts, making it a preferred choice for numerous industries, including aerospace, medical, and electronics.

The hallmark of Swiss CNC machining lies in its capability to perform multiple operations on a single setup. The machine’s design allows the workpiece to move while the cutting tool remains stationary or vice versa, facilitating the creation of complex geometries with exceptional accuracy. Traditional machining methods usually require multiple setups and tool changes, potentially compromising the integrity of the part and increasing production time. In contrast, Swiss CNC machines streamline this process, substantially reducing machining time while enhancing precision and consistency.

Another distinguishing feature of Swiss CNC machining is the ability to maintain tolerances of just a few microns. This characteristic is particularly vital in industries such as medical device manufacturing, where precision is paramount for functionality and patient safety. The importance of Swiss machinery extends beyond mere precision; it also plays a crucial role in materials efficiency, minimizing waste and optimizing resource usage throughout the production process.

In summary, Swiss CNC machining represents a significant advancement in manufacturing technology, characterized by its ability to produce intricate, high-quality components with remarkable accuracy. This method stands as a reliable solution for industries demanding high precision and consistency in their parts, reinforcing its status as a leading machining technique in today’s competitive market.

How Swiss CNC Machines Work

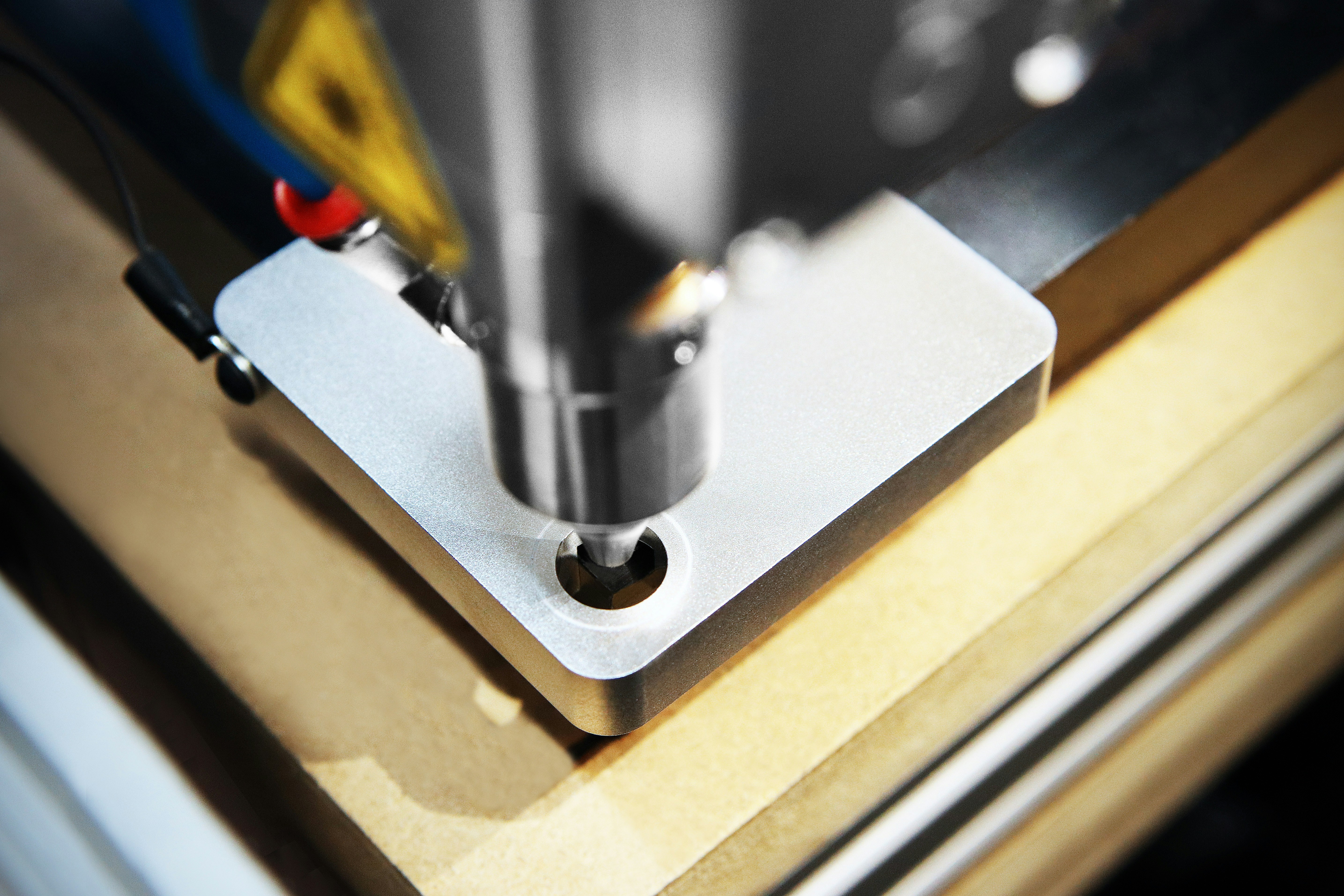

Swiss CNC machines are renowned for their remarkable precision, particularly in producing complex parts. The fundamental operating principle relies on a unique architecture, optimized for high-speed machining and extreme accuracy. Central to their functionality is the sliding headstock system, which allows the workpiece to move along the Z-axis during the machining process. This feature reduces the distance between the cutting tool and the material, minimizing vibrations and enhancing the quality of the finished product.

The design of a Swiss CNC machine typically includes several key components. Firstly, the spindle plays a vital role in rotating the cutting tool, sustaining high RPMs that contribute to efficient material removal. Spindles are often equipped with advanced bearings to ensure stability and precision during operation. Additionally, the tool holders are designed to accommodate various types of cutting tools, allowing for quick and easy changes that enhance productivity and versatility in machining operations.

Another critical aspect of Swiss CNC machines is the guideways, which ensure smooth movement of the sliding headstock and other moving components. Made from hardened materials, these guideways reduce friction and wear, thereby extending the lifespan of the machine. Furthermore, many modern Swiss CNC machines incorporate linear guides and ball screw mechanisms to achieve superior accuracy and repeatability.

The combination of these elements enables Swiss CNC machines to execute intricate designs with tight tolerances, which are essential in industries such as aerospace, automotive, and medical. The ability to perform multiple operations simultaneously—turning, milling, and drilling—significantly streamlines the manufacturing process, further underscoring the advantages of this technology. Overall, understanding the operational mechanics of Swiss CNC machines is critical for achieving optimal machining results in precision manufacturing.

Benefits of Swiss CNC Machining

Swiss CNC machining, also known as Swiss turning, offers a multitude of advantages over conventional manufacturing techniques. One of the most significant benefits is its exceptional precision. Swiss CNC machines are designed to achieve incredibly tight tolerances, often within a few microns. This level of accuracy is crucial for industries such as aerospace, medical, and automotive, where even the slightest deviation can compromise safety and performance. For example, in the production of medical components, the high precision of Swiss machining ensures that parts fit perfectly and function as intended.

Another notable advantage is the reduced cycle times associated with the Swiss CNC machining process. Unlike traditional methods that may require multiple setups and tools, Swiss machines operate with a single setup, which diminishes the time required to switch tools and positions. Consequently, this streamlined approach results in significantly faster production cycles. In industrial applications, this efficiency leads to increased output and shorter lead times, making it an attractive option for manufacturers facing high demand.

The ability of Swiss CNC machining to handle complex geometries also sets it apart from other techniques. These machines employ a sliding headstock that allows for the creation of intricate shapes and features while maintaining stability and precision. This capability is particularly beneficial in the fabrication of components with complicated designs, such as those found in watchmaking or intricate electronic devices. A real-world example can be seen in the production of precision watch components where complex shapes are essential for functionality. Here, Swiss CNC machining excels in producing detailed elements without compromising quality.

In summary, the benefits of Swiss CNC machining include high precision, reduced cycle times, and the capacity to handle complex geometries and tight tolerances, making it a favorable choice for various demanding industries.

Applications of Swiss CNC Machining

Swiss CNC machining has garnered significant attention across multiple industries due to its precision and efficiency. This method is particularly renowned for producing intricate components with tight tolerances, making it indispensable in sectors such as medical, automotive, aerospace, and tooling.

In the medical industry, Swiss CNC machining is used to manufacture surgical instruments, implants, and intricate components that require high precision. Items such as orthopedic screws and dental implants benefit from this machining process, as it ensures the required geometric shapes and surface finishes are achieved, essential for patient safety and effectiveness.

The automotive sector also relies heavily on Swiss machining technology. It is instrumental in creating parts like fuel injectors, valve bodies, and various engine components. The ability to produce complex geometries with minimal waste makes Swiss CNC machining a preferred choice for manufacturers aiming to enhance performance while reducing production costs.

Another critical area is the aerospace industry, where components must meet stringent safety and performance standards. Swiss CNC machining is ideal for creating lightweight yet durable parts such as brackets, gears, and housings for aircraft. Its capabilities allow for the production of intricate designs that contribute to improved aerodynamics and overall efficiency.

Moreover, tooling is another area where Swiss CNC machining demonstrates its strengths. Toolmakers utilize this technology to produce high-precision tools for various applications. Components like dies, molds, and drills are crafted with exceptional accuracy, ensuring high performance and longevity during usage.

In conclusion, the versatility and precision of Swiss CNC machining make it a strategic choice across multiple industries, facilitating the creation of high-quality components integral to modern manufacturing processes.

Materials Suitable for Swiss CNC Machining

Swiss CNC machining is renowned for its precision and capability to work with a diverse array of materials. Among the most commonly utilized metals are stainless steel, aluminum, and brass. Each of these materials possesses unique properties that make them suitable for different applications in the manufacturing industry.

Stainless steel is particularly favored for its strength, corrosion resistance, and durability. It is often employed in industries such as aerospace, medical devices, and automotive components where precision is critical. The ability of Swiss CNC machines to achieve fine tolerances transforms stainless steel into intricate parts that meet rigorous quality standards.

Aluminum, another material extensively machined using Swiss technology, offers lightweight and strong alternatives for various applications. It is widely used in sectors like electronics, automotive, and marine, where reducing weight while maintaining structural integrity is essential. The machinability of aluminum allows for high speeds and effective processing, making it an efficient choice for Swiss CNC machining operations.

Brass serves as a preferred choice when a combination of machinability and corrosion resistance is required. Its excellent thermal and electrical conductivity makes it ideal for plumbing, electrical components, and decorative applications. Swiss CNC machining can produce precise brass parts with intricate details, enhancing their functionality and aesthetic appeal.

In addition to metals, plastics and composites are also well-suited for Swiss CNC machining. Materials such as nylon, polycarbonate, and various composite substrates can be machined to tight tolerances, making them ideal for sectors like consumer goods and medical devices. When selecting materials for Swiss CNC machining, factors such as machinability, tensile strength, and required tolerances play a critical role in determining the optimal material for specific applications.

Challenges in Swiss CNC Machining

Swiss CNC machining, while renowned for its precision and efficiency, does present several challenges that operators and manufacturers must confront. One of the most significant issues faced in this domain is tooling wear. Due to the high speeds and tolerances associated with Swiss machines, tools can wear down rapidly, leading to decreased accuracy and increased production costs. Effective maintenance strategies and regular tool replacement schedules are critical to mitigate this issue, ensuring that the consistency of dimensions is maintained over extended production runs.

Another challenge pertains to setup times. The initial setup of Swiss CNC machines can often be time-consuming, primarily when dealing with highly complex geometries or custom workpieces. This aspect can create bottlenecks in production schedules, particularly in environments where quick turnarounds are essential. To address this challenge, optimized setup procedures—including pre-planning and the use of specialized fixtures—can help significantly reduce labor time and improve workflow efficiency.

Programming complexities also constitute a hurdle in Swiss CNC machining. The intricacies of programming, especially for intricate designs or multi-axis machining, can result in longer lead times and increased potential for errors. To counteract these programming challenges, investing in robust software solutions that facilitate easier programming and simulation can prove beneficial. Additionally, training staff on the latest technology and programming techniques plays a vital role in enhancing productivity and reducing error rates.

By recognizing these challenges—tooling wear, lengthy setup times, and programming difficulties—manufacturers can implement best practices and leverage technology to enhance the efficiency of Swiss CNC machining processes. Through proactive management and continuous improvement, the obstacles associated with Swiss CNC machining can be effectively navigated, resulting in higher-quality outputs and greater operational success.

Future Trends in Swiss CNC Machining

As industries evolve, Swiss CNC machining is poised to undergo significant transformations driven by emerging trends and technological advancements. One of the most prominent trends includes the integration of automation within machining processes. Automation enables the enhancement of productivity and efficiency, allowing manufacturers to minimize downtime and maximize output. Furthermore, the use of collaborative robots or cobots is gaining traction, facilitating safer and more effective human-machine interactions in the production environment.

Advancements in software programming also play a pivotal role in shaping the future landscape of Swiss CNC machining. The introduction of sophisticated software solutions streamlines the programming process, making it more intuitive and user-friendly. Manufacturers can now create complex machining programs with greater ease and precision, reducing the time required for setup and enabling quicker turnaround times for projects. This enhances the overall operational agility, allowing CNC machine shops to respond more swiftly to market demands.

The impact of Industry 4.0 is another crucial factor influencing Swiss CNC machining trends. This paradigm shift emphasizes connectivity, data exchange, and smart manufacturing technologies. As machines become increasingly interconnected, data analytics can be leveraged to optimize machining processes, reduce waste, and improve overall production efficiency. The implementation of predictive maintenance techniques enables operators to anticipate equipment failures before they occur, leading to decreased downtime and reduced operational costs.

In light of these trends, the future of Swiss CNC machining hinges on the pursuit of continuous innovation. As manufacturers implement new tools, methodologies, and technologies, the industry must remain adaptable to change. Emphasizing the importance of research and development will be key in staying ahead of the curve in precision machining. By embracing these advancements, companies can position themselves competitively and ensure sustained success in the Swiss CNC machining landscape.

Choosing the Right Swiss CNC Machining Provider

Selecting a trustworthy Swiss CNC machining provider is critical for ensuring high-quality precision components for your projects. As industries increasingly rely on the unique benefits of Swiss CNC machining, the need for reliable service providers has grown more paramount. One of the first factors to assess is the provider’s experience in the industry. Adequate experience often correlates with an understanding of various materials, tolerances, and geometries, which can be instrumental in meeting specific project requirements. Researching a provider’s history and client testimonials can significantly contribute to understanding their expertise.

Next, evaluate the technology capabilities of the machining provider. Swiss CNC machining is known for its advanced technology, such as multi-axis capability and automatic tool changers. Investigating whether a provider utilizes the latest machines and tools can offer insight into efficiency and production quality. Additionally, a commitment to continuous investment in technology often signifies that a provider is dedicated to maintaining a competitive edge and delivering superior results.

Quality assurance processes are another critical aspect to investigate. A reputable Swiss CNC machining provider will have stringent quality control measures in place, such as ISO certifications. This guarantees that components are manufactured with precision and meet or exceed industry standards. Inquire about their inspection techniques and how they ensure the accuracy of finished products.

Lastly, customer service should not be overlooked. A responsive provider is vital in establishing effective communication and support throughout the project lifecycle. Look for companies that demonstrate a willingness to collaborate and address concerns promptly. This aspect can significantly influence the overall experience and outcomes of your machining projects.

Conclusion

In conclusion, Swiss CNC machining represents a pivotal advancement in the field of modern manufacturing, offering unparalleled precision and efficiency. This technique has revolutionized the production of complex components, particularly for industries that demand high tolerances and intricate designs. By utilizing a sliding headstock and a guide bushing, Swiss CNC lathes provide the capability to work with a variety of materials and facilitate the manufacturing of parts with exceptional precision, thereby significantly reducing waste and increasing productivity.

Throughout this guide, we have explored the various aspects that make Swiss CNC machining a preferred choice for manufacturers worldwide. Its core benefits, including the ability to produce small to medium-sized parts with high accuracy, have made it an indispensable tool in sectors such as aerospace, automotive, medical, and electronics. As technology continues to evolve, the integration of advanced software and automation further enhances the capabilities of Swiss CNC machines, making them more adaptable and efficient.

As you consider your component needs, it is crucial to recognize the value that Swiss CNC machining brings to the table. Not only does it ensure quality and consistency in production, but it also opens up possibilities for innovative designs that conventional machining methods may not accommodate. The future of manufacturing is leaning towards more specialized and automated processes, making it essential for businesses to stay updated with these advancements and consider Swiss CNC machining as a viable option for their manufacturing requirements. Embracing this technology may lead to a significant competitive advantage, driving efficiency and precision in your operations.