Introduction to Aerospace Tolerance Tooling

Aerospace tolerance tooling is a vital component in the manufacturing and assembly of aircraft and spacecraft, playing a significant role in ensuring safety and performance. It refers to the precision instruments and methods employed to create and maintain the specific tolerances required in aerospace components. Tolerances dictate the allowable limits of variation in a product’s dimensions, characteristics, or performance, having a profound impact on the overall functionality and reliability of an aircraft. Given the high-stakes nature of air travel, where even the smallest defect can lead to catastrophic results, aerospace tolerance tooling is of the utmost importance.

In the aerospace industry, the production of components requires meticulous attention to detail. Each part must conform to strict dimensional tolerances, which are defined during the design phase. These tolerances ensure that parts fit together seamlessly, allowing for proper assembly and operation. The influence of tooling on the manufacturing process cannot be overstated; it determines the precision with which those tolerances can be achieved. Advanced machining techniques, such as CNC (Computer Numerical Control) machining, are often utilized to facilitate this process, offering enhanced control and minimizing human error.

The significance of aerospace tolerance tooling extends beyond mere production efficiency; it encompasses aspects of quality assurance and regulatory compliance. Rigorous testing and inspection protocols are in place to verify that parts meet established aerospace standards. These may include measuring the tolerances using specialized tools and technologies, ensuring that components can withstand the rigorous demands of flight. Ultimately, the effectiveness of aerospace tolerance tooling in the manufacturing process directly contributes to the safety and performance of aircraft, establishing it as a foundational element of the aerospace engineering discipline.

The Importance of Precision in Aerospace Manufacturing

In the realm of aerospace manufacturing, precision is not merely a beneficial attribute; it is an absolute necessity. The complexities of aerospace systems demand extremely high levels of accuracy during production, as any deviation from established tolerances can result in catastrophic outcomes. Poor tolerances can lead to malfunctions, compromising the safety of both passengers and crew members while in flight. As such, the aerospace industry prioritizes the implementation of stringent precision measures throughout the manufacturing process.

One critical aspect of ensuring precision in aerospace manufacturing is aerospace tolerance tooling. This specialized tooling is designed to measure and maintain tight tolerances that are essential for the performance and reliability of various aircraft components. For instance, if parts such as wing structures or propulsion systems do not fall within specified tolerances, the entire aircraft’s functionality may be jeopardized. Inaccuracies can result in increased wear and tear or even mechanical failures, which could lead to severe accidents in operational scenarios.

Furthermore, the implications of poor precision extend beyond the immediate safety concerns. Financial repercussions are also a significant consideration, as rework or recalls can be exceedingly costly for manufacturing companies. These added expenses stem not only from the direct costs of repairs but also from potential delays in production schedules and reputational damage within a highly competitive market. Investing in aerospace tolerance tooling mitigates these risks by fostering an environment that promotes quality and reliability. Ultimately, the precision achieved through advanced tooling and manufacturing practices reinforces the aerospace sector’s commitment to safety, efficiency, and performance.

Types of Aerospace Tolerance Tooling

Aerospace tolerance tooling is a critical component in the manufacturing process, ensuring precision and reliability in aviation and space industries. Different types of tooling are essential for the various phases of production, each characterized by its unique functions and tolerances. Among the most common types are jigs, fixtures, and gauges.

Jigs are specialized tools used to control the location and motion of parts during manufacturing operations. They provide precise guidance to cutting or drilling tools, ensuring that the aerospace components are manufactured to exact specifications. Jigs are designed to accommodate variations in material and part dimensions, allowing for high repeatability and consistency in production. For example, a wing assembly jig may hold various wing parts in precise alignment to facilitate accurate drilling of holes, maintaining strict tolerances necessary for safe aircraft operation.

Fixtures, on the other hand, are dedicated tools that hold the workpiece in place while machining operations are performed. Unlike jigs, which direct the tools, fixtures solely focus on securing the component without influencing tool paths. In many cases, aerospace manufacturers employ fixtures to maintain the integrity of complex geometries and ensure that pieces remain stable during processes such as welding or assembly. A common application of fixtures is in the assembly of fuselage sections, where they provide stability and accurate positioning for components that require intricate assembly.

Lastly, gauges play a pivotal role in quality control within the aerospace industry. These precision measurement tools are used to verify that parts conform to design specifications. They come in various forms, including plug gauges, go/no-go gauges, and optical gauges, ensuring that tolerances are adhered to meticulously. For instance, a go/no-go gauge may be employed to check whether a drilled hole meets the exact diameter requirements as per aerospace standards, thus safeguarding functional integrity.

Standards and Regulations Governing Aerospace Tolerance

The aerospace industry requires stringent adherence to various standards and regulations to ensure safety, reliability, and efficiency. Several organizations, including the Federal Aviation Administration (FAA) and the International Organization for Standardization (ISO), have established guidelines that govern aerospace tolerances and tooling requirements. These frameworks are critical in shaping industry practices and ensuring that components meet the required specifications for their intended applications.

One of the key standards made by the FAA is the FAR (Federal Aviation Regulations), which outlines the compliance requirements for aviation safety. These regulations dictate specific tolerances that must be adhered to in the design and manufacturing process of aerospace components. The FAA’s guidelines help maintain uniformity across manufacturers, thereby ensuring that every part meets the necessary safety and performance thresholds critical in aerospace applications.

In tandem with FAA guidelines, ISO standards play a pivotal role in establishing a global consensus on quality management in aerospace engineering. Notably, ISO 9001 provides a framework for managing quality across the supply chain, while ISO 5775 addresses the precise measurement and control of tolerances in aerospace tooling. These standards not only enhance the reliability of aerospace components but also facilitate international trade, as adherence to ISO standards is often a requirement for suppliers seeking to work with global aviation companies.

Moreover, industry-specific organizations like SAE International provide additional standards tailored to aerospace applications. These standards incorporate best practices and advanced methodologies that address the complex challenges faced by aerospace manufacturers. By adhering to these rigorous standards, factories can significantly reduce the risks associated with manufacturing defects, ultimately leading to safer aviation operations.

In conclusion, the standards and regulations set forth by organizations such as the FAA and ISO are paramount in governing aerospace tolerances. Their comprehensive guidelines ensure that tooling requirements and industry practices align with the highest safety and quality benchmarks. Organizations that comply with these regulations foster an environment of excellence in the aerospace industry, directly contributing to advancements in aviation safety and technology.

Technological Advances in Tooling for Aerospace Applications

The aerospace industry has witnessed significant technological advancements in tooling, particularly through the incorporation of computer-aided design (CAD), additive manufacturing, and automation. These innovations enhance the precision and efficiency of aerospace tolerance tooling, which is essential for meeting the stringent requirements of aircraft manufacturing and maintenance.

Computer-aided design has transformed the way tooling is conceptualized and developed. With CAD software, engineers can create highly detailed 3D models of tooling components, enabling them to visualize complex geometries and assess performance in a virtual environment. This capability not only shortens the design cycle but also reduces the risk of errors during production, ultimately leading to improved accuracy in manufacturing. CAD technologies allow for precise measurements and adjustments, ensuring that tooling adheres strictly to the necessary aerospace tolerances.

Additive manufacturing, or 3D printing, has emerged as a revolutionary process in the production of aerospace tooling. It enables the creation of intricate tooling designs that may not be feasible through traditional methods. By using materials such as lightweight metals and composites, additive manufacturing provides bespoke solutions tailored to specific aerospace applications. This method also supports rapid prototyping, which significantly cuts down on lead times and provides engineers with the ability to iterate designs quickly based on testing and performance feedback.

Furthermore, automation plays a critical role in enhancing the efficiency of aerospace tooling processes. Automated systems and robotics can perform repetitive tasks with high precision and consistency, leading to a reduction in human error and increased throughput. This enables manufacturers to meet high production demands while maintaining strict quality control standards. The integration of advanced technologies, including the Internet of Things (IoT), allows for real-time monitoring of tooling performance, which helps in identifying potential issues before they arise, thus safeguarding the integrity of the aerospace structures being produced.

Design Considerations for Aerospace Tooling

When it comes to aerospace tolerance tooling, several critical design factors significantly influence its functionality and accuracy. The selection of materials is paramount, as aerospace tooling must withstand rigorous manufacturing conditions while maintaining precision. It is essential to choose materials that offer a combination of strength, lightweight properties, and resistance to wear and temperature variations. Common materials used in aerospace tooling include high-performance alloys, composites, and engineered plastics, which provide the durability needed for complex aerospace parts.

Equally important is the tooling geometry, which must be meticulously designed to meet the specific requirements of the aerospace components being produced. The geometrical configuration of the tooling affects how well it can align and secure components during the manufacturing process. Features such as surface finish, dimensions, and contouring play a vital role in achieving the desired tolerances. These geometric considerations help ensure that every part produced aligns with the strict standards set by the aerospace industry.

In addition to material selection and geometry, adaptability to complex geometries is another crucial factor in the design of aerospace tooling. Modern aerospace components often feature intricate shapes and contours that challenge conventional manufacturing processes. As such, tooling must be designed with the flexibility to accommodate these complexities while still delivering the required precision. This adaptability can involve designing modular tooling that can be quickly reconfigured to meet different production needs or utilizing advanced manufacturing techniques, such as additive manufacturing, to create custom tooling solutions.

Overall, focusing on these design considerations—material selection, tooling geometry, and adaptability—ensures that aerospace tolerance tooling can meet the demanding requirements of the aerospace sector while maintaining the precision necessary for safety and performance in aviation applications.

Best Practices for Maintaining Aerospace Tolerance Tooling

Maintaining aerospace tolerance tooling is critical for ensuring the precision and reliability required in aerospace production. Regular inspection is the first step in this maintenance process. Conducting routine checks allows for the early detection of any anomalies or wear that could affect tooling accuracy. Implementing a systematic inspection schedule, ideally at predefined intervals, ensures that potential issues are identified before they escalate. Tools such as micrometers and calipers can be used during these inspections to verify that dimensions remain within specified tolerances.

Calibration techniques are equally important in sustaining aerospace tolerance tooling. Calibration should be performed according to the manufacturer’s guidelines and should involve comparison against known reference standards. This practice not only aids in maintaining accuracy but also enhances the longevity of the tooling. For example, utilizing automated calibration equipment can significantly reduce human error and improve measurement consistency. Additionally, it is advisable to document all calibration procedures meticulously, maintaining a record that can provide insights into tooling performance over time.

Establishing a comprehensive maintenance schedule is essential for ensuring the integrity of aerospace tolerance tooling. This should include routine cleaning, lubrication of moving parts, and occasionally replacing parts that exhibit signs of wear. A proactive approach to maintenance can help avoid unexpected downtimes and increase the overall efficiency of production processes. It is also beneficial to train personnel on the best practices for handling and caring for these tools as improper use can lead to damage and inaccuracies.

By integrating these best practices—regular inspection, precise calibration techniques, and a structured maintenance schedule—manufacturers can enhance the reliability and functionality of aerospace tolerance tooling, ensuring that it meets the rigorous demands of the industry.

Success Stories in Aerospace Tolerance Tooling

Aerospace tolerance tooling plays a critical role in maintaining the precise dimensions and quality standards necessitated by the industry. Several case studies exemplify successful implementations of this approach, providing valuable lessons and insights for professionals involved in aerospace manufacturing and engineering.

One noteworthy example occurred at a leading aerospace manufacturer, which faced difficulties in producing aircraft wing components that consistently met stringent tolerance specifications. The production line was frequently plagued by variances, leading to increased rework times and elevated costs. In response, the company invested in advanced aerospace tolerance tooling technologies, including automated measurement systems and tailored fixtures. By implementing these solutions, the manufacturer reduced tolerances to within ±0.002 inches, significantly enhancing production efficiency and minimizing waste. The successful implementation of these tools not only ensured compliance with aerospace standards but also improved the overall reliability of the aircraft wing components.

Another compelling case involved a subcontractor specializing in the production of engine mounts for commercial jets. This manufacturer encountered challenges related to the assembly process, particularly in ensuring the precise alignment of critical components. To overcome these hurdles, the company integrated aerospace tolerance tooling with its existing workflows, utilizing specialized jigs and advanced gauging techniques. The result was a substantial 30% reduction in assembly time, while concurrently achieving a zero-defect rate during inspections. This success underscores the importance of utilizing comprehensive tooling systems to refine production processes and enhance product quality.

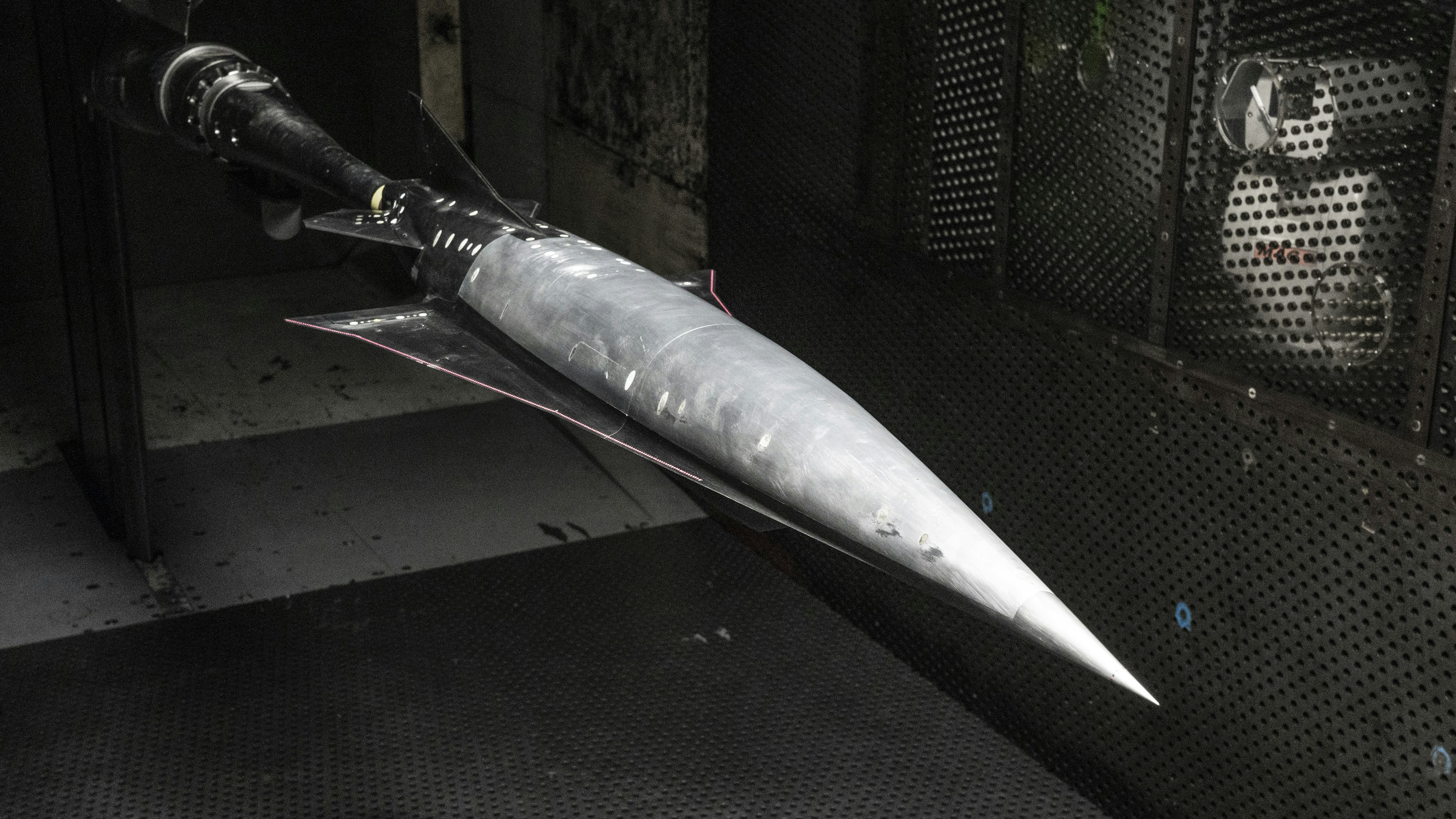

Lastly, a research initiative aimed at developing next-generation aerospace components highlighted the role of tolerance tooling in innovation. By employing 3D-printed prototypes equipped with adaptive tolerance tooling, researchers were able to explore previously unachievable geometries. This flexibility not only showcased the capabilities of modern aerospace materials but also paved the way for future advancements in aircraft design and performance.

Future Trends in Aerospace Tolerance Tooling

The aerospace industry is undergoing substantial transformations, driven by advancements in technology and increasing demands for sustainability. A significant trend that is shaping the future of aerospace tolerance tooling is the adoption of smart tooling. This innovative approach leverages the capabilities of the Internet of Things (IoT) and artificial intelligence (AI) to enhance precision and efficiency in manufacturing processes. Smart tools can monitor their performance in real-time, providing critical data to engineers and operators, thereby optimizing production workflows and reducing waste.

Moreover, sustainability has become a pivotal concern in the aerospace sector. This has led to the exploration of eco-friendly materials and manufacturing processes. Aerospace tolerance tooling will likely see a shift toward the use of advanced materials that not only meet stringent performance criteria but also maintain a lower environmental footprint. For instance, the integration of composite materials is expected to rise, as these materials offer a favorable strength-to-weight ratio while reducing overall energy consumption during production.

Another crucial development is the growing reliance on additive manufacturing, commonly known as 3D printing. This technology facilitates the creation of intricate geometries and complex components that were previously challenging to achieve with traditional manufacturing methods. As additive manufacturing becomes more prevalent, aerospace tolerance tooling will need to adapt to ensure accuracy and consistency in the final products. This may involve designing specialized tools and fixtures that accommodate the unique requirements of additive processes.

Alongside these advancements, the industry will face challenges such as meeting regulatory standards and ensuring that tooling innovations can be effectively integrated into existing production lines. However, by focusing on emerging trends such as smart tooling, sustainability, and advanced material usage, the aerospace sector can position itself to overcome these obstacles and continue to innovate effectively. In conclusion, the future of aerospace tolerance tooling looks promising as it embraces these trends and transforms the industry for the better.